Connector device and pre-stressed prefabricated piece

A technology for connecting joints and prefabricated parts, used in construction, sheet pile walls, infrastructure engineering and other directions, can solve the problems of high processing difficulty and cost of buckle cylinders, reduced pull-out and tensile capacity, and high firmness and hardness of elastic sheets. Achieve the effect of avoiding the drop of pullout resistance, avoiding stress damage, and improving reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

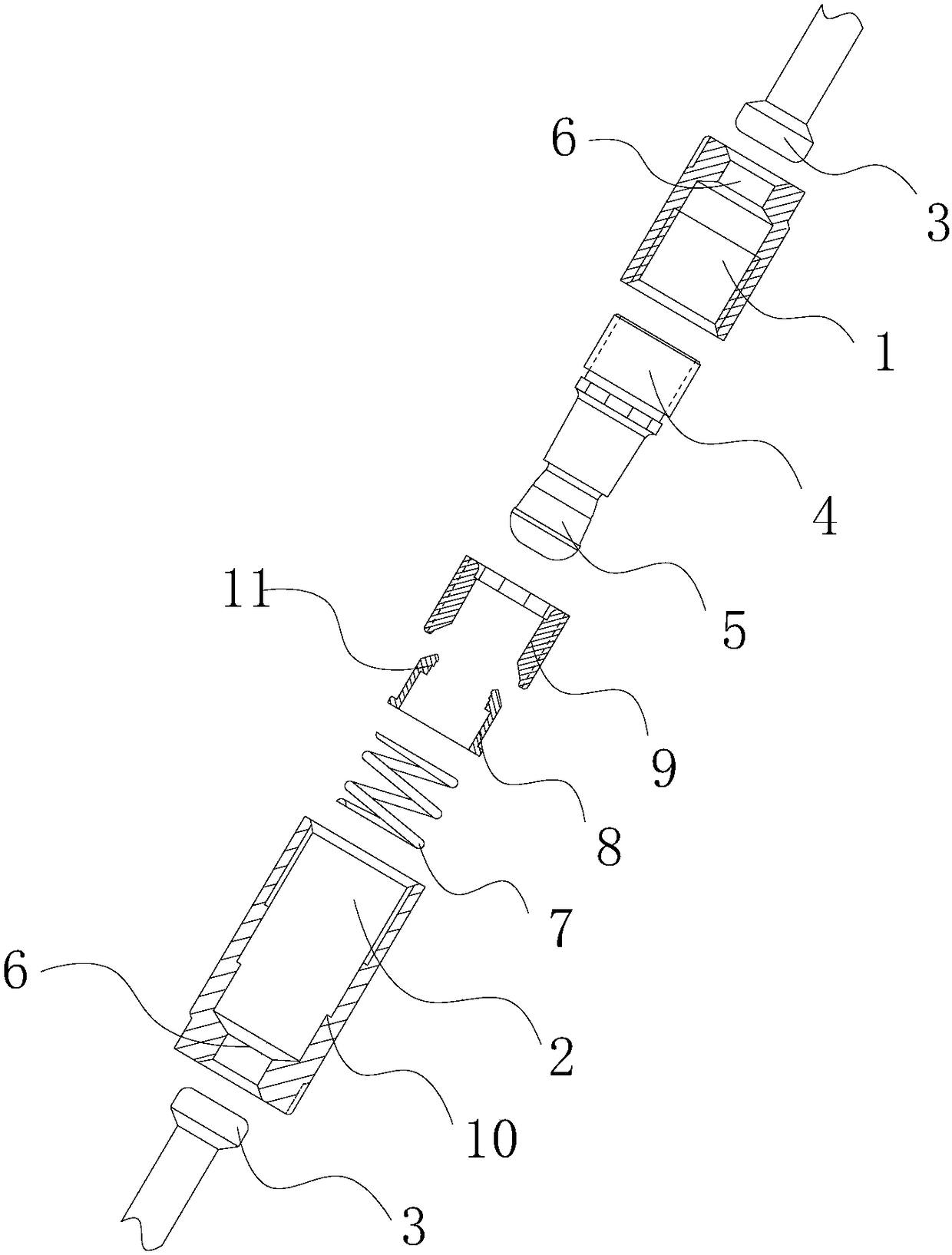

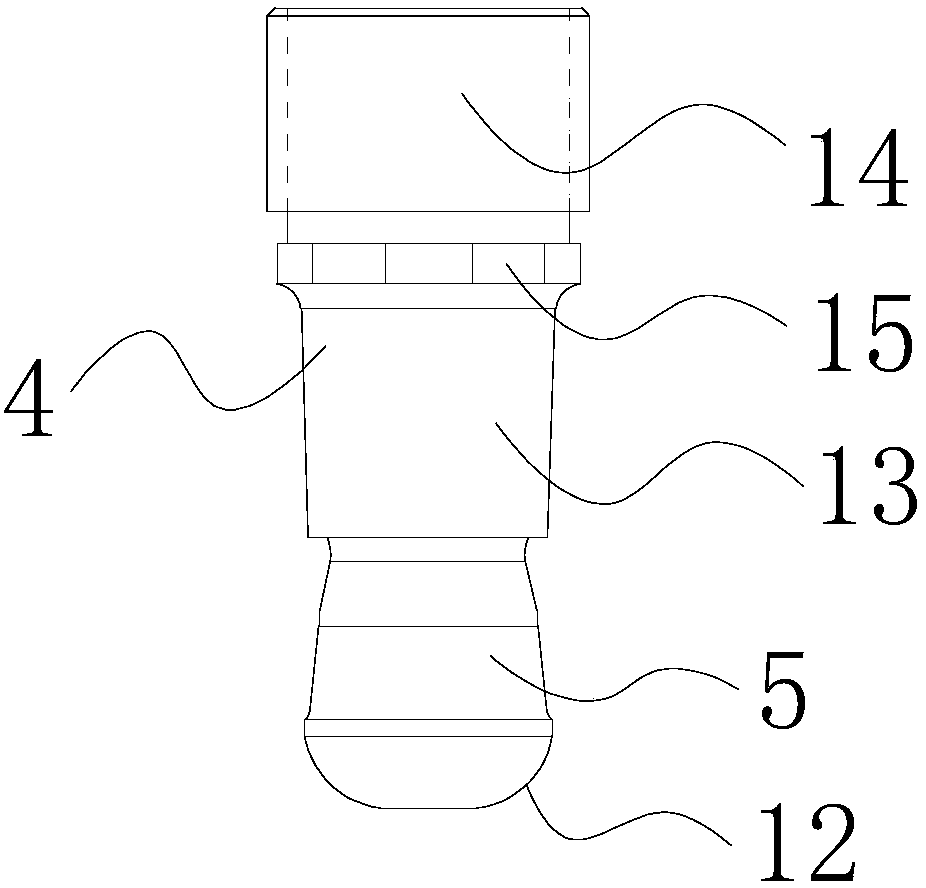

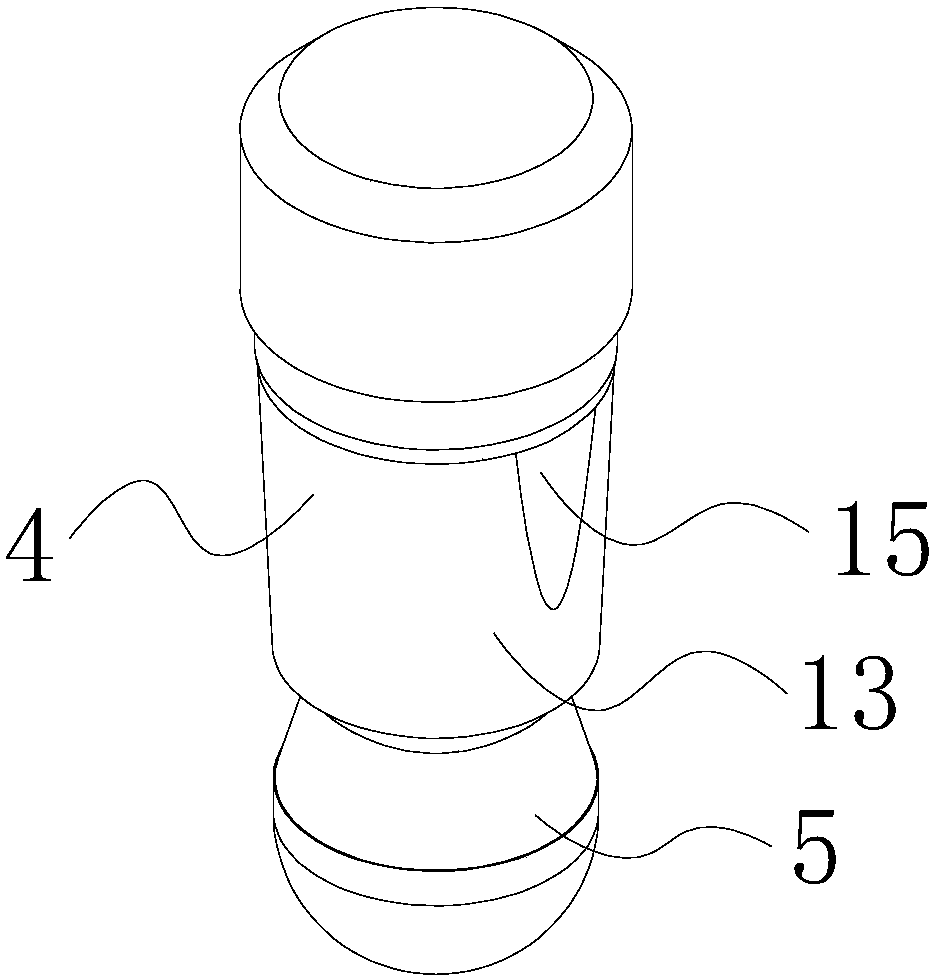

[0030] Such as figure 1 As shown, the present invention provides a connecting joint device, which includes an upper nut 1 and a lower nut 2, and the bottoms of the upper nut 1 and the lower nut 2 are provided with rib holes 6 for clamping with the rigid expansion head 3 , the end of the upper nut 1 away from the rib hole 6 is threadedly connected with an insertion rod 4, the insertion rod 4 is provided with a plug joint 5, and the lower nut 2 is arranged in turn with an elastic element 7, a buckle barrel 8 and a limit nut away from the rib hole 6 9. The buckle barrel 8 is provided with a card platform 11, wherein the inner cavity of the lower nut 2 is provided with a limiter 10, and the limiter 10 limits the displacement of the buckle barrel 8 to the direction of the rib hole 6, so that the insertion The joint 5 stretches the card platform 11 on the buckle barrel 8 and inserts the largest part 16 of the connector through the card platform and opens its minimum part 17 .

[00...

Embodiment 2

[0040] Such as Figure 8 As shown, the present invention also discloses a prestressed prefabricated part, including a first prestressed prefabricated part 20, a second prestressed prefabricated part 21 and a The connecting joint device of the prefabricated part 21, the end faces of the first prestressed prefabricated part 20 and the second prestressed prefabricated part 21 are equal in size, and the interfaces are opposite. The connecting joint device is the connecting joint device of embodiment 1, wherein the prestressed prefabricated Several longitudinal ribs 22 and transverse ribs in the part constitute the rigid skeleton of the prefabricated part. The longitudinal ribs 22 are generally evenly arranged in a regular pattern such as a circle or a square in the prestressed prefabricated part. The two ends of the longitudinal ribs 22 of the prestressed prefabricated part They are respectively manufactured as rigid expansion heads 3, and are respectively connected to the upper n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com