High-speed train wheel diameter dynamic detection method based on laser measurement

A train wheel, dynamic detection technology, applied in the field of traffic safety engineering, can solve the problems of difficult installation work and inability to analyze the visual measurement method calibration, and achieve the effects of satisfying detection accuracy, low installation location requirements, and simple calibration method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

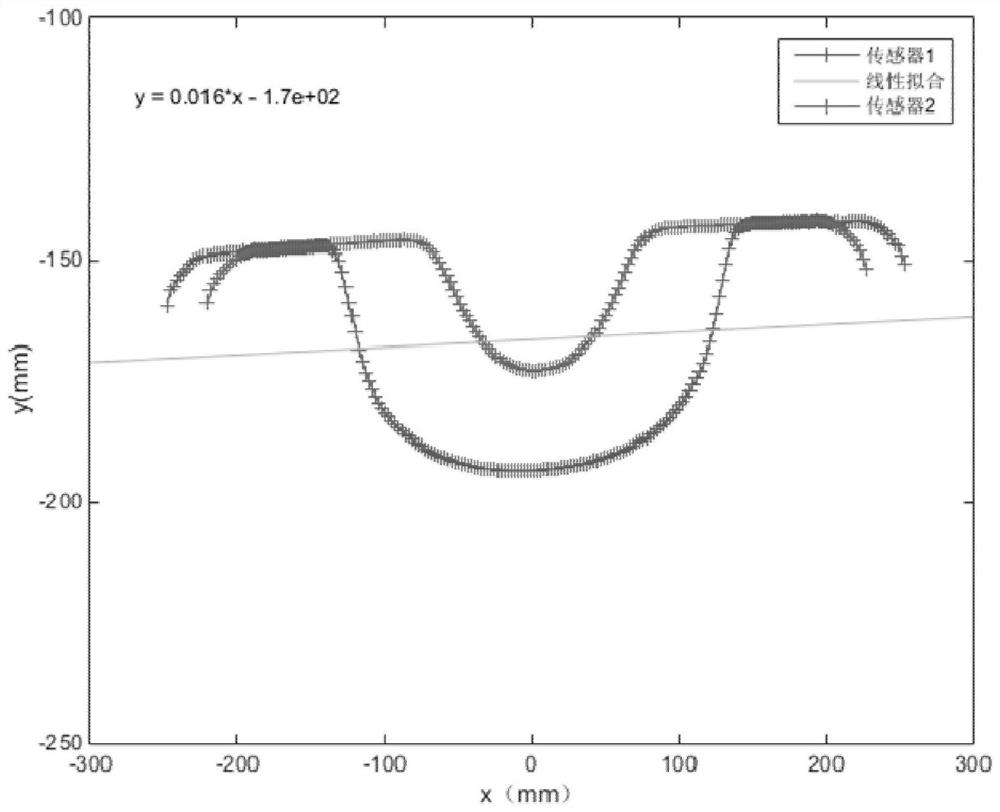

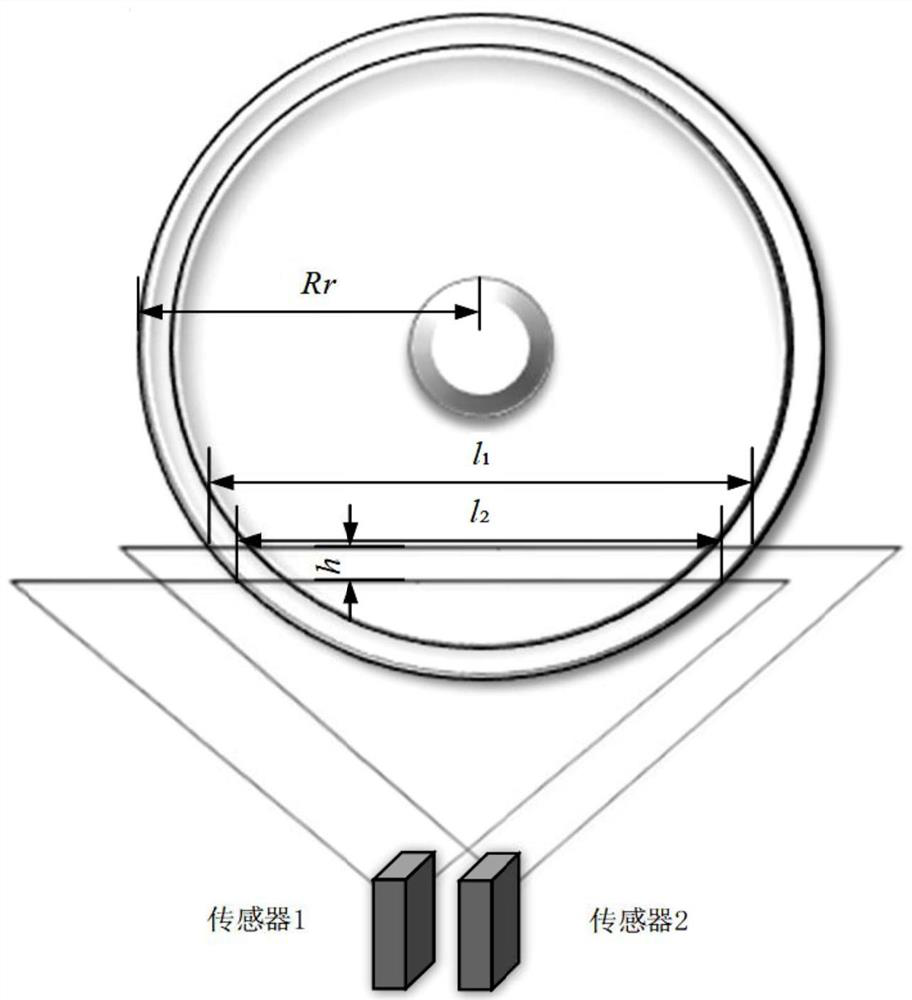

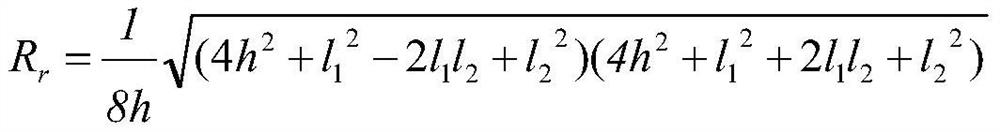

[0054] In the present embodiment, a method for dynamically detecting the diameter of a high-speed train wheel based on laser measurement includes the following steps:

[0055] Step 1: Determine the installation position and angle of the two laser sensors for measuring wheel diameter, and calibrate their spatial positions. The process is as follows:

[0056] Install the two laser sensors for measuring the wheel diameter on the inner side of the rail closer to the rail, 120cm horizontally away from the other side of the rail and 30mm below the rail plane, so that the irradiation plane of the two laser sensors is parallel to the rail, and the two laser irradiation planes are staggered up and down They are separated by 20mm and parallel to each other, and the included angle between the laser irradiation plane and the plane of the rail is 6°.

[0057] Two standard blocks are placed on the track, and the two blocks are staggered, parallel to each other, and separated by a certain di...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap