Wastewater recycling system

A waste water recovery and water tank technology, applied to locomotives, etc., can solve the problems of waste of water resources on trains, water shortage, and extended water intervals on trains, and achieve the effects of reducing the water burden of trains, convenient operation and use, and saving train water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

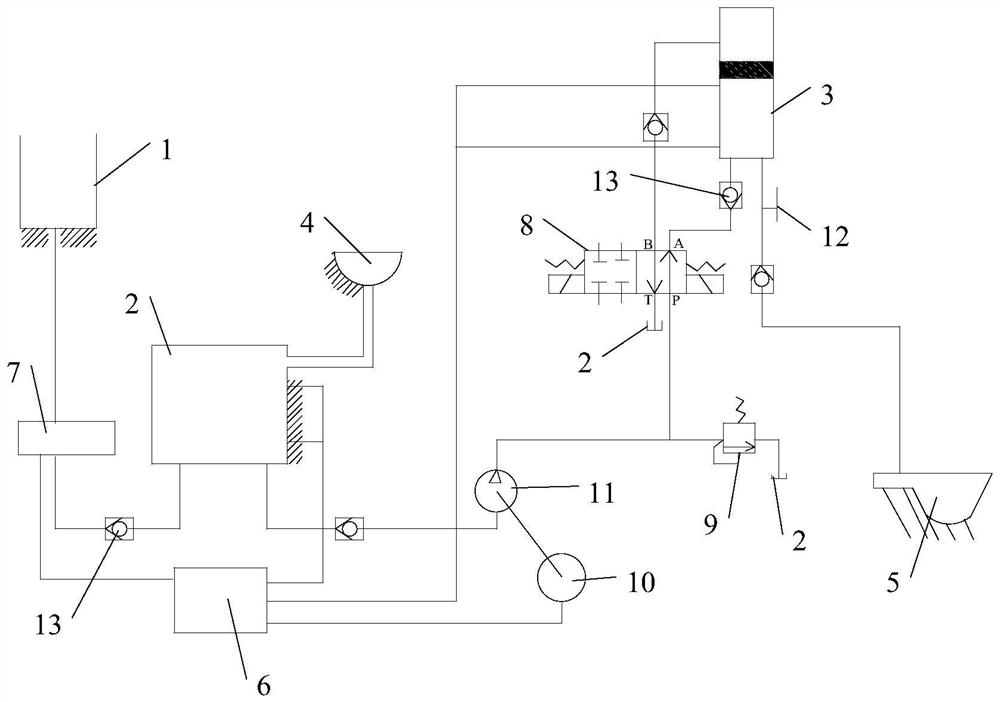

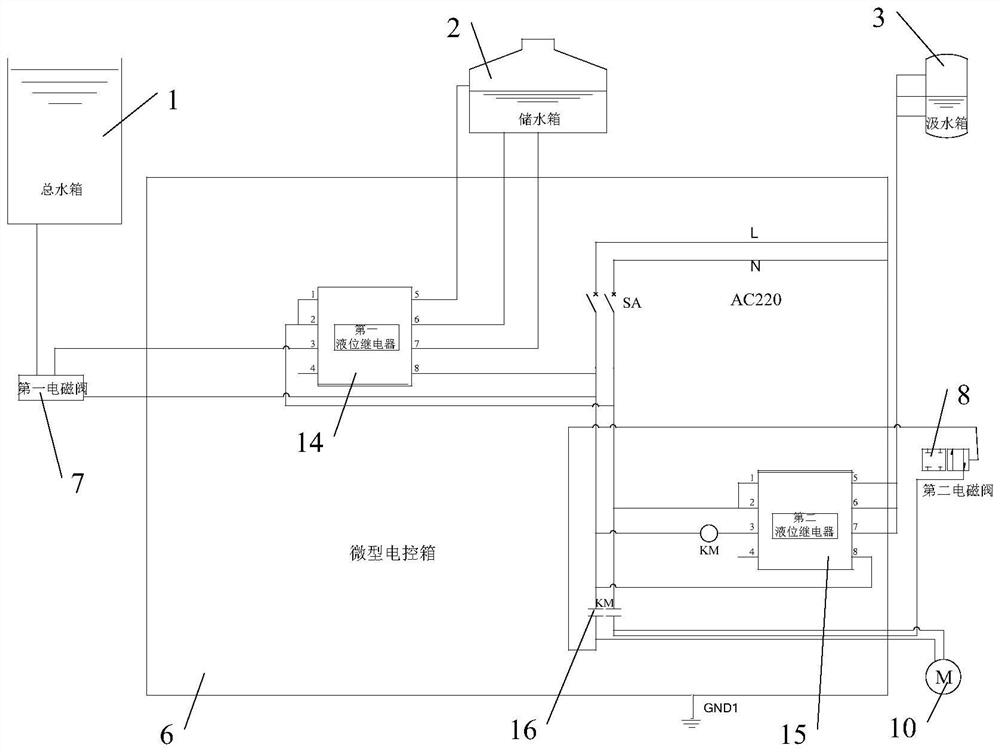

[0025] Various embodiments of the present invention will be described in more detail below with reference to the accompanying drawings. In the various figures, the same elements are designated by the same or similar reference numerals. For the sake of clarity, various parts in the figures are not drawn to scale.

[0026] see figure 1 , The present invention provides a waste water recycling system, the waste water recycling system includes a main water tank 1, a water storage tank 2, a wash basin 4, a water drawing tank 3, a toilet 5, a water pump device and a water replenishment control device. Wherein, the main water tank 1, the wash basin 4 and the water drawing tank 3 are all located above the water storage tank 2, and are connected with the water storage tank 2 through pipelines; the toilet 5 is located below the water drawing tank 3, and is connected with the water storage tank 2. The water-drawing tank 3 is communicated through pipelines; the pipeline between the main ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com