Pipe orifice leakage treatment construction method based on drainage pipe

A construction method and drainage pipe technology, which are applied in the sewer system, waterway system, water supply device, etc., can solve the problem of reducing the plugging and treatment effect of the leakage of the nozzle, and the leakage of the nozzle cannot be kept closed for a long time, Problems such as the unreliable combination of water blocking glue at the seepage can improve the effect of water blocking treatment, ensure the effect of embedding and sealing, and facilitate the test

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

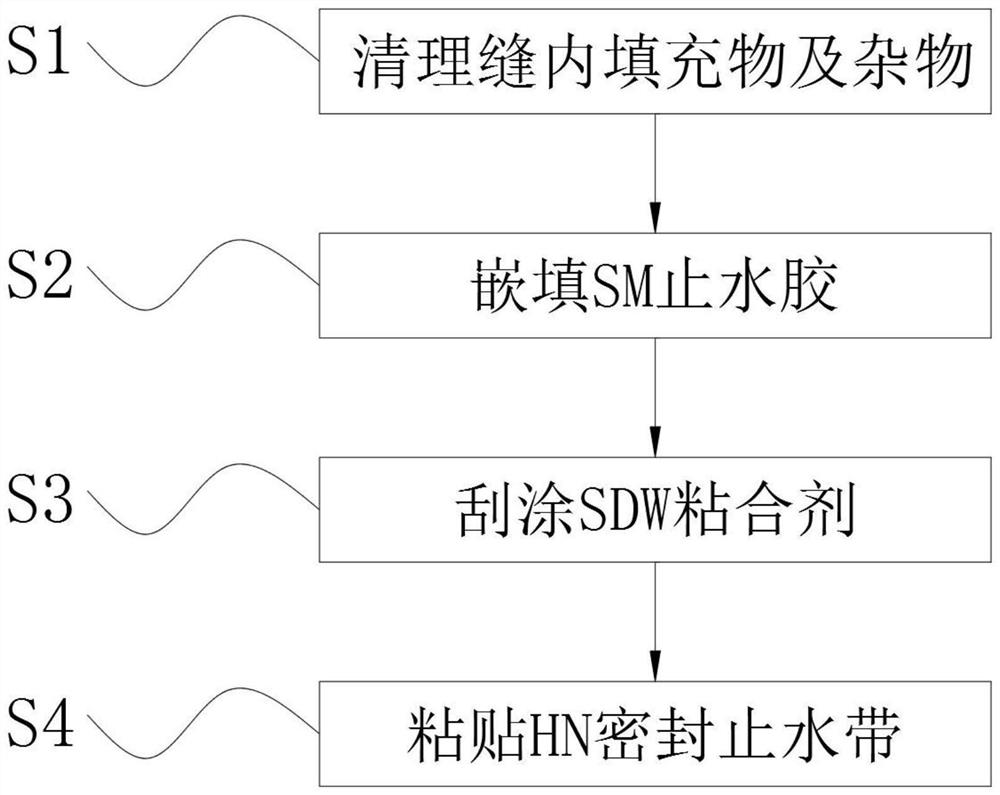

[0036] Example 1: as figure 1 As shown in the figure, the present invention provides a technical solution, a construction method based on the leakage of the drain pipe. Leakage of pipe joints;

[0037] The construction method of nozzle leakage control specifically includes the following steps:

[0038] S1. Clean up the fillings and sundries in the seam;

[0039] S2, embedded with SM water-stop glue;

[0040] S3. Scratch SDW adhesive;

[0041] S4, paste HN sealing waterstop;

[0042] SM Waterstop Adhesive can be directly used on ashless concrete surface, its surface can be rough or flat, can be used on dry surface or wet base surface, avoid long-term contact with water , to prevent the SM glue from expanding in advance;

[0043] HN sealing waterstop is a high-quality seam sealing waterstop system. It is composed of HN sealing waterstop, two-component epoxy adhesive SD and SM lap adhesive. HN sealing waterstop is mainly The sealing water stop used for seams can be used on...

Embodiment 2

[0059] Example 2: as figure 1 As shown in the figure, the present invention provides a technical solution, a construction method based on the leakage of the drain pipe. Leakage of pipe joints;

[0060] The construction method of nozzle leakage control specifically includes the following steps:

[0061] S1. Clean up the fillings and sundries in the seam;

[0062] S2, embedded with SM water-stop glue;

[0063] S3. Scratch SDW adhesive;

[0064] S4, paste HN sealing waterstop;

[0065] SM Waterstop Adhesive can be directly used on ashless concrete surface, its surface can be rough or flat, can be used on dry surface or wet base surface, avoid long-term contact with water , to prevent the SM glue from expanding in advance;

[0066] HN sealing waterstop is a high-quality seam sealing waterstop system. It is composed of HN sealing waterstop, two-component epoxy adhesive SD and SM lap adhesive. HN sealing waterstop is mainly The sealing water stop used for seams can be used on...

Embodiment 3

[0082] Example 3: as figure 1 As shown in the figure, the present invention provides a technical solution, a construction method based on the leakage of the drain pipe. Leakage of pipe joints;

[0083] The construction method of nozzle leakage control specifically includes the following steps:

[0084] S1. Clean up the fillings and sundries in the seam;

[0085] S2, embedded with SM water-stop glue;

[0086] S3. Scratch SDW adhesive;

[0087] S4, paste HN sealing waterstop;

[0088] SM Waterstop Adhesive can be directly used on ashless concrete surface, its surface can be rough or flat, can be used on dry surface or wet base surface, avoid long-term contact with water , to prevent the SM glue from expanding in advance;

[0089] HN sealing waterstop is a high-quality seam sealing waterstop system. It is composed of HN sealing waterstop, two-component epoxy adhesive SD and SM lap adhesive. HN sealing waterstop is mainly The sealing water stop used for seams can be used on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com