Water drainage pipeline sludge organic and inorganic component on-line separation carbon source extraction system and method

A technology of inorganic components and drainage pipes, applied in separation methods, water/sludge/sewage treatment, water pollutants, etc., can solve the problem of difficult land selection for centralized sludge treatment stations, large transportation workload, and non-point source pollution. and other problems, to achieve the effect of high utilization rate of sludge resources, improvement of filtration flux, and reduction of carbon emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

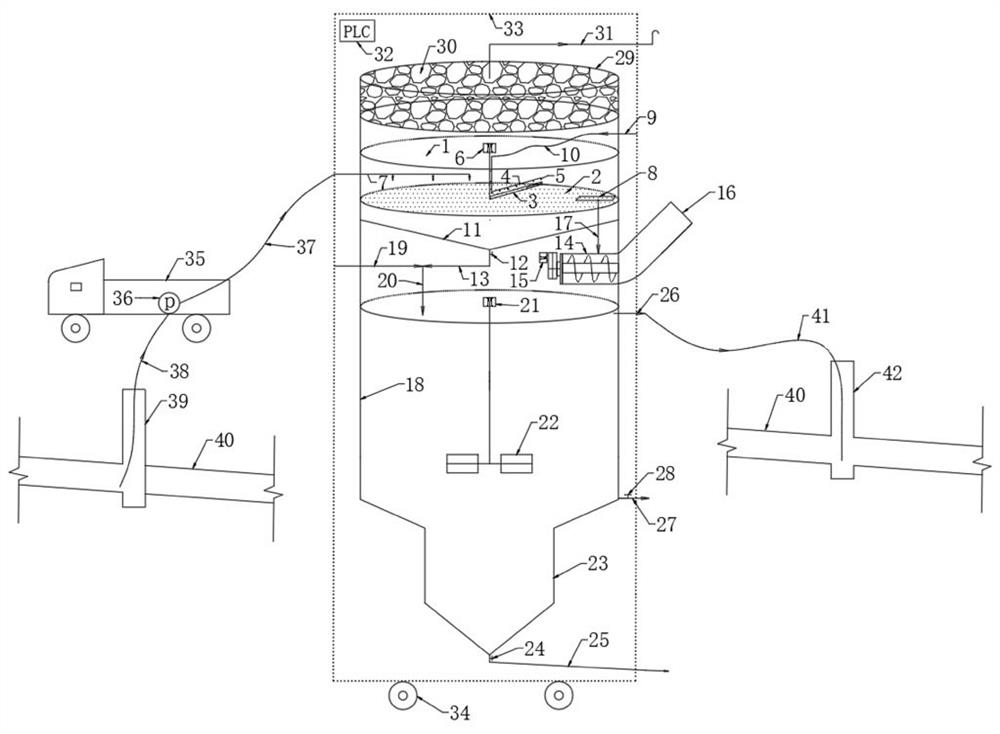

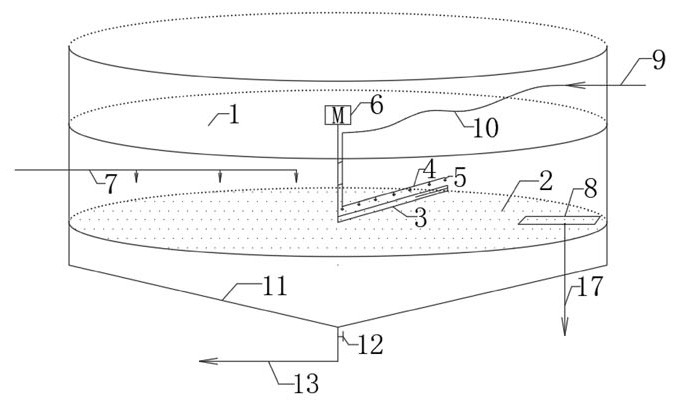

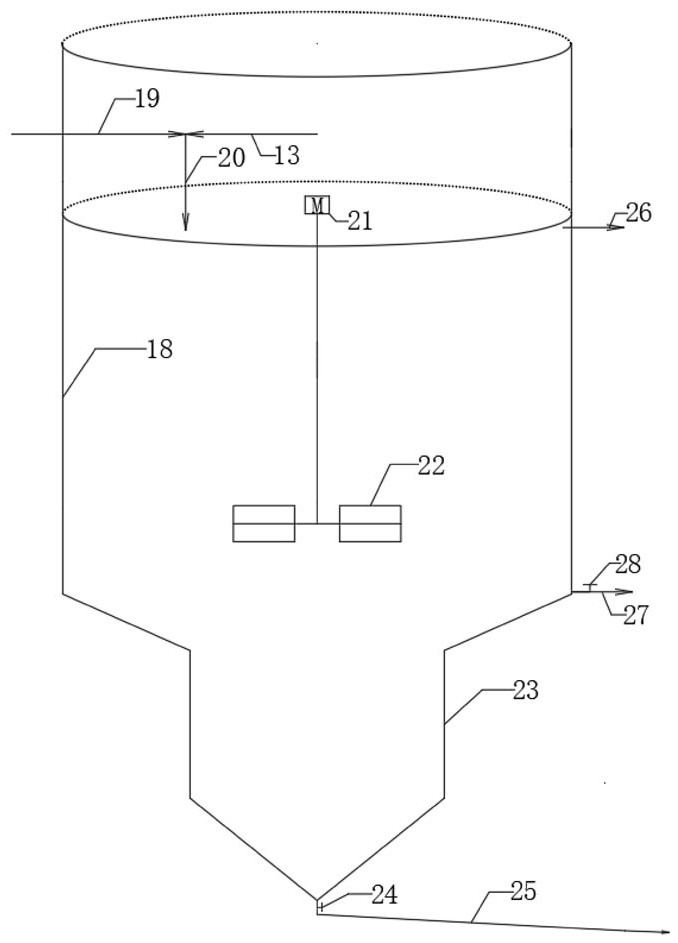

[0078] A method for extracting carbon source by on-line separation of organic and inorganic components of drainage pipeline sludge, utilizing the above-mentioned system for on-line separation of carbon source extraction from organic and inorganic components of drainage pipeline sludge for extraction, comprising the following steps:

[0079] a. Use the suction pump 36 of the sludge cleaning vehicle 35 in the drainage pipe network to pump the dredged sludge in the drainage pipe network to the mud distribution pipe 7 of the pre-treatment module 1 through the suction pipe 38 and the pressure mud pipe 37 In the middle, under the continuous push of the rotating scraper 3 with a height of 4cm, the mud distribution pipe 7 distributes the mud on the surface of the screen grid 2, and most of the sludge quickly passes through the horizontally arranged circular screen under the action of gravity. The circular mesh with an inner diameter of 3 mm of the grid 2 enters the conical rectifying m...

Embodiment 2

[0085] A method for on-line separation of carbon source extraction from organic and inorganic components of sludge in a drainage pipeline, comprising the following steps:

[0086] a. Use the suction pump 36 of the drainage pipe network sludge cleaning vehicle 35 to pump the dredged sludge in the drainage pipe network 40 to the sludge distribution pipe of the pre-treatment module 1 through the sludge suction pipe 38 and the pressure sludge discharge pipe 37 7. Under the continuous push of the rotating scraper 3 with a height of 4cm, the mud distribution pipe 7 distributes mud on the surface of the fixed circular mesh grille 2, and most of the mud quickly passes through the horizontally arranged circle under the action of gravity. The circular mesh holes with an inner diameter of 2 mm of the mesh mesh grid 2 enter the conical rectifying mud hopper 11 at the lower part of the mesh plate grid 2, and at the same time the large-sized particles in the dredging sludge are trapped on th...

Embodiment 3

[0092] A method for on-line separation of carbon source extraction from organic and inorganic components of sludge in a drainage pipeline, comprising the following steps:

[0093] a. Use the suction pump 36 of the drainage pipe network sludge cleaning vehicle 35 to pump the dredged sludge in the drainage pipe network 40 to the sludge distribution pipe of the pre-treatment module 1 through the sludge suction pipe 38 and the pressure sludge discharge pipe 37 7. Under the continuous push of the rotating scraper 3 with a height of 4cm, the mud distribution pipe 7 distributes mud on the surface of the fixed circular mesh grille 2, and most of the mud quickly passes through the horizontally arranged circle under the action of gravity. The circular mesh holes with an inner diameter of 2.5 mm of the mesh mesh grid 2 enter the conical rectifying mud hopper 11 at the lower part of the mesh plate grid 2, and at the same time, the large-sized particles in the dredging sludge are trapped on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com