Cooling triangular unit with rotating plate type flow-equalizing and anti-freezing integrated device

A technology of cooling triangles and rotating plates, which is applied in the direction of fixed duct components, lighting and heating equipment, indirect heat exchangers, etc., and can solve problems such as uneven air intake of cooling triangle units and low surface temperature of cooling columns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

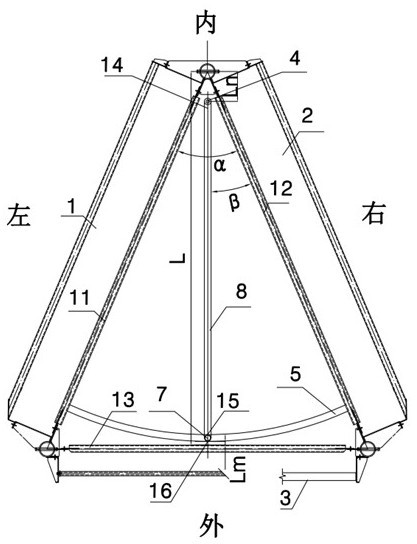

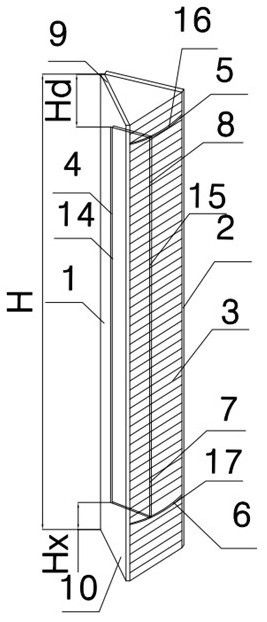

[0024] Embodiment 1 is a cooling triangular unit with a rotating plate-type flow-equalizing and anti-freezing integrated device in summer.

[0025] like image 3 As shown, a cooling triangular unit with a rotating plate-type flow-equalizing and anti-freezing integrated device of the present invention includes a cooling triangle unit and a rotating-plate type flow-equalizing and anti-freezing integrated device. The cooling triangle unit includes a left cooling column 1, a right cooling column 2 and an air inlet shutter 3, and the rotating plate type flow equalization and antifreeze integrated device includes a vertical rotating shaft 4, an upper arc slide 5, a lower arc slide 6, a vertical Move the shaft 7 and the rotating plate 8 straight. In the cooling triangle unit, the horizontal and vertical distance from the intersection of the left cooling column support surface 11 and the right cooling column support surface 12 to the air inlet louver support surface 13 is 3m, and the...

Embodiment 2

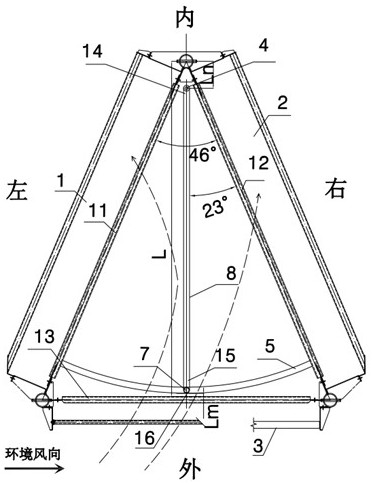

[0026] Example 2 is a cooling triangular unit with a rotating plate-type flow-equalizing and antifreezing integrated device when ambient air enters from the left side of the cooling triangular unit in winter.

[0027] like Figure 4 As shown, a cooling triangular unit with a rotating plate-type flow-equalizing and anti-freezing integrated device of the present invention includes a cooling triangle unit and a rotating-plate type flow-equalizing and anti-freezing integrated device. The cooling triangle unit includes a left cooling column 1, a right cooling column 2 and an air inlet shutter 3, and the rotating plate type flow equalization and antifreeze integrated device includes a vertical rotating shaft 4, an upper arc slide 5, a lower arc slide 6, a vertical Move the shaft 7 and the rotating plate 8 straight. In the cooling triangle unit, the horizontal and vertical distance from the intersection of the left cooling column support surface 11 and the right cooling column suppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com