Automatic elevating and horizontally-moving device for vegetable-cleaning box

An automatic lifting and translation device technology, applied in the direction of transportation, packaging, conveyors, etc., can solve the problems of difficult control, reduced conveying efficiency, short life, etc., and achieve the effect of convenient disassembly and maintenance, ensuring stability and high pushing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

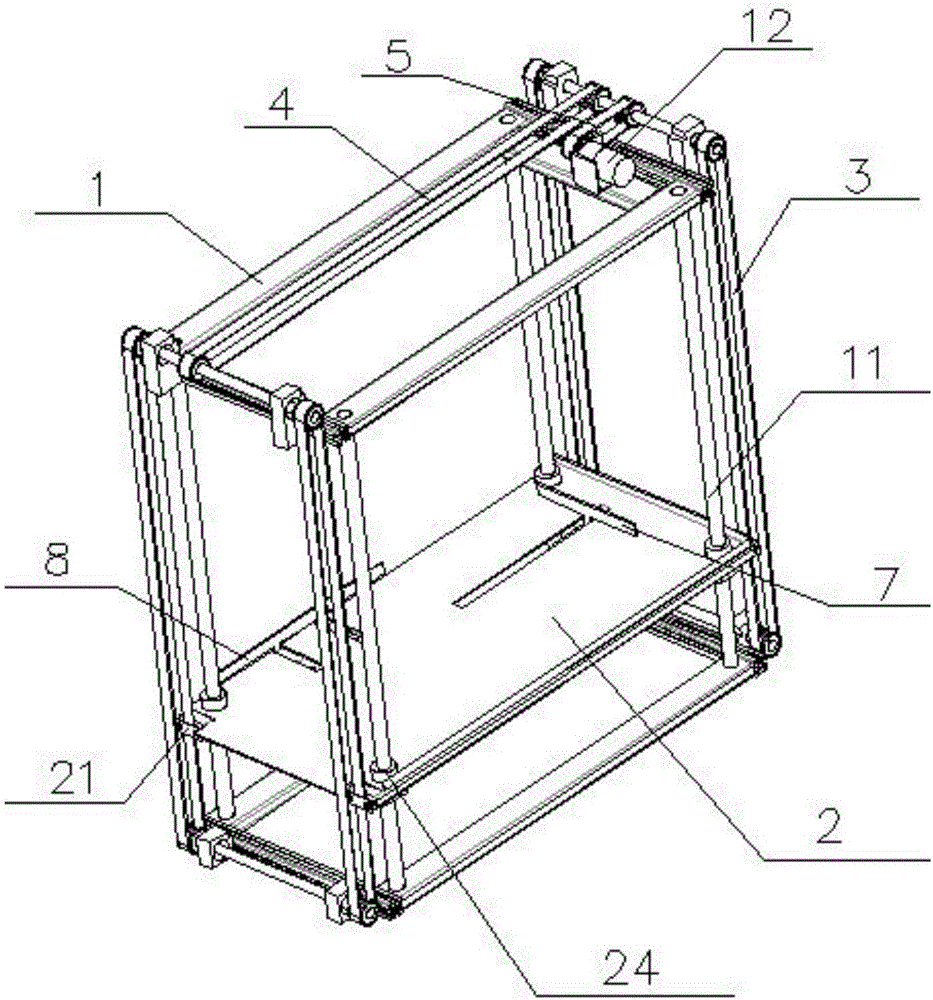

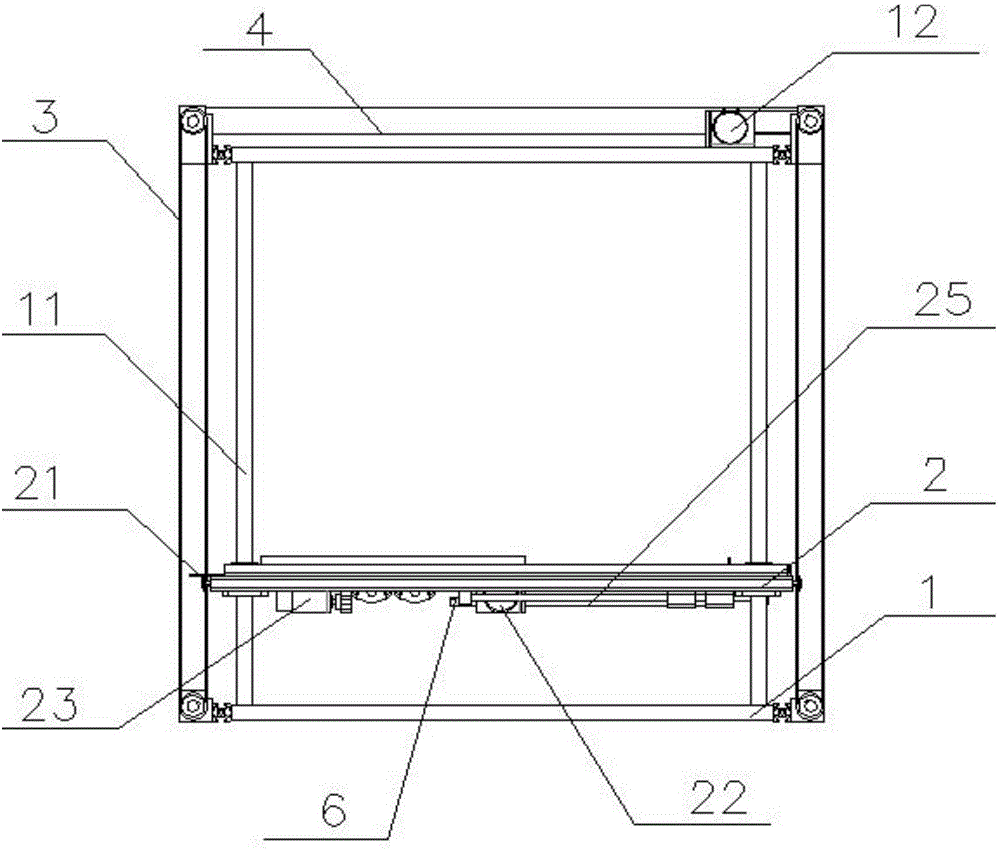

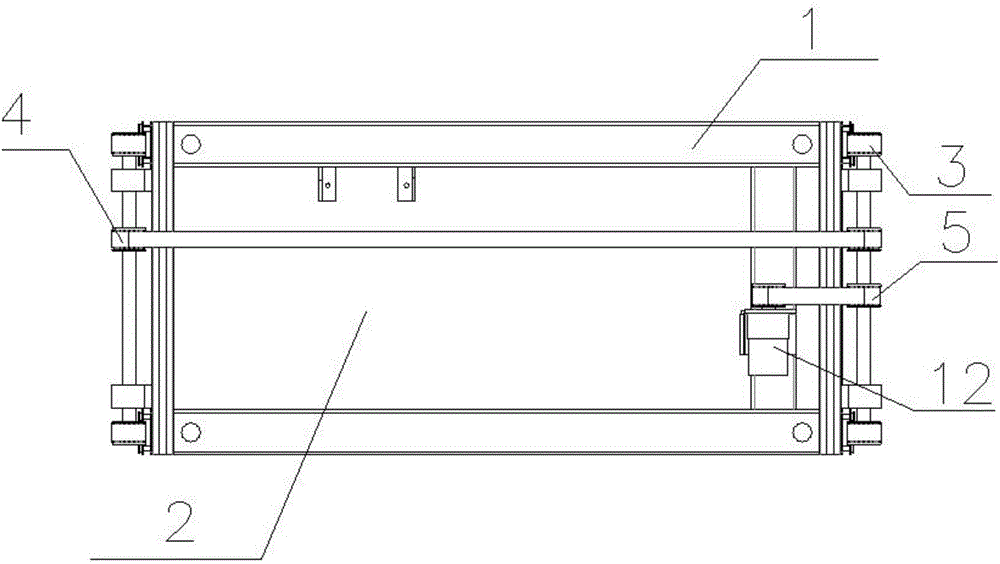

[0026] refer to Figure 1 to Figure 9 , an automatic lifting and translation device for a clean vegetable box of the present invention, comprising a support 1, a connecting plate 2, a front pusher 7, and a side pusher 8, the support 1 is provided with a plurality of slide rails 11 and transmission shafts, and the upper end of the support 1 in the horizontal direction The two transmission shafts are connected with the main synchronous belt 4, and the two transmission shafts in the vertical direction of the support 1 are connected with a number of auxiliary synchronous belts 3. The upper end of the support 1 is equipped with a driving motor 12, the driving motor 12 and the transmission shaft Connect with drive synchronous belt 5 between, described bracket 1 is equipped with connecting plate 2, is provided with slide rail installation sleeve 24 around described connecting plate 2, connects with screw fixing plate 21 between connecting plate 2 and auxiliary synchronous belt 3, The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com