Geometric parametric modeling method for meridian aircraft tire

A technology of aviation tires and geometric parameters, applied in geometric CAD, tire parts, reinforcement layers of pneumatic tires, etc., can solve the problems of time-consuming and complex tire geometry drawing, and achieve the effect of promoting ability improvement and shortening research and development cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

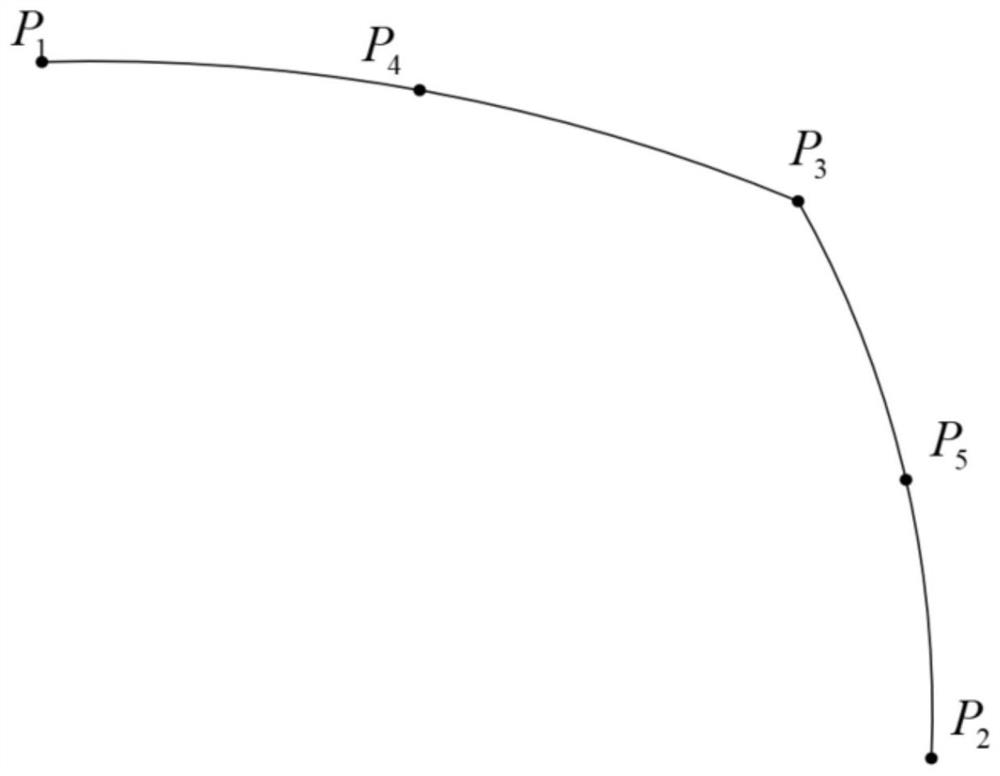

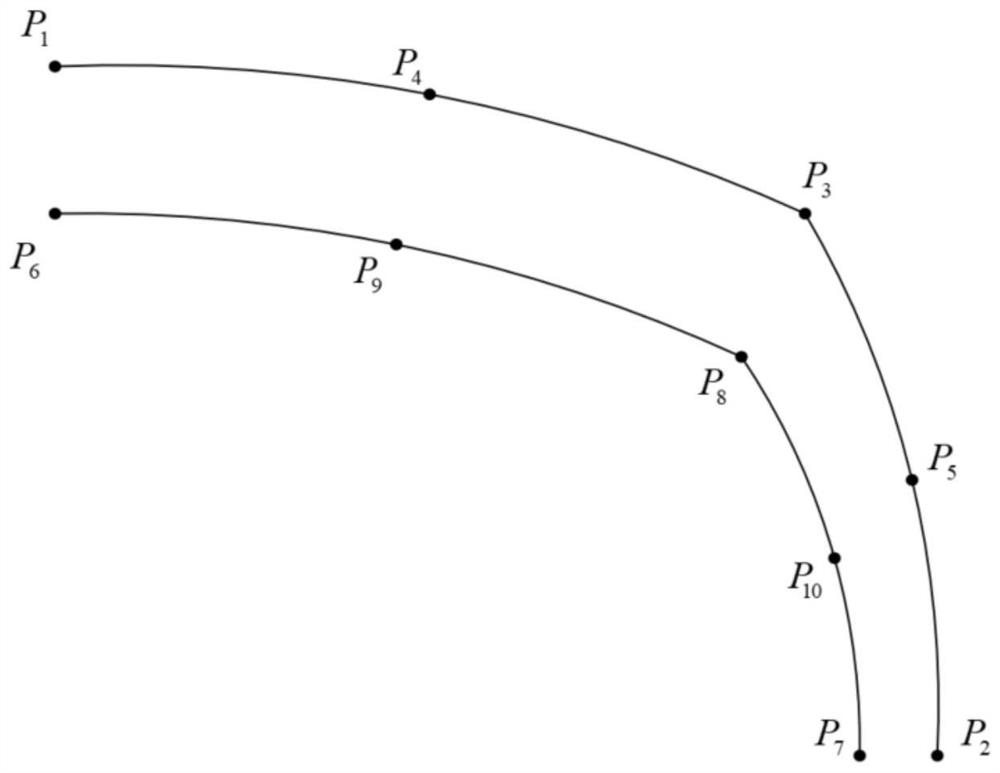

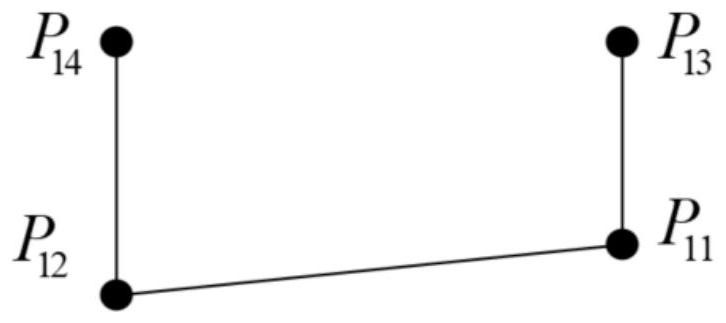

[0020] The present invention realizes above-mentioned technical purpose through the following steps:

[0021] The geometric parametric modeling method of radial aviation tires, the method is: according to the maximum diameter R of the tire vertical 、Maximum width of tire section W max , rim diameter R rim , the thickness of the inner liner T IL , sidewall thickness T SideWall , Bead taper A taper , the ratio of rim width to tire section width W ratio , Tread thickness T tread 、 Lateral thickness T of tire heel HealH , the longitudinal thickness of the tire heel T HealV , Reinforcing layer thickness T PP , diameter of traveler R bead , carcass ply thickness T CP , Belt thickness T BP , the lateral distance D between the vertex of the apex and the center of the traveler circle apexH , the longitudinal distance D between the vertex of the apex and the center of the traveler apexV , to build a 3D model of radial aeronautical tires. According to the above 16 parameter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com