Gas shielded welding wire for EH47 crack arrest steel

A technology of gas shielded welding wire and crack arrest, which is applied in the direction of welding medium, welding equipment, welding/cutting medium/material, etc. It can solve the problems that the strength cannot meet the requirements of EH47, toughness and crack arrest performance can not meet the requirements, and achieve excellent The effect of fracture toughness and excellent low temperature impact toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with embodiment.

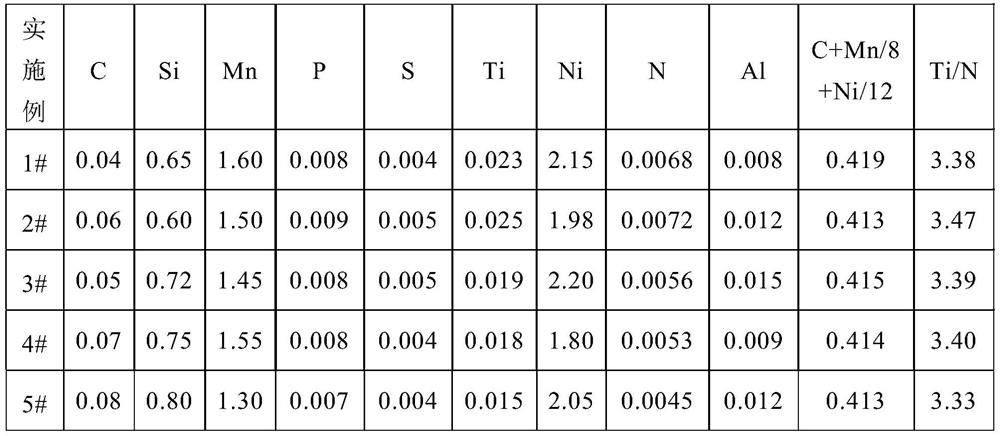

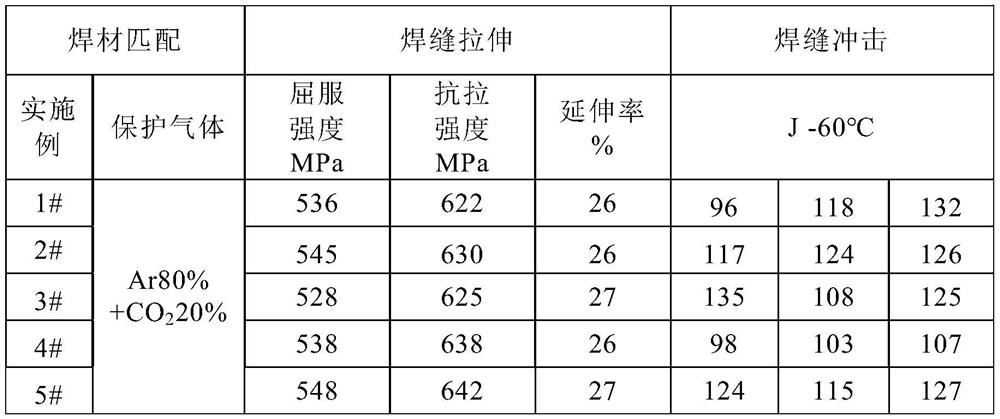

[0028] According to the chemical composition scope of the present invention, smelting 5 furnaces of welding wire steel (the welding wire composition is as shown in Table 1), is drawn into the welding wire of diameter 1.2mm, adopts Ar80%+CO 2 20% mixed gas shielded welding, welding current 260-290A, welding voltage 27-31V, welding speed 33cm / min. The properties of weld deposited metal are shown in Table 2 and Table 3.

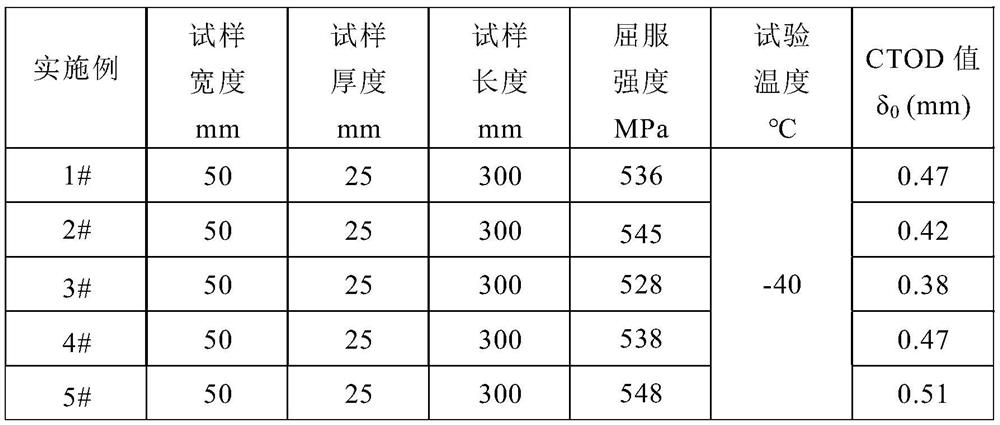

[0029] The test results show that the embodiment of the present invention meets the performance requirements and fracture toughness requirements of EH47 crack arrest steel.

[0030] Table 1 Chemical composition of welding wire, unit: wt%

[0031]

[0032] Table 2 Tensile and impact properties of weld metal

[0033]

[0034] Table 3 Weld metal CTOD value

[0035]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com