Movable test wire fixing hanging point structure

A test line, mobile technology, applied in the direction of electrical components, etc., can solve the problems of easy fall off of wire clips, threats to the personal safety of test instruments or staff, waste, etc., and achieve the effect of convenient adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

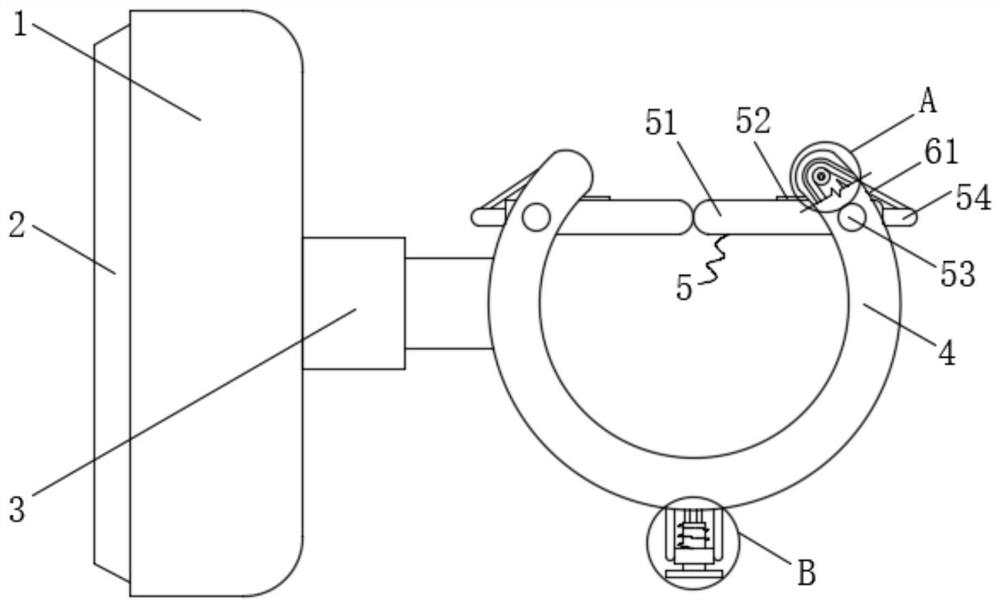

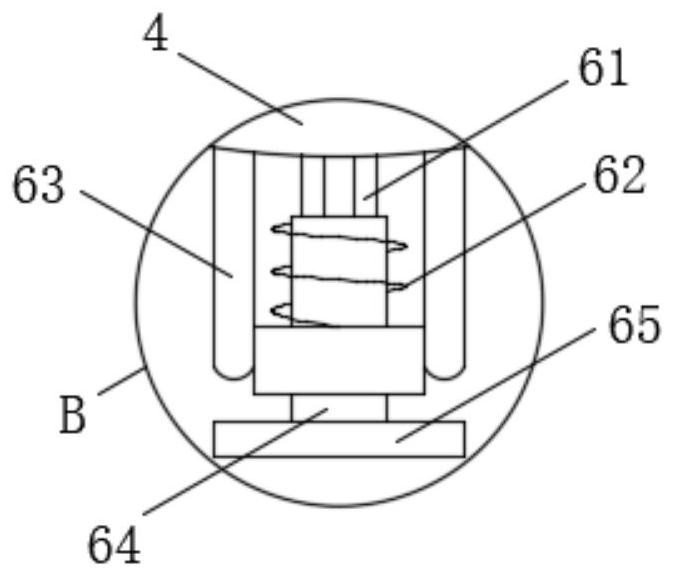

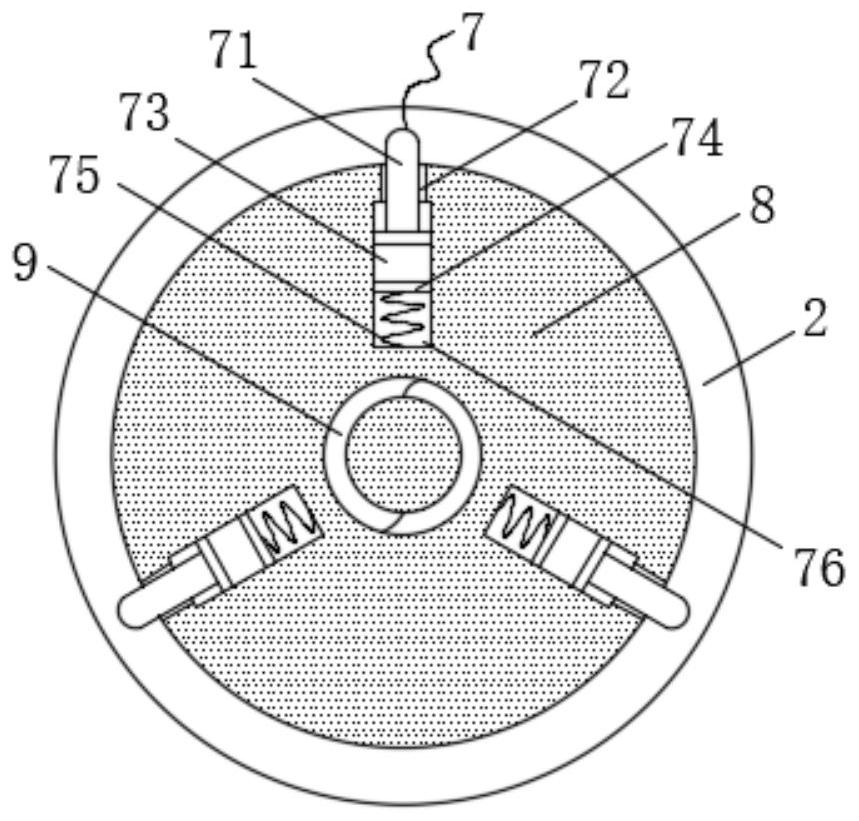

[0028] The specific embodiment is: by setting the limit mechanism 5 and the control mechanism 6, the two limit rods 51 can block the test wire to prevent the test wire from leaving the fixing ring 4, and at the same time, under the action of the torsion spring 53 and the blocking piece 52, the limit The rod 51 can be kept in a horizontal position to avoid the influence of the test line. When the control pull block 65 moves down, the sliding rod 64 can be pulled down, and the top end of the sliding rod 64 can pull the other end of the pulling rope 61. In the role of the guide wheel 67 The moving track of the pull rope 61 can be changed by pulling the connecting block 54 up and down, and the limit rod 51 can be moved down when the connecting block 54 is pulled up and down, and the two limit rods 51 no longer block the gap of the fixing ring 4. Take out, by setting the fixing rod 63 and the first spring 62, the fixing rod 63 can fix the sliding sleeve to achieve the fixing effect ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com