Iron ore detector for geological exploration

A geological exploration and detector technology, applied in the field of geological exploration, can solve the problems of manpower consumption and inability to improve the search efficiency, and achieve the effect of convenient excavation, reducing manpower operation and solving manpower consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

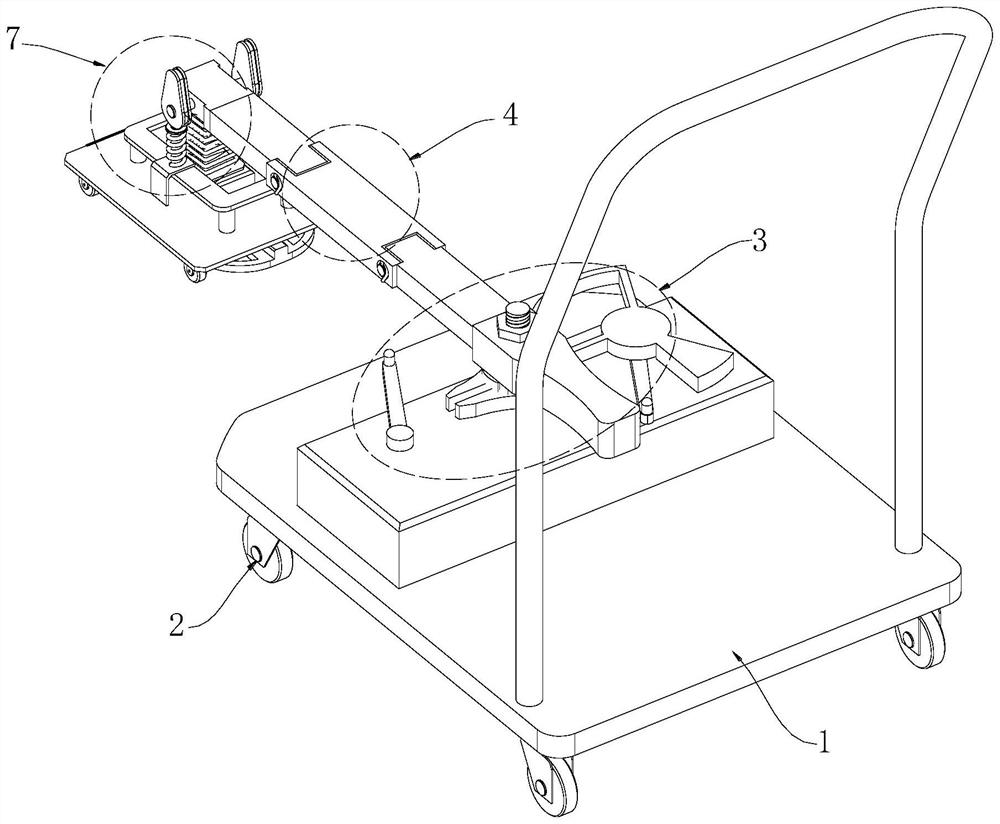

[0044] The support plate 1 is provided with a driving member 3, the driving end of the driving member 3 is provided with a swing rod 4, and the end of the swing rod 4 away from the driving member 3 is provided with an iron ore detection head 5 for detecting the position of the iron ore;

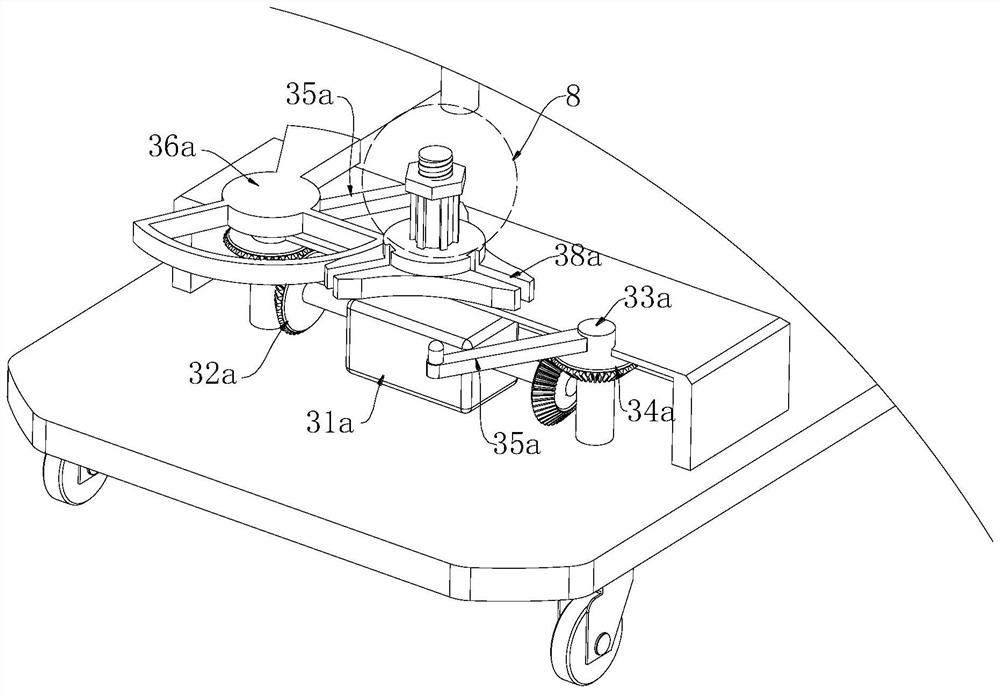

[0045]The driving member 3 includes a biaxial motor one 31a mounted on the support plate 1. The output end of the biaxial motor one 31a is provided with a driving gear 32a, and the end of the mounting seat 31b close to the driving gear 32a is provided with a rotating shaft 33a. A driven gear 34a is provided, and the driving gear 32a meshes with the driven gear 34a;

[0046] The rotating shaft 33a passes through the top of the mounting seat 31b and is respectively connected with a toggle rod 35a, and the top of any group of toggle rods 35a is provided with a matching ring 36a;

[0047] A passive ring 37a is arranged at the middle position of the mounting seat 31b, and a toggle groove 38a is op...

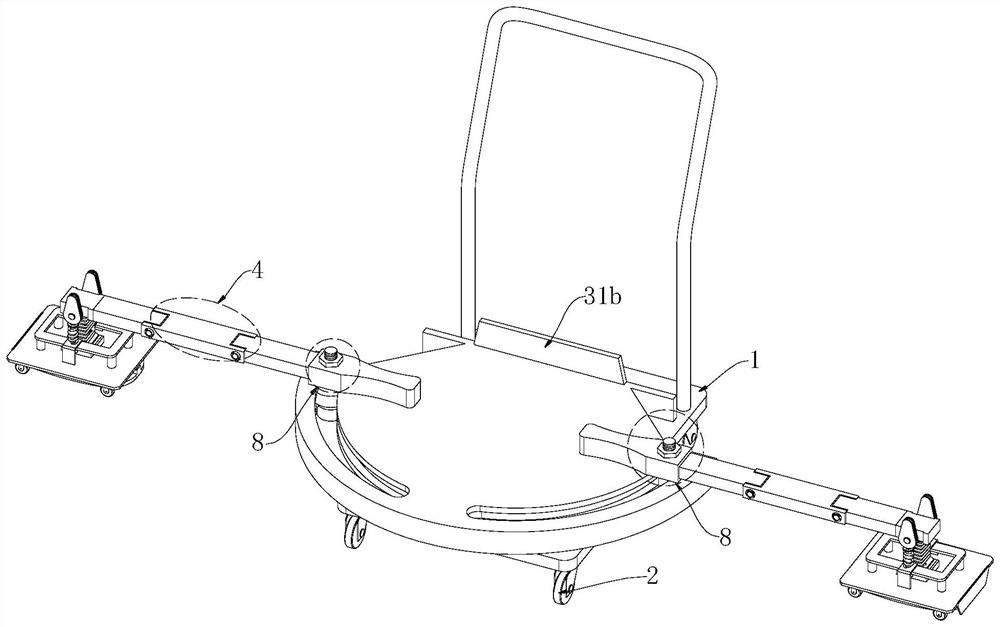

Embodiment 2

[0064] The driving member 3 includes a mounting seat 31b installed on the support plate 1, and two sets of sliding grooves 32b are opened on the mounting seat 31b. The sliding groove 32b is provided with a moving block 1 33b, the moving block one 33b is connected with the swing rod 4, and the moving block one 33b is connected. A detachable connecting piece 8 is provided between the swing rod 4;

[0065] One end of the mounting seat 31b is provided with a rotating motor 34b, the output end of the rotating motor 34b is provided with a threaded rod 35b, the threaded rod 35b is provided with a second moving block 36b, the moving block one 33b is movably connected with the moving block two 36b, and the moving block two A limiter 9 is arranged between 36b and the mounting seat 31b;

[0066] The limiting member 9 includes a connecting block 91 mounted on the mounting seat, and a limiting slot 92 is defined on the connecting block 91;

[0067] The two sides of the moving block 36b ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com