Porous rotary-cut valve achieving pairwise intercommunication

A rotary cutting valve and valve head technology, which is applied in the direction of multi-way valves, valve details, valve devices, etc., can solve the problems of single connection state and the inability to connect the ports of the rotary cutting valve, so as to simplify the flow system and ensure Accuracy, the effect of improving experimental efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

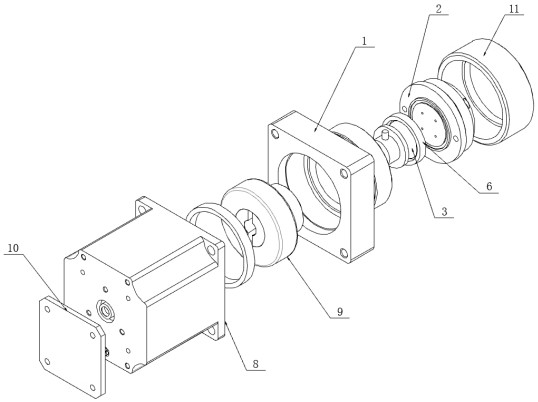

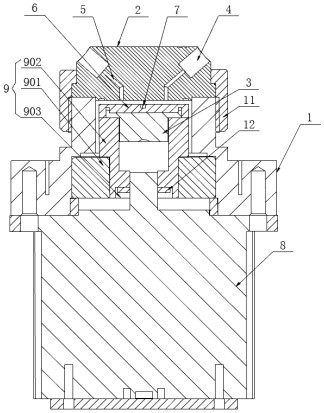

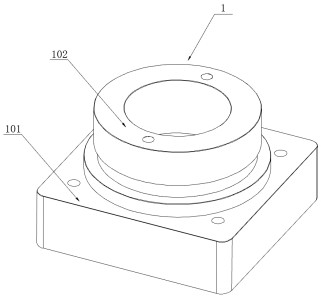

[0036] like figure 1 As shown in the figure, the present invention provides a multi-hole rotary cut valve for realizing two-to-two communication, which includes a valve body fixing seat 1, the top of the valve body fixing seat 1 is fixedly provided with a porous rotary cutting valve head 2, and the valve body fixing seat 1 A rotating core 3 is arranged in the internal rotation;

[0037] The valve head 2 of the multi-hole rotary cut valve is provided with a plurality of hole positions 4, and the plurality of hole positions 4 are evenly distributed on the same circle with the center of the multi-hole rotary valve head 2 as the center, and each hole position 4 is matched with a channel. 5. Each channel 5 runs through the bottom end face of the valve head 2 of the porous rotary valve;

[0038] The rotary core 3 is fixedly provided with a rotary cutting valve sheet 6, and the upper end face of the rotary cutting valve sheet 6 is in mirror contact with the bottom end face of the mu...

Embodiment 2

[0040] like Figure 1~Figure 3 As shown, this embodiment is further limited on the basis of Embodiment 1. The multi-hole rotary cut valve that realizes the communication between two in the present invention also includes a driving member for driving the rotating core 3 to rotate around its own axis, and the driving member includes a step The input motor 8 is provided with a mechanical transmission member 9 on the output shaft of the stepping motor 8, and the mechanical transmission member 9 is fixedly connected with the rotating core 3 through the valve body fixing seat 1; the stepping motor 8 is provided with a control step motor 8 to rotate Angle controller 10. The rotation angle of the stepping motor is controlled by the controller 10, and the output shaft of the stepping motor 8 drives the rotating core 3 to rotate through the mechanical transmission member 9, thereby realizing that the plurality of channels 7 on the rotary cutting valve plate 6 are in different states.

...

Embodiment 3

[0045] like Figure 1~Figure 4 As shown, this embodiment is further limited on the basis of Embodiment 2. As a specific setting method of the valve head 2 of the multi-hole rotary cutting valve, the valve head 2 of the multi-hole rotary cutting valve is provided with 4 holes 4 and 4 holes. The hole positions 4 are evenly distributed on the same circle with the center of the valve head 2 of the multi-hole rotary cut valve as the center of the circle. For ease of understanding, four letters A, B, C, and D are set on the surface of the valve head 2 of the multi-hole rotary cut valve, which correspond to four hole positions 4 respectively. In this embodiment, the four hole positions 4 are referred to as A hole positions , B hole position, C hole position and D hole position.

[0046] The rotary valve plate 6 is provided with a first channel 13 and a second channel 14, the first channel 13 is a linear structure, the first channel 13 passes through the center of the rotary valve pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com