Fragmented prefabricated assembly type mixed tower design method considering mold universality

A technology of prefabricated assembly and design method, which is applied in the assembly of wind turbines, the configuration of installation/support of wind turbines, and mechanical equipment, etc., can solve the problems of high cost of molds, construction efficiency and cost impact, etc., and achieve economical production. The effect of cost, shortened production period, and reduced quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

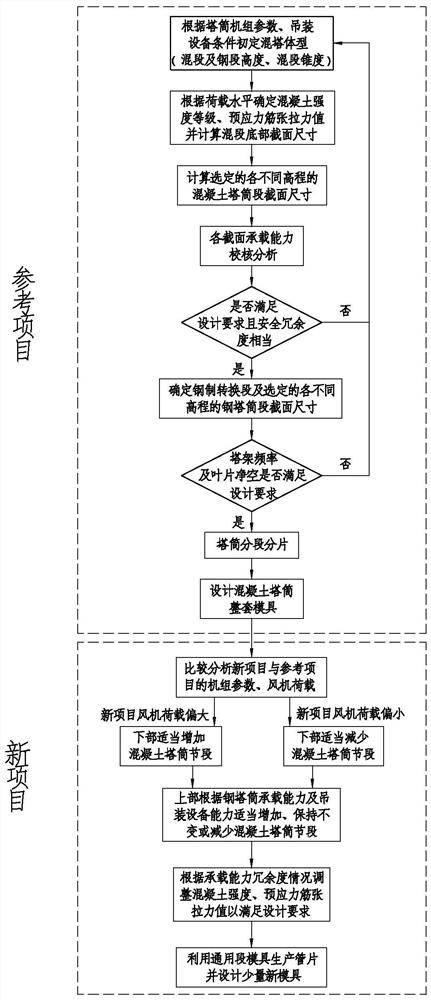

Method used

Image

Examples

Embodiment Construction

[0033] The reference items and new items in this embodiment are both steel-concrete composite towers with a hub height of 150m. The present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

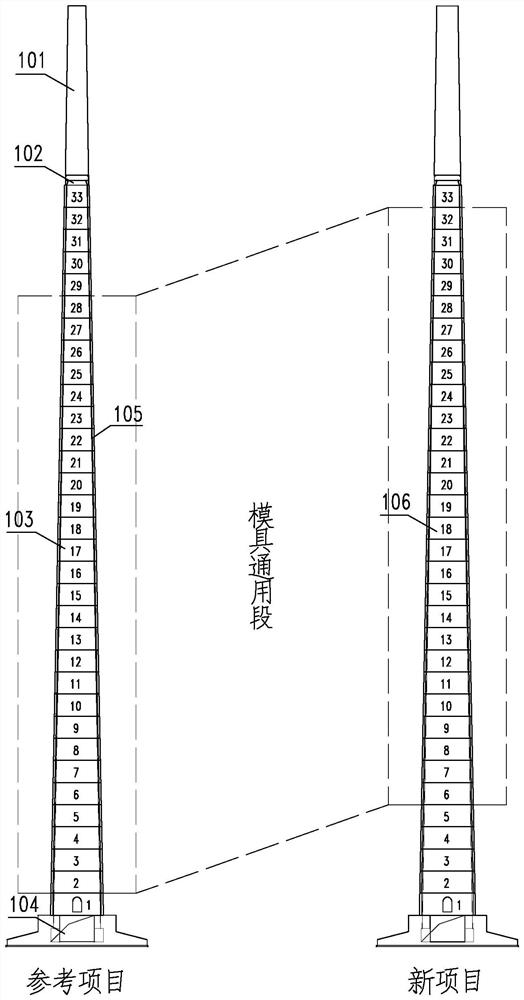

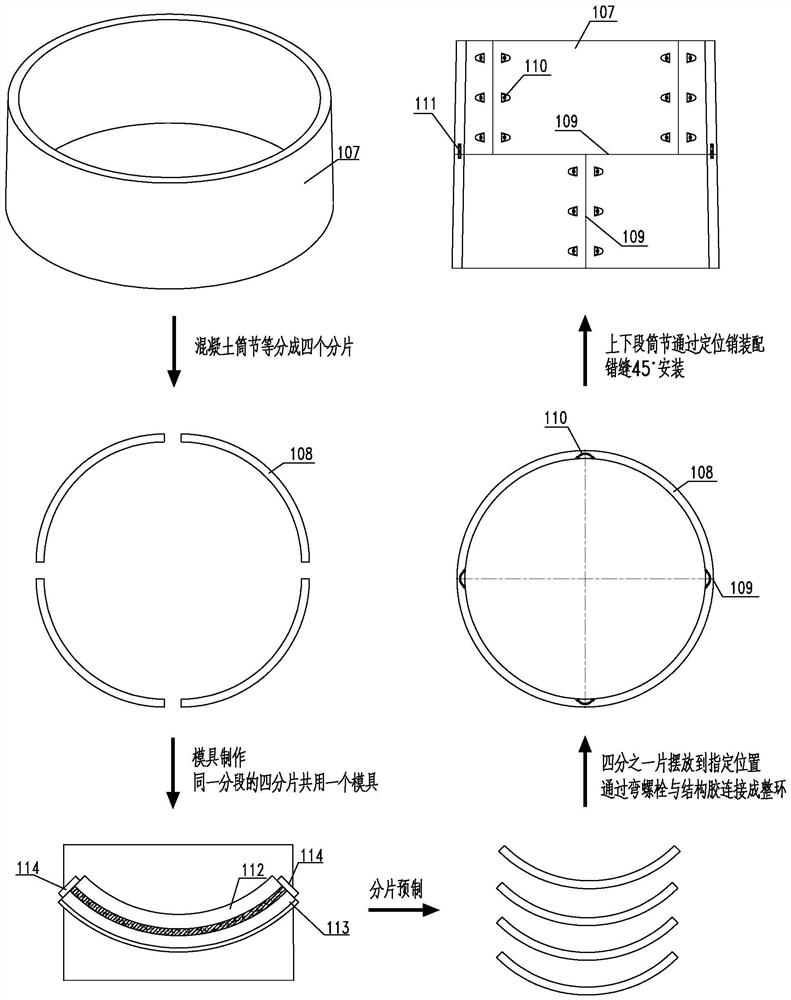

[0034] like figure 2 As shown in the figure, a segmented prefabricated mixed tower, the main structure of the tower is a concrete-steel combined structure. Taking the tower of the reference project as an example, it includes a top steel tower 101, a steel conversion section 102, Concrete tower 103 , bottom hollow fan foundation 104 and prestressed steel strand system 105 . The concrete tower 103 is in the shape of a cone, and is designed to be composed of cone sections with a height of 3.0m. The steel tower 101 and the steel-concrete transition section 102 are connected by high-strength bolt assemblies, and the steel-concrete transition section 102, the concrete tower 103 and the hollow fan foundation 104 are integ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com