Municipal water supply and drainage pipeline cleaning equipment

A pipeline cleaning, water supply and drainage technology, applied in the direction of cleaning hollow objects, cleaning methods and utensils, separation methods, etc., can solve the problems of increasing the difficulty of cleaning again, cleaning is not clean, etc., to improve the convenience of adjustment, improve the filtering effect, and ensure The effect of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

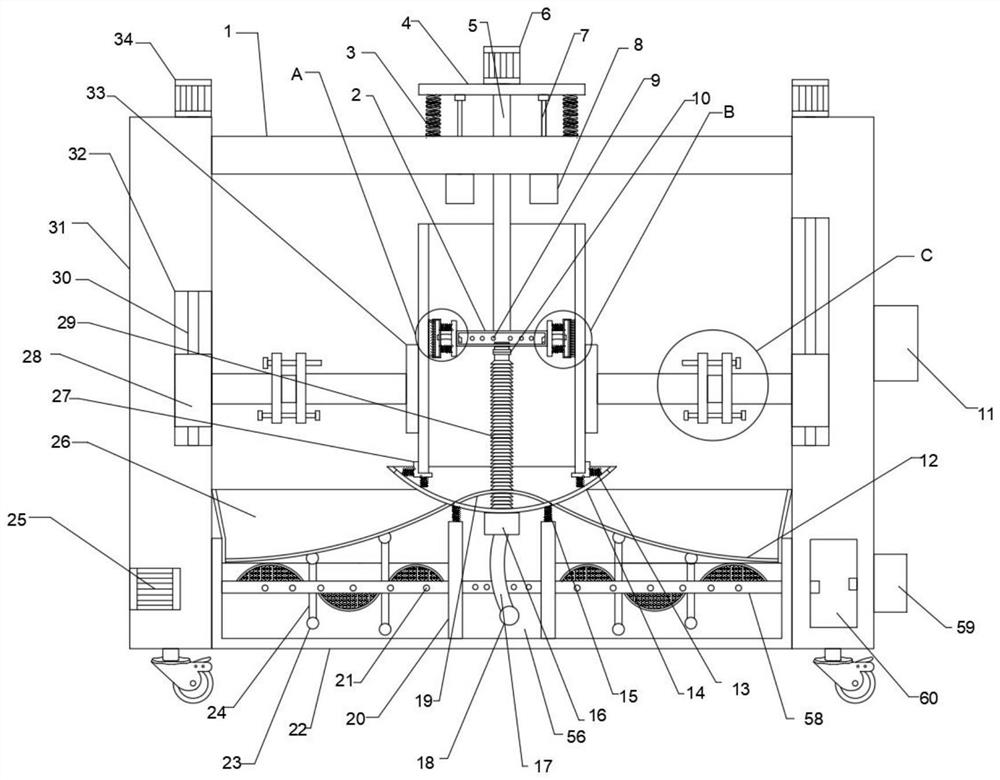

[0031]Referring to the drawings, a municipal water supply and drainage pipeline cleaning equipment includes a horizontal plate, the outer walls at both ends of the horizontal plate are fixedly connected with side plates, the bottom of the horizontal plate is provided with a pipe, the inner wall of the pipe is provided with a rotating box, the A first cleaning mechanism is arranged on the outer wall of one end of the rotating box, and a second cleaning mechanism is arranged on the outer wall of the other end of the rotating box. The outer walls of both ends are provided with splints, the other end of the splint is provided with a telescopic mechanism, the other end of the telescopic mechanism is provided with a height adjustment mechanism, the bottom of the pipe is provided with a bearing mechanism, and the two ends of the side plate are fixedly connected with a Bottom box, the inner wall of the bottom box is provided with a filtering mechanism, and the liquid supply mechanism i...

Embodiment

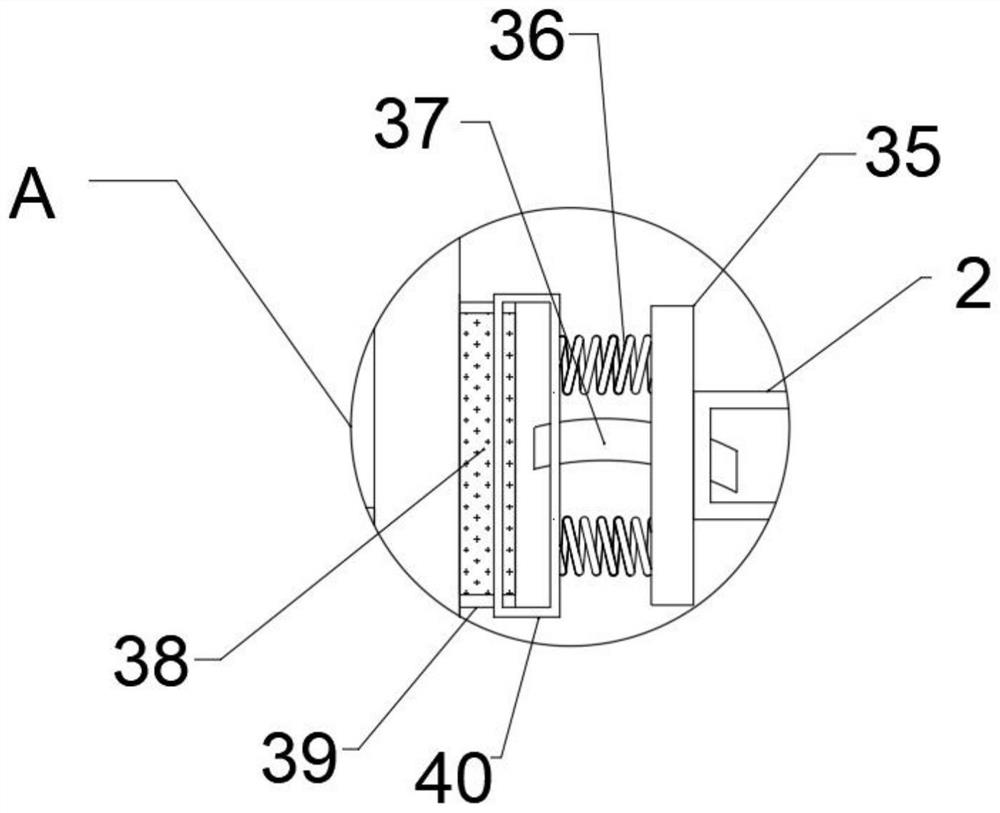

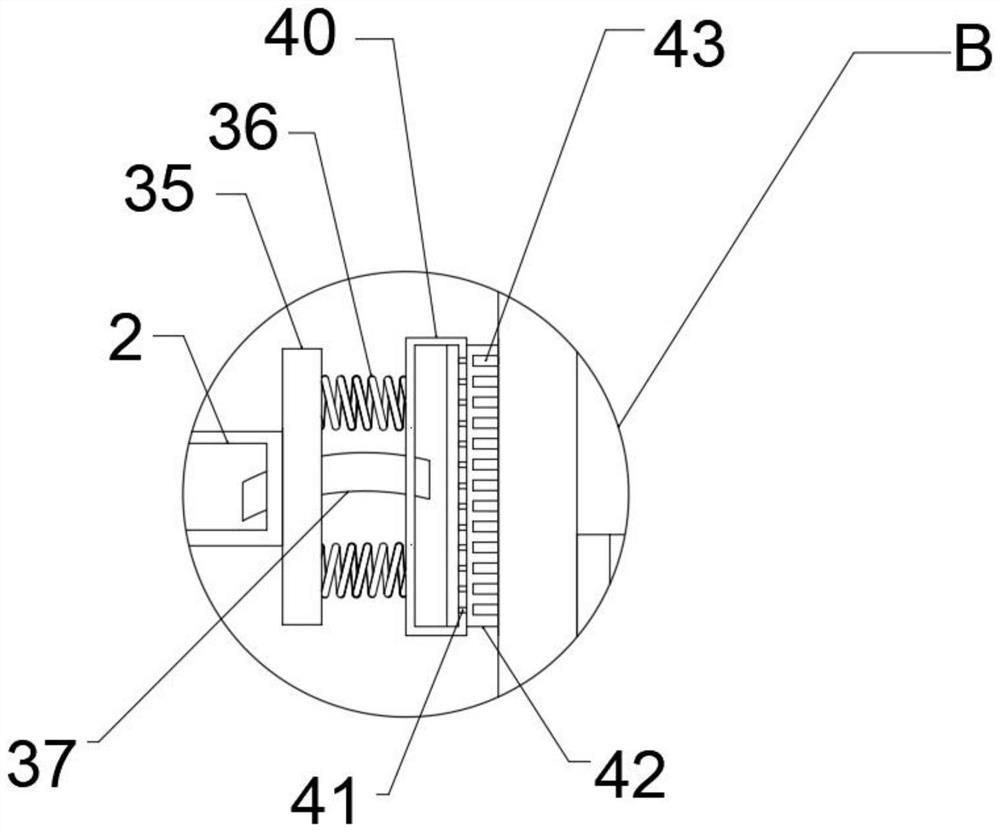

[0041] Referring to the figure, a municipal water supply and drainage pipeline cleaning equipment, the outer wall of the other end of the second connecting rod is fixedly connected with a fourth connecting plate, the outer wall of the other end of the fourth connecting plate is fixedly connected with a fifth spring, and the other end of the fifth spring and the splint Fixed connection, the outer wall of one end of the fourth connecting plate is fixedly connected with a cylinder.

[0042] When in use, the splint and the fourth connecting plate are connected by a fifth spring, so that the pipeline has the ability to move elastically, and the inclination angle of the splint and its pipeline can be adjusted by setting the air cylinder to achieve the purpose of multi-angle cleaning.

[0043] Example

[0044] Referring to the figure, a municipal water supply and drainage pipeline cleaning equipment, the bottom of the third spring is fixedly connected with a partition, both ends of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com