Die washing device for integrated circuit packaging die

A technology for integrated circuits and moulds, which is applied to cleaning methods using tools, cleaning methods and utensils, and cleaning methods using liquids. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

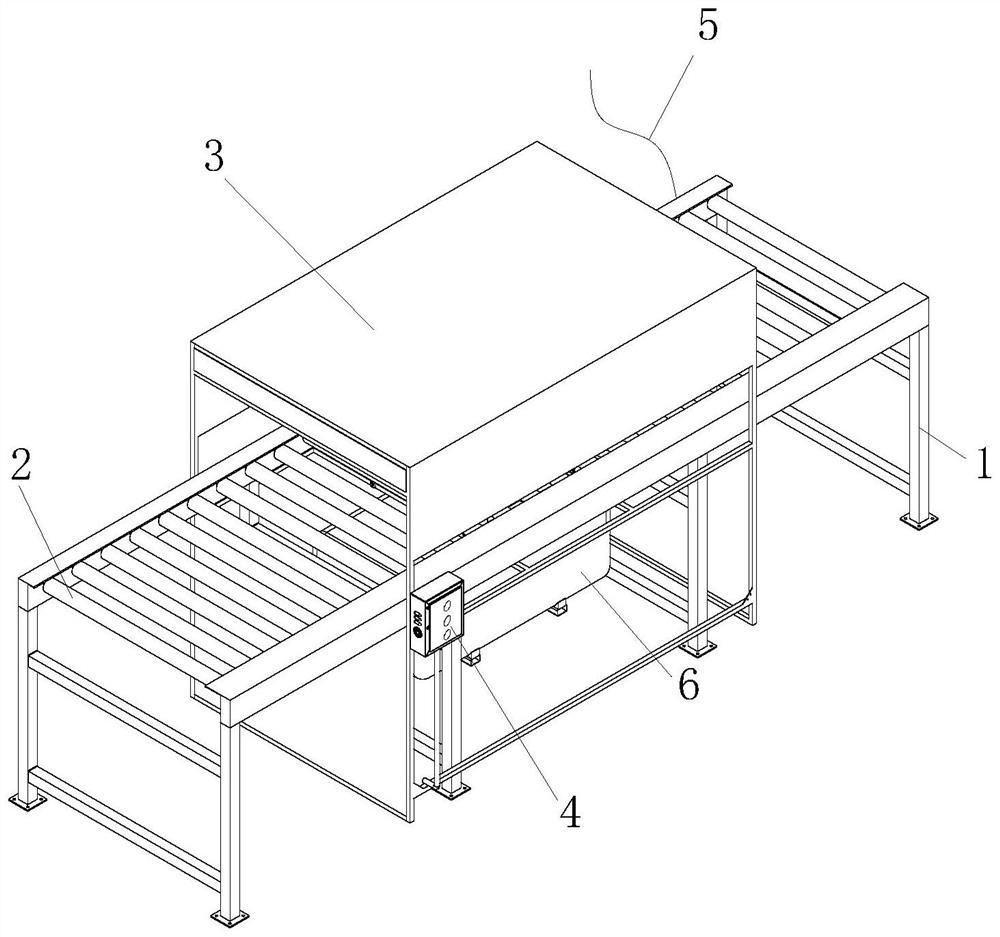

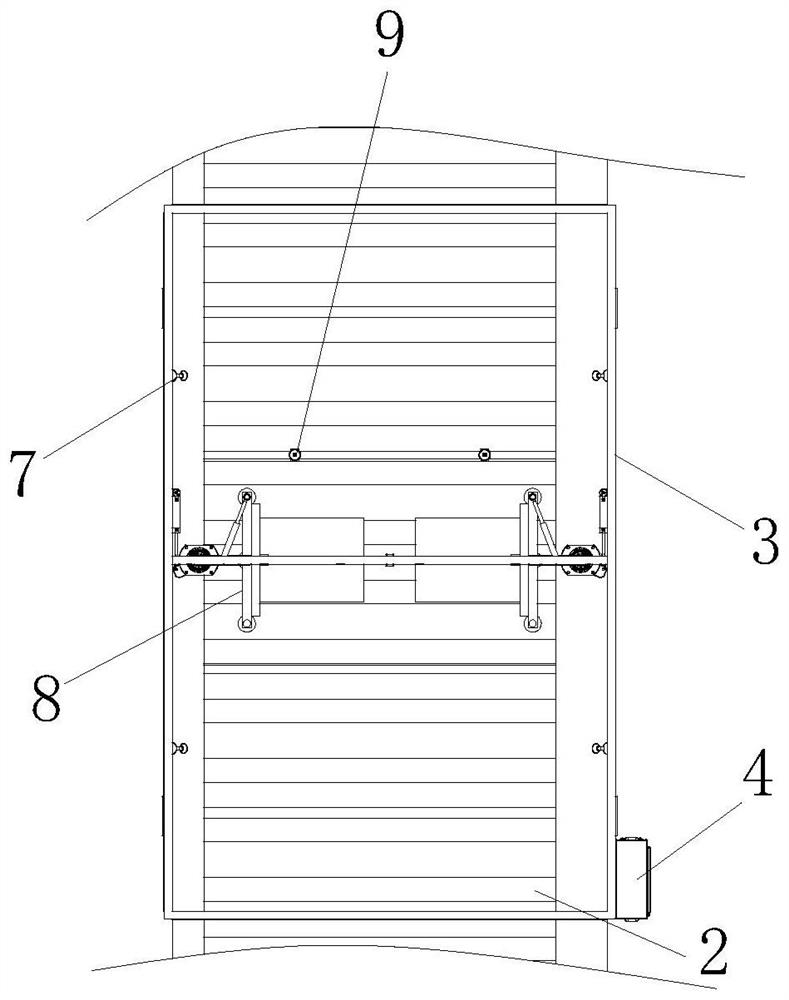

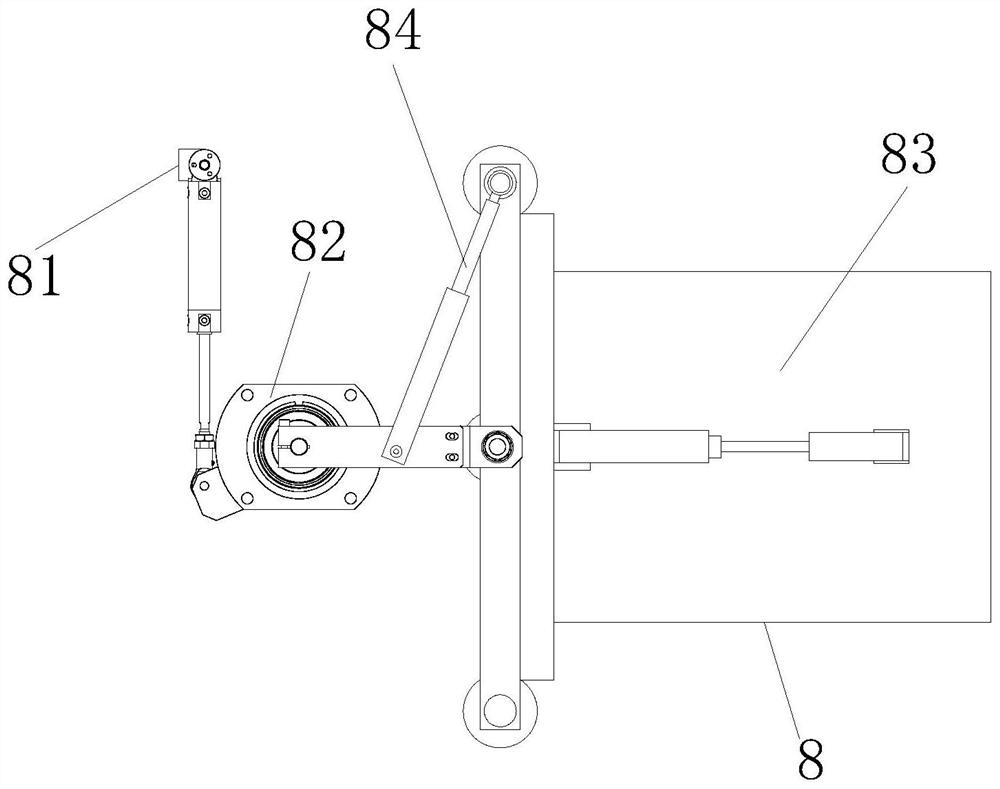

[0034] see figure 1 and figure 2 , the present invention provides a mold cleaning device for integrated circuit packaging molds by improvement, including a support frame 1, a transfer roller 2, a fixed frame 3, a control panel 4, a power supply wire 5, a circulation frame 6, a first nozzle 7 , the second nozzle 9 and the adjusting brushing mechanism 8, the inner side of the support frame 1 is provided with a transmission roller 2, the middle of the support frame 1 is provided with a fixed frame 3, the adjusting brushing mechanism 8 is installed on the inner side of the fixed frame 3, and the right end of the fixed frame 3 is provided with a The control panel 4, the rear end of the support frame 1 is fixed with a power supply wire 5, the bottom of the support frame 1 is installed with a circulation frame 6, the left and right sides of the fixed frame 3 are oppositely arranged with a first spray head 7, and the bottom of the support frame 1 and the second spray head 9 are conne...

Embodiment 2

[0041] The present invention provides a mold washing device for integrated circuit packaging molds by improving, the rotating shaft 824 runs through the inner side of the movable sleeve 825, which is beneficial to make the rotating shaft 824 rotate smoothly, and the swing arm 826 is in the shape of a flat strip. , which is beneficial to drive the brush plate mechanism 83 to move. There are two adjustment brush mechanisms 8, and the adjustment brush mechanisms 8 are arranged along the left and right sides of the fixed frame 3 relative to each other.

[0042] The present invention provides a mold cleaning device for an integrated circuit packaging mold through improvement, and its working principle is as follows;

[0043] First, before use, place the mold washing device for the integrated circuit packaging mold horizontally, so that the support frame 1 can support the device fixedly;

[0044] Second, when in use, connect the external power supply through the power lead 5 to prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com