Knitting machine mesh wire pushing operation device and knitting machine

A technology of mesh wire and running device of a weaving machine, applied in the field of weaving machines, which can solve the problems of increasing the number of driving devices of the weaving machine, increasing production and later maintenance costs, and poor pushing effect, so as to ensure the weaving effect of the mesh wire, stable The effect of push and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

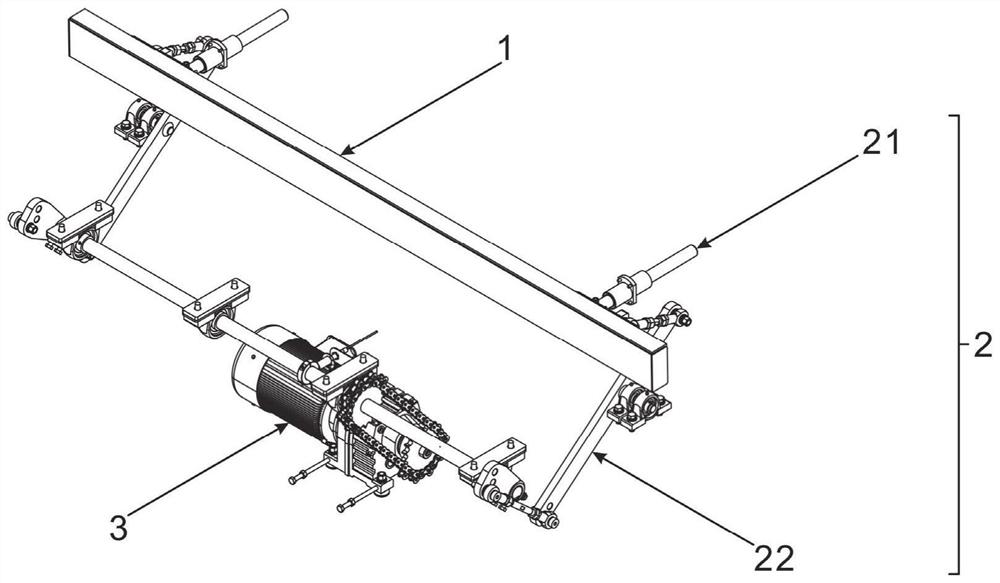

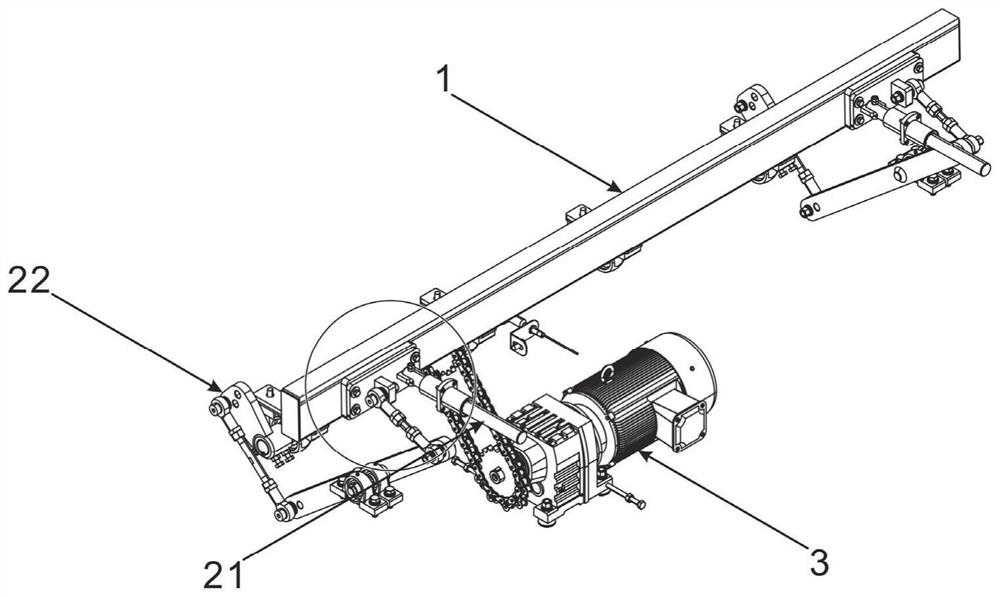

[0029] The invention provides a knitting machine mesh wire push running device, such as figure 1 and figure 2 As shown, the mesh wire pushing operation device of the knitting machine includes a mesh wire pushing mechanism 1 , a reciprocating transmission mechanism 2 and a driving mechanism 3 .

[0030] The linear reciprocating guide mechanism 21 is connected to the mesh wire pushing mechanism 1 , and the linear reciprocating guiding mechanism 21 can effectively limit the moving path of the mesh thread pushing mechanism 1 so that it can only move in a straight line.

[0031] The mesh pushing mechanism 1 is connected with the driving mechanism 3 through the reciprocating transmission mechanism 22 , and the reciprocating transmission transmission mechanism 22 can effectively convert the rotational power output by the driving mechanism 3 , thereby providing the mesh pushing mechanism 1 with a reciprocating pushing force.

[0032] The linear reciprocating guide mechanism 21 and t...

Embodiment 2

[0035] Embodiment 2 is built on the basis of embodiment 1:

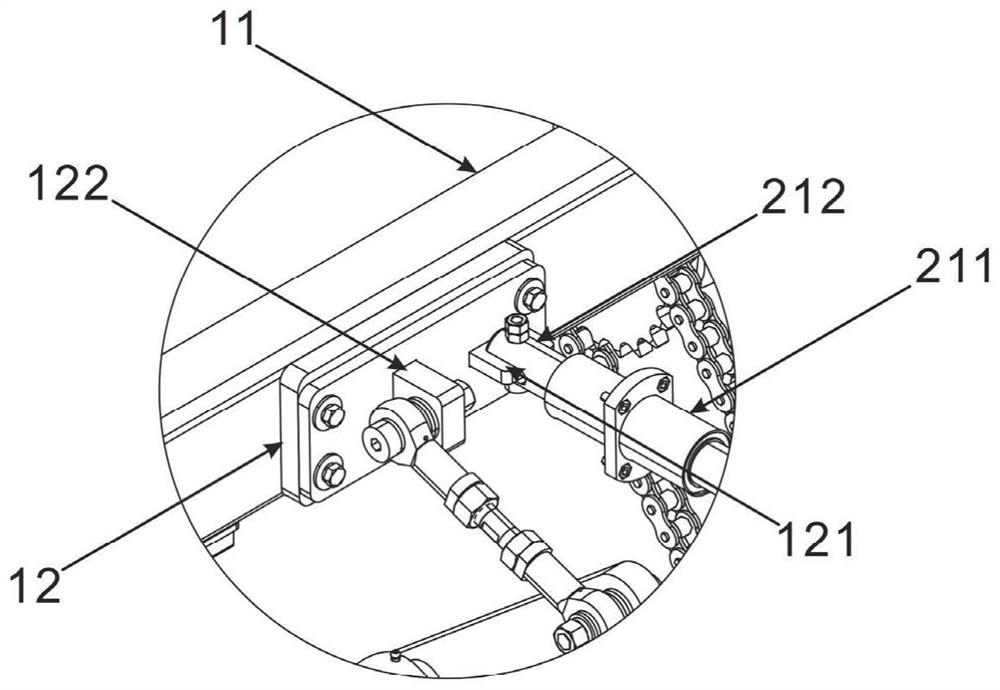

[0036] like image 3 As shown, the mesh pushing mechanism 1 includes a push plate assembly 11 and a push plate connecting piece 12 , and the push plate assembly 11 is connected with the push plate connecting piece 12 .

[0037] The push plate assembly 11 includes a rectangular support tube, the front side of the rectangular support tube is provided with a push plate, the top side and both ends of the rectangular support tube are provided with sealing plates, and the push plate connector 12 is connected to the rectangular support tube. the back side of the tube.

[0038] The push plate assembly 11 is an actuator for pushing the mesh wire, and directly pushes the mesh wire through a linear reciprocating motion.

[0039] A first connecting portion 121 and a second connecting portion 122 are provided on the side of the push plate connecting member 12 away from the push plate assembly 11 , which are used to connect the ...

Embodiment 3

[0066] Embodiment 3 is built on the basis of embodiment 2:

[0067] The present invention provides a knitting machine, such as Figure 5 As shown, the braiding machine includes a mesh wire pushing and running device of the braiding machine.

[0068] The mesh wire pushing operation device of the knitting machine is arranged on the knitting machine body 4, and the mesh wire pushing mechanism 1 is located on the work surface of the knitting machine body 4. The worktable moves back and forth in a straight line in the front and rear directions.

[0069] The braiding machine has various models and specifications, and a corresponding number of push plate connectors 12 and reciprocating transmission mechanisms 2 are provided according to different models and specifications.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com