Plastic package integrated circuit batch ultrasonic scanning inspection device and method

A technology for integrated circuits and inspection devices, which can be applied to measurement devices, analysis of solids using sonic/ultrasonic/infrasonic waves, and material analysis using sonic/ultrasonic/infrasonic waves. and other problems, to achieve the effect of improving work efficiency and accuracy, and solving the low efficiency of placing and turning over

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

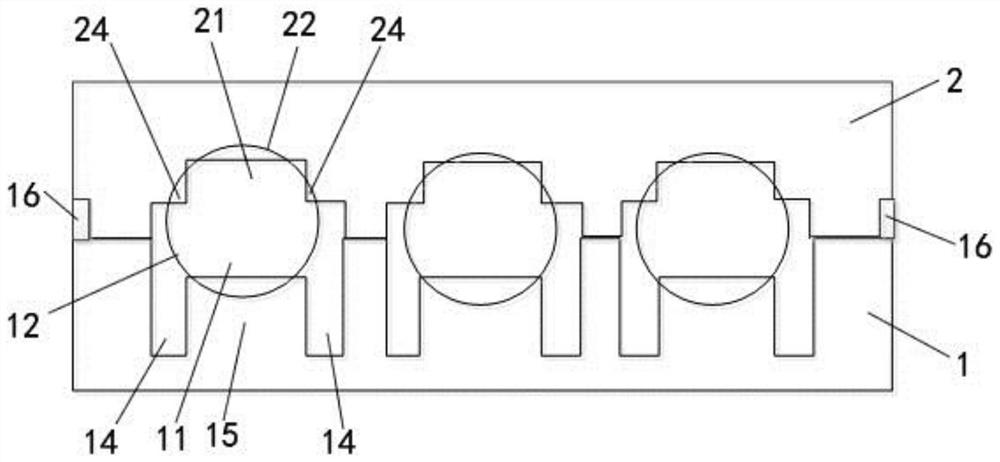

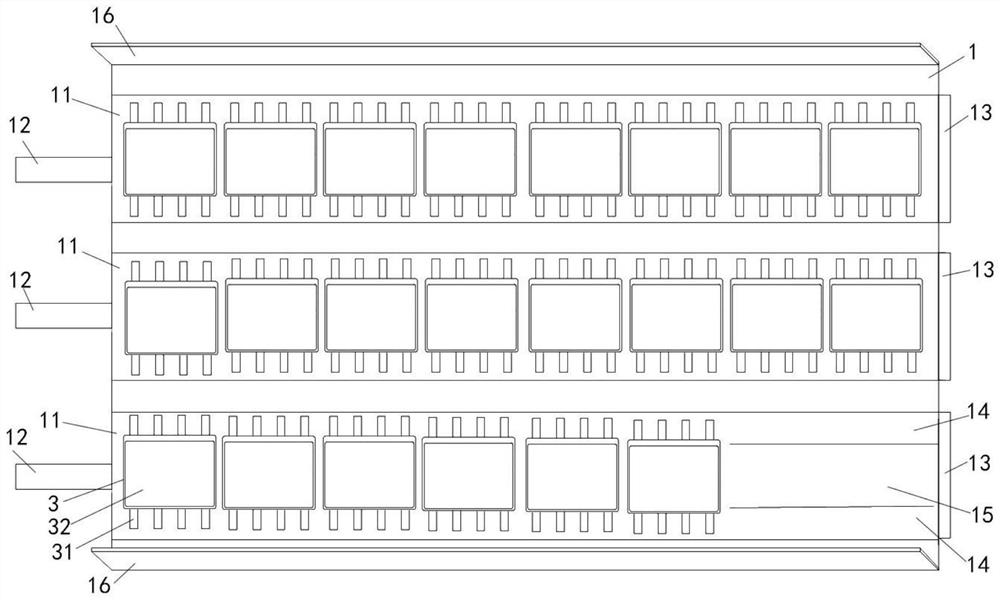

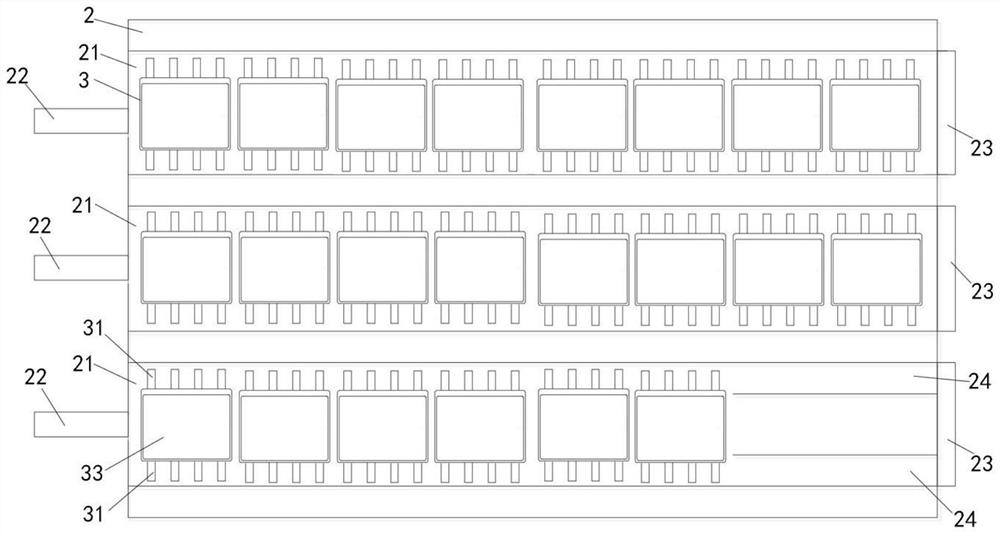

[0041] like Figure 1 to Figure 5As shown, a batch ultrasonic scanning inspection device for plastic-encapsulated integrated circuits in this embodiment includes a first tray 1 and a second tray 2, and the first tray 1 and the second tray 2 are both flat-plate structures; The tray 1 is provided with a plurality of first through grooves 11 penetrating two opposite sides of the first tray 1 . One end of the first through groove 11 is provided with a first air inlet half-pipe 12 ; the second tray 2 There are a plurality of second through grooves 21 penetrating two opposite sides of the second tray 2, and one end of the second through groove 21 is provided with a second air inlet half pipe 22; the second tray 2 can be buckled It is closed on the first tray 1, and the first through groove 11 and the second through groove 21 are enclosed to form a accommodating cavity for accommodating the plastic-encapsulated integrated circuit. The integrated circuit is stably clamped, and the fi...

Embodiment 2

[0064] A method for batch ultrasonic scanning inspection of plastic-encapsulated integrated circuits in this embodiment is implemented by using the batch ultrasonic scanning and inspection device for plastic-encapsulated integrated circuits described in Embodiment 1, and includes the following steps:

[0065]S1 , place the front surface 32 of the plastic-encapsulated integrated circuit 3 upward and continuously into the first through slot 11 of the first tray 1 , and then use the second tray 2 to buckle on the first tray 1 and closely fit the first tray 1 , put the first tray 1 and the second tray 2 into the water tank together, so that the second tray 2 is located above the first tray 1, and the front side 32 of the plastic-encapsulated integrated circuit 3 is arranged upward;

[0066] S2, use an air pump and an air tube to purge the first through groove 11 and the second through groove 21 to form the accommodation cavity for accommodating the plastic-packaged integrated circu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com