High-speed servo motor side pushing mechanism of intelligent box supply assembly line and side pushing method

A servo motor and assembly line technology, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of reducing the efficiency of workpiece conveying, and it is difficult to ensure the stable conveying of workpieces, etc., and achieve the effect of smooth pushing and improving pushing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

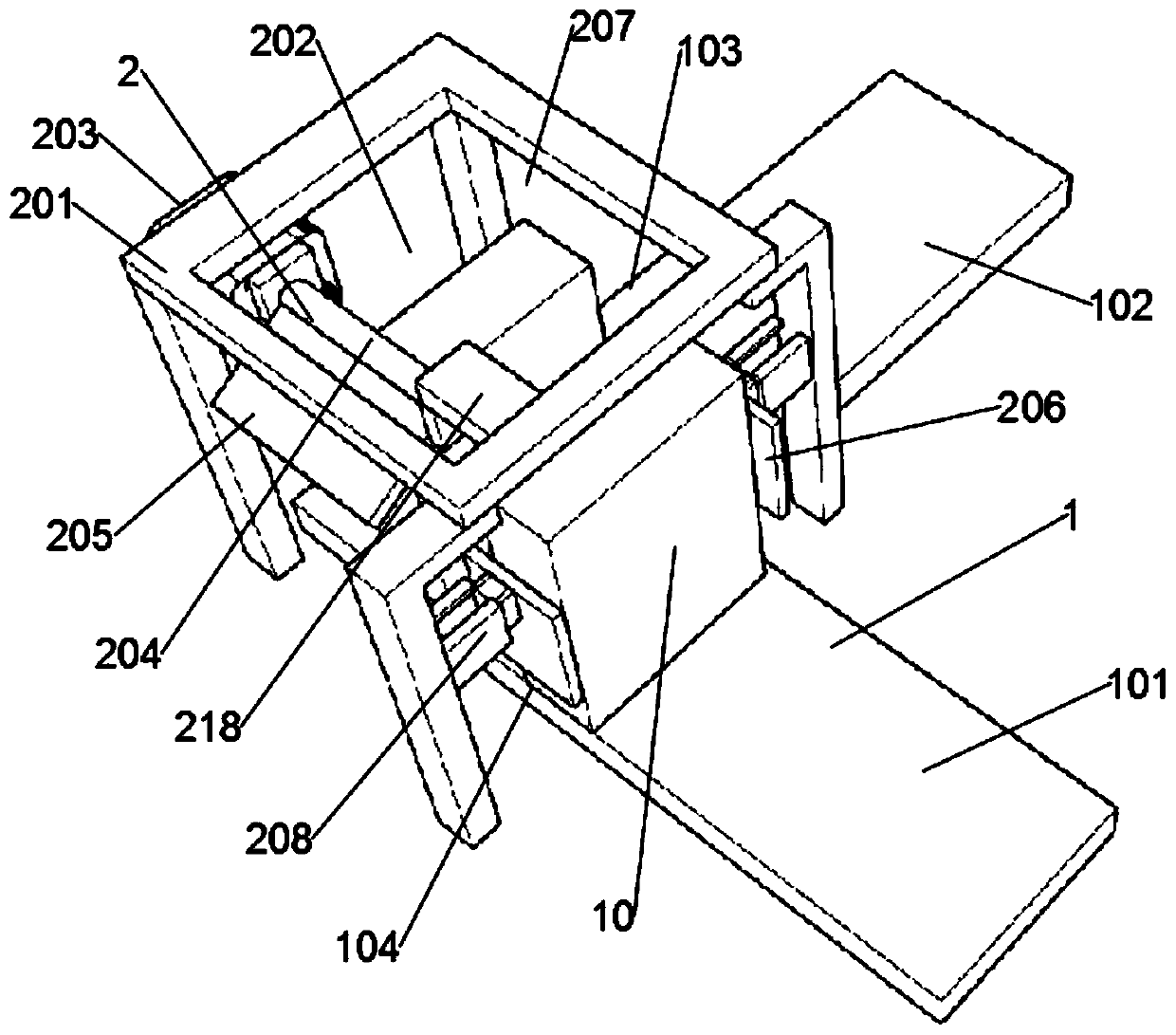

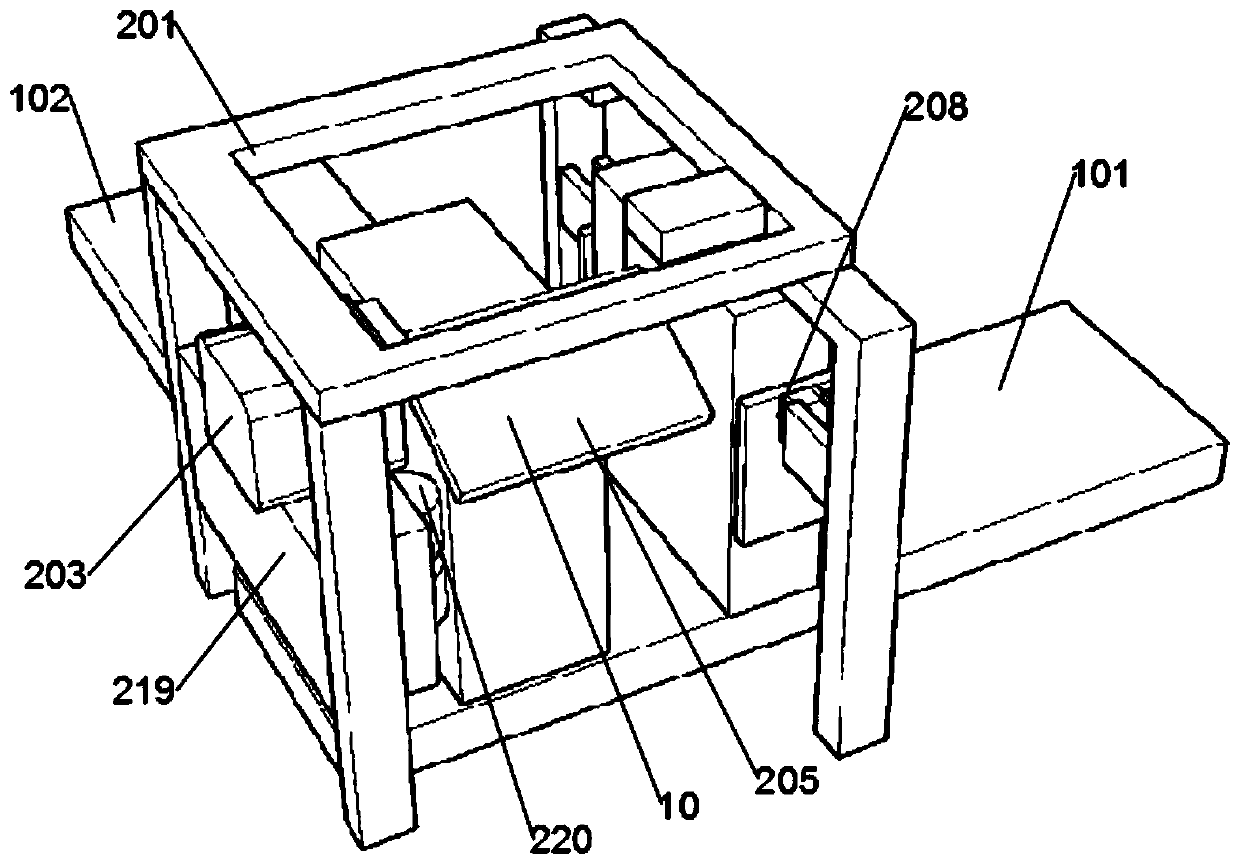

[0035] Such as Figure 1 to Figure 4 As shown, the present invention provides a high-speed servo motor side pushing mechanism of an intelligent box feeding assembly line, aiming to provide a side pushing device for a box-shaped workpiece 10 that can be transported and turned smoothly. specific:

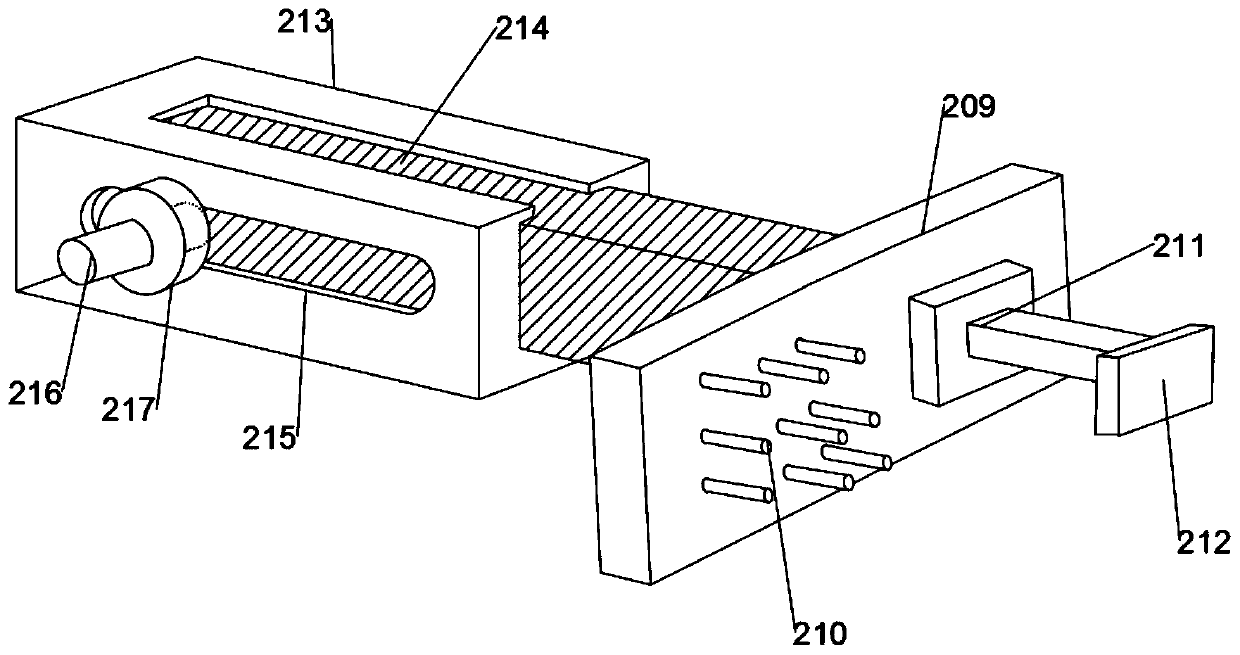

[0036] The side pushing device includes a conveying mechanism 1 and a material pushing mechanism 2 . The conveying mechanism 1 includes two mutually perpendicular first conveying belts 101 and second conveying belts 102 . The conveying starting end 103 of the second conveying belt 102 is arranged on one side of the conveying end 104 of the first conveying belt 101 . It is ensured that the box-shaped workpiece 10 delivered to the delivery end 104 of the first conveyor belt 101 can enter the second conveyor belt 102 and continue to be delivered after being pushed by the pushing mechanism 2 . The pushing mechanism 2 is used to vertically push the box-shaped workpiece 10 transported on...

Embodiment 2

[0052] Such as Figure 5 As shown, a side pushing method of a high-speed servo motor side pushing mechanism of an intelligent box supply assembly line includes the following steps:

[0053] S100, the first conveyor belt transmission: the first conveyor belt transmission transmits the boxed workpiece located in the front to the right below the side push station and limits the position, and uses the clamping device to intercept the boxed workpiece located in the rear;

[0054] S200, side pushing: use the flipping side pushing plate to flip one circle to vertically push the box-shaped workpieces located under the side pushing station on the first conveyor belt to the second conveyor belt one by one;

[0055] S300, second conveyor belt transmission: the workpiece is transmitted on the second conveyor belt, and the clamping device releases the clamped boxed workpiece at the rear, and transfers the released boxed workpiece to the side push station for lowering A side push.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com