Structural steel and method for manufacturing same

A manufacturing method and technology for structure, which are applied to the normalizing heat treatment thick steel plate for structure and its manufacturing field, can solve the problems of unfavorable impact toughness at low temperature, coarse structure, undesired economy, etc., to ensure economical efficiency and excellent impact toughness at low temperature. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

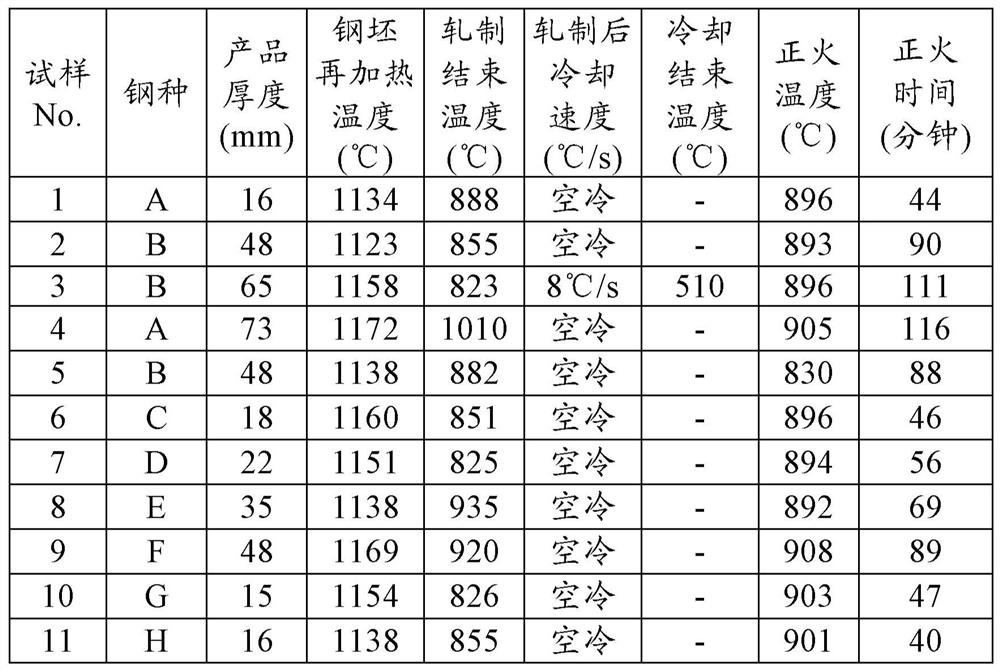

Examples

Embodiment Construction

[0039] The present invention relates to a steel material for structural use and a method for manufacturing the same, and preferred embodiments of the present invention are described below. The embodiments of the present invention can be modified and implemented in various ways, and it should not be understood that the scope of the present invention is limited to the embodiments described below. The present embodiments are provided to describe the present invention in further detail to those of ordinary skill in the art to which the present invention pertains.

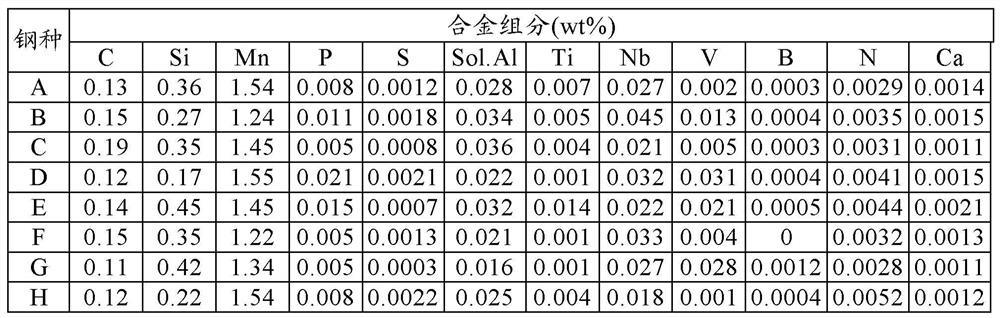

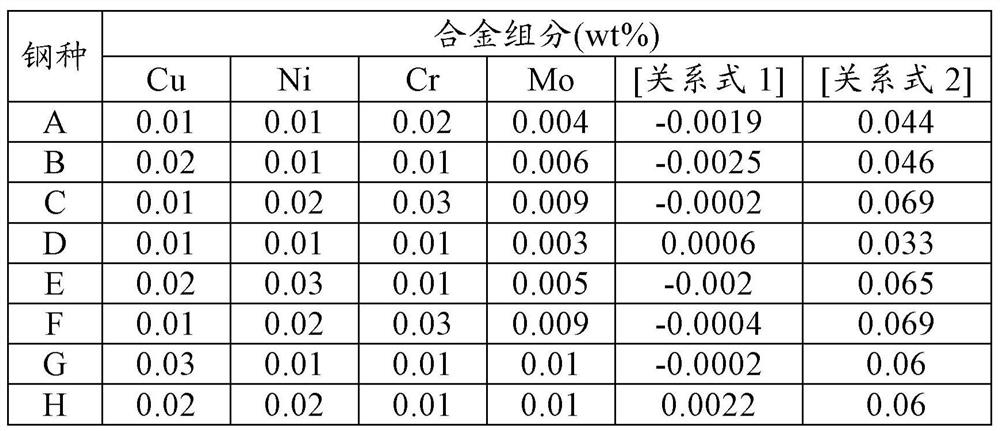

[0040] Hereinafter, the reasons for limiting the alloy composition of the present invention will be described more specifically. Unless specifically stated otherwise, % and ppm related to alloy components are by weight.

[0041] The steel material for structural use according to one aspect of the present invention may contain, in % by weight, C: 0.12-0.18%, Si: 0.02-0.5%, Mn: 0.6-1.6%, Sol.Al: 0.002-0.06% , Nb: 0.001 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com