Penetrating and inserting protection mechanism for mold

A protection mechanism and mold technology, applied in the field of injection molds, can solve problems such as affecting mold clamping accuracy, insufficient mold clamping accuracy, and prone to mold friction and fluff, so as to avoid mutual friction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

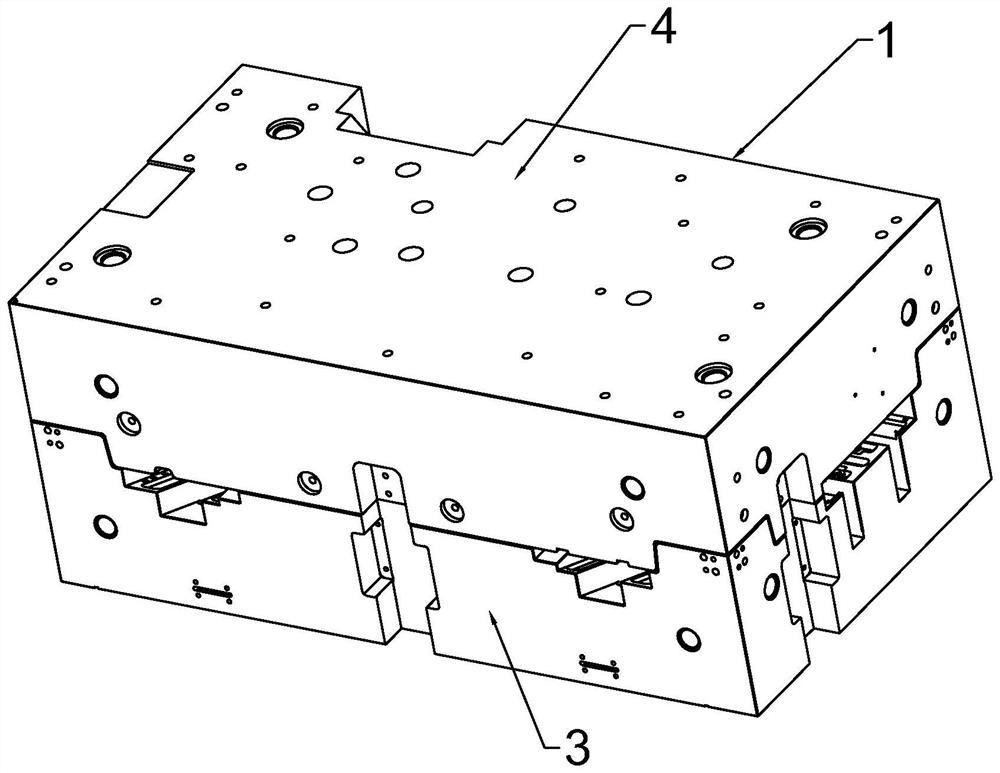

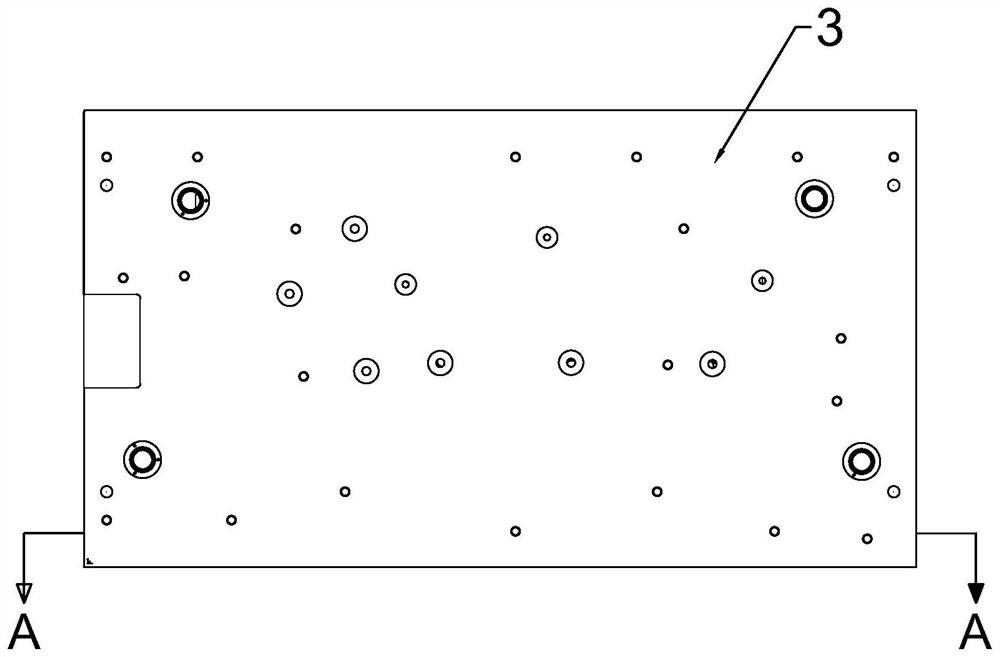

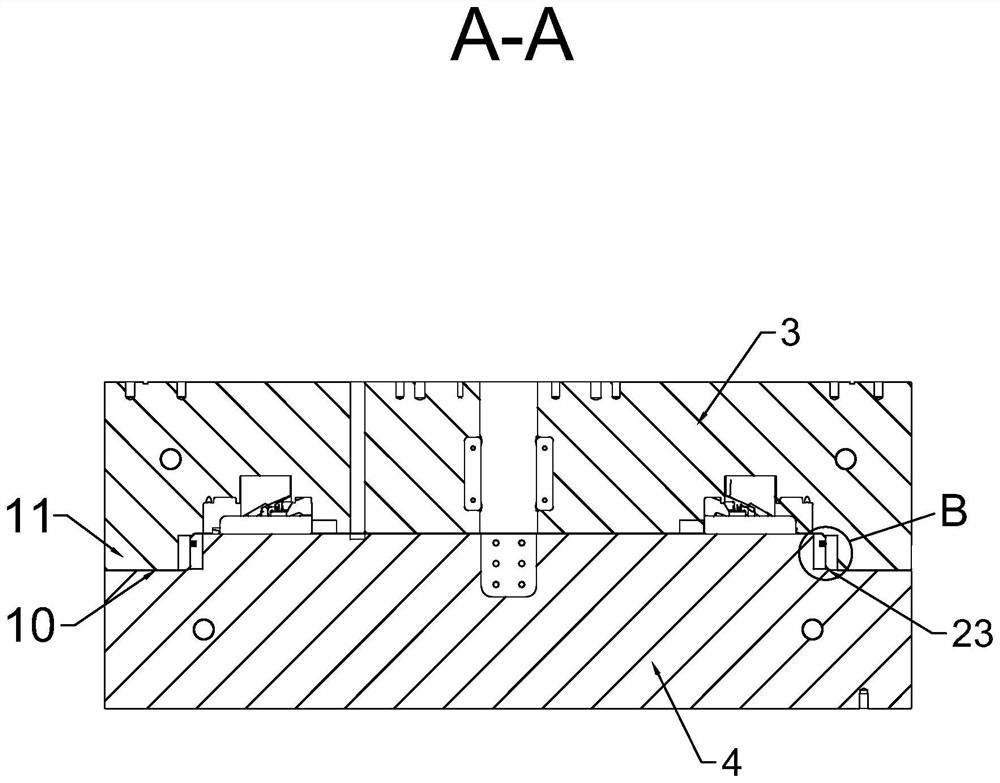

[0026] Example 1: A penetration protection mechanism for a mold (see attached Figure 1-7 ), including an early warning protection device 2 arranged on the mold body 1, the mold body includes an upper template 3 and a lower template 4, and the early warning protection device includes an insertion protection block 5, an early warning mechanism 6, The upper template is provided with interspersed wear-resistant blocks 7; after the upper template and the lower template are clamped, an inclined parting surface 8 is formed, and the inclination of the parting surface is greater than the interpenetration protection block and the lower template. The inclination of the parting surface 2 after the wear-resistant block is interspersed; the early warning mechanism 6 can give an early warning of the deviation of the clamping deviation during the clamping process of the upper template and the lower template, so that the lower template can be fine-tuned in time. , to avoid the mutual friction...

specific Embodiment 2

[0043] In this embodiment, a distance sensor is added on the basis of the specific embodiment 1. The distance sensor is installed on the rotating shaft of the sensor, and the distance sensor can detect the rotation distance of the friction wheel.

specific Embodiment 3

[0044] In this embodiment, on the basis of the specific embodiment 1, the interpenetrating protection block and the interpenetrating wear-resistant block are added with a height of 1 mm each to avoid space. It is beneficial to prevent the clamping interference of interspersed protective blocks and interspersed wear-resistant blocks when the upper and lower templates are clamped.

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com