Production method of quenching and tempering type 27 SiMn abrasion-resistant steel plate

A wear-resistant steel plate and a production method technology, applied in the metallurgical field, can solve the problems of prolonging the equipment manufacturing cycle and increasing the cost, and achieve the effects of uniform and fine structure, reduced manufacturing cycle and moderate strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

[0011] Embodiment 1-4: The production method of the quenched and tempered 27SiMn wear-resistant steel plate adopts the following process.

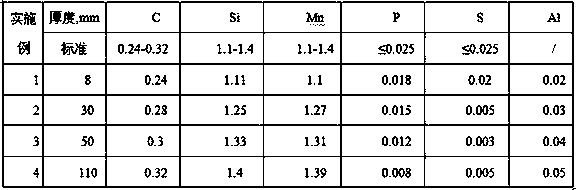

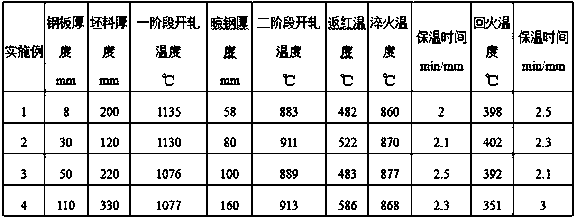

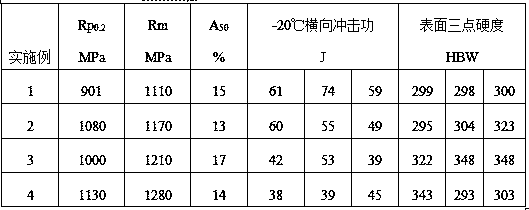

[0012] (1) Production process: including rolling, quenching and tempering processes; the rolling process: the first stage rolling temperature is 1050-1150°C, the thickness of the air-dried steel plate is the thickness of the steel plate + 50mm; the second stage rolling temperature is 880~930℃; water cooling after rolling, reddening temperature is 400℃~600℃; the compression ratio of billet and steel plate is ≥3. The quenching process: the quenching temperature is 850°C-880°C, the holding time is 2-2.50min / mm, and water cooling after holding the heat. The tempering process: the tempering temperature is 350-450° C., the holding time is 2.5-3.0 min / mm, and air cooling after the heat preservation can obtain the wear-resistant steel plate. See Table 1 for the standard of the steel plate and the corresponding components of the steel plate of eac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com