Prefabricated assembly type component steel bar positioner

A prefabricated assembly and locator technology, which is applied in the construction field, can solve the problems of insecure connection between the template and the steel structure, the hole plug is not easy to install, and the connection is difficult, so as to achieve the effect of convenient bundling, easy disassembly and fixation, and less workload.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

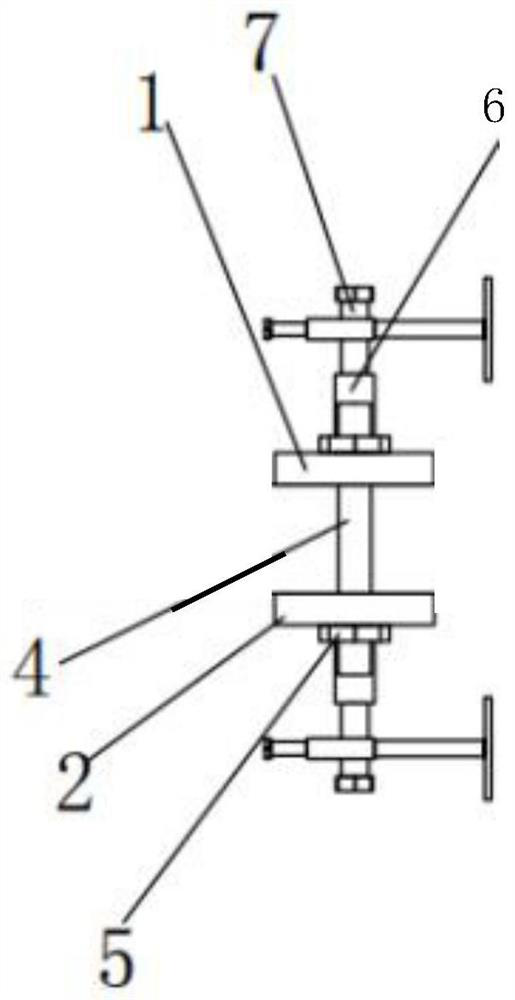

[0022] The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention.

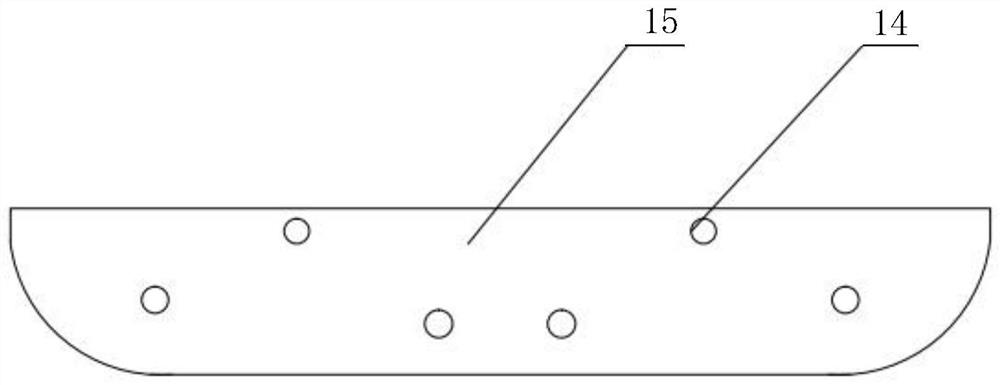

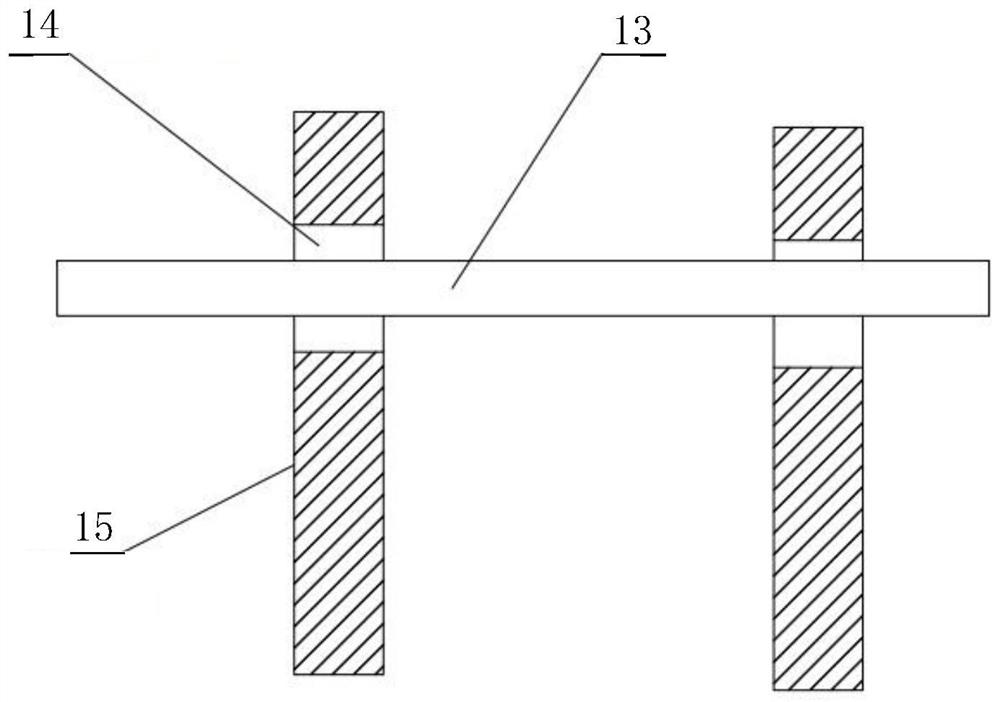

[0023] see image 3 , Figure 4 , a prefabricated component steel bar locator, the key technology of which is to include an upper clamp plate 1, a lower clamp plate 2, a lead screw 7 and a rotating sleeve 9; the left and right sides between the upper clamp plate 1 and the lower clamp plate 2 are respectively installed. The tightening screw 4 and the right clamping screw 3, the center position of the upper surface of the upper clamp plate 1 and the center position of the lower surface of the lower clamp plate 2 are fixed with a guide thread sleeve 6, and the guide thread sleeve 6 and the plate surface to which it is fixedly connected are mutually connected. Vertically, the lead screw 7 is screwed into the inner cavity of the guide threaded sleeve 6, and the lead screw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com