Contact connection auxiliary structure for microswitch

A technology of auxiliary structure and micro switch, which is applied in the direction of contact electrical connection, contact, parts of flip switch/rocker switch, etc., which can solve the problem of circuit disconnection, poor current flow and unstable circuit connection of the switch and other problems, to achieve the effect of increasing the contact area, avoiding unstable circuit connection, and realizing conversion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

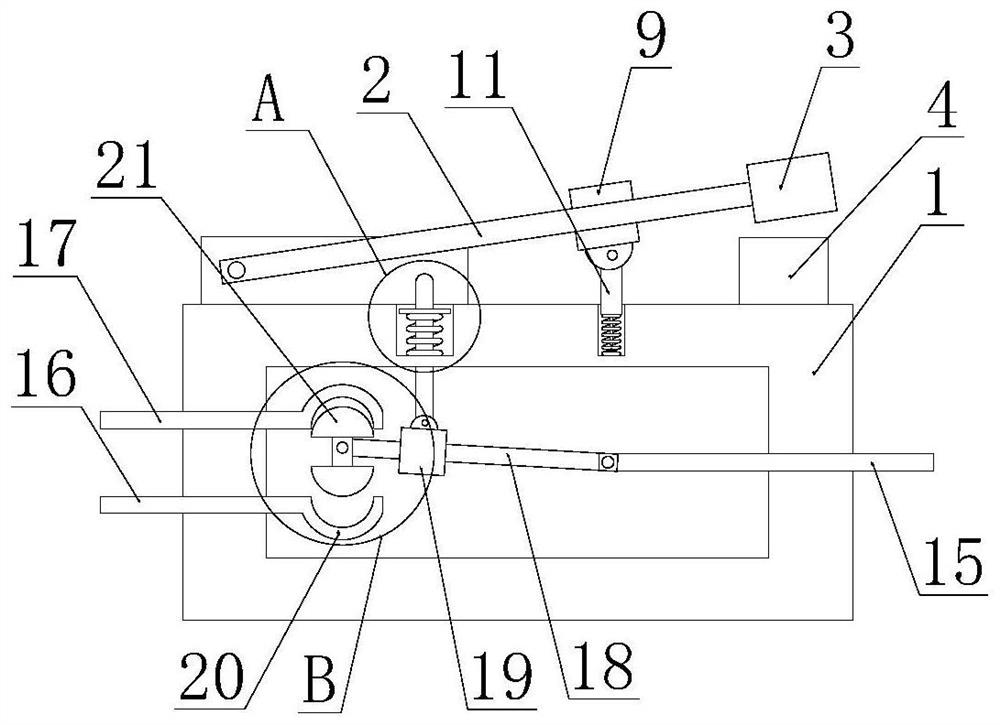

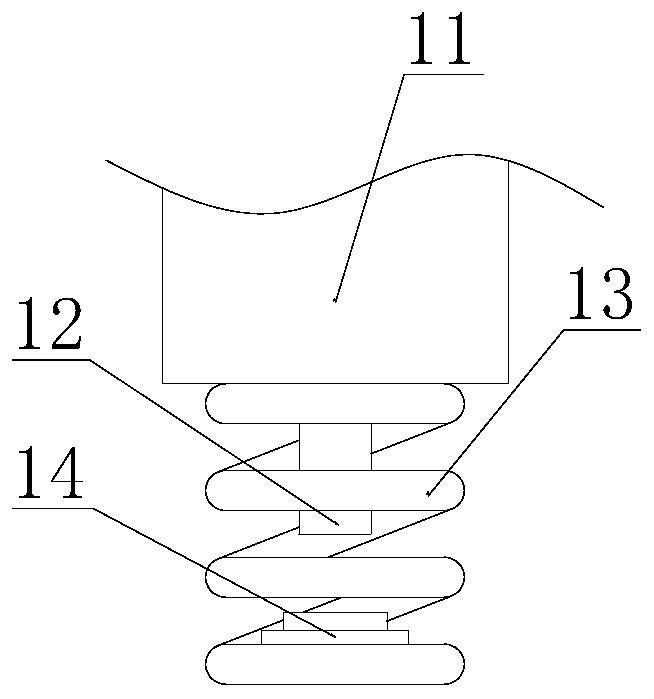

[0023] like Figure 1-2 and Figure 4 As shown, this specific embodiment adopts the following technical solutions: a contact connection auxiliary structure for a micro switch, comprising a housing 1, and a touch rocker 2 is rotatably connected to one end of the top of the housing 1, and the touch rocker 2. An iron block 3 is fixedly connected to one end away from the rotating shaft, and an electromagnet 4 is fixedly connected to the top of the casing 1 and one end close to the iron block 3. The electromagnet 4 is magnetically connected to the iron block 3 and is adsorbed by the electromagnet 4 The iron block 3 reduces the force required to press and touch the rocker 2, and avoids unstable circuit connection due to insufficient pressing force, wherein, the end of the rocker 2 close to the iron block 3 is cut with a chute 10, so The chute 10 is slidably connected with an I-shaped slider 9, the bottom of the I-shaped slider 9 is rotatably connected with a connecting rod 11, and ...

Embodiment 2

[0027] like figure 1 , image 3 As shown, this specific embodiment adopts the following technical solutions:

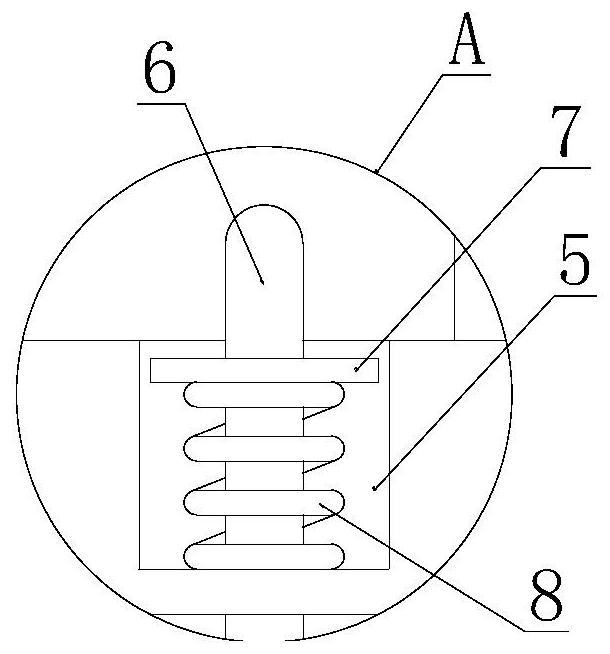

[0028] A telescopic slot 5 is excavated on the top of the casing 1 near the rotating shaft of the rocker 2, and a transmission rod 6 is inserted into the telescopic groove 5, and the transmission rod 6 extends to the inside of the casing 1; The casing 1 is provided with a telescopic groove 5 at the position relative to the transmission rod 6 , and one end of the transmission rod 6 is located inside the telescopic groove 5 and is fixedly connected to a limit plate 7 , and the bottom of the limit plate 7 is fixed between the bottom of the telescopic groove 5 A No. 1 spring 8 is connected, and one end of the transmission rod 6 is located inside the casing 1 with a No. 2 slider 19 . Connection, the No. 2 slider 19 is made of insulating material. When the transmission rod 6 is squeezed, the No. 2 slider 19 is driven to descend. The location of the access point.

[0029...

Embodiment 3

[0031] like figure 1 and Figure 5 As shown, this specific embodiment adopts the following technical solutions: one end of the housing 1 close to the electromagnet 4 is fixedly connected with a common wiring board 15, and one end of the housing 1 away from the electromagnet 4 is fixedly connected with a normally closed wiring board 16 and Normally open wiring board 17, between the common wiring board 15 and the normally closed wiring board 16 and the normally open wiring board 17 are provided with conductive rods 18 and conductive contacts 21, wherein the conductive rods 18 and the common wiring board 15 rotate Connecting, the normally closed wiring board 16 and the normally open wiring board 17 are located inside the casing 1 and both ends are fixedly connected with a U-shaped connecting piece 20, the concave surfaces of the two U-shaped connecting pieces 20 are opposite, and the conductive contacts 21 are located at between the two U-shaped connecting pieces 20 .

[0032] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com