Self-adaptive valve clamping device and valve clamping system

An adaptive valve technology, applied in the direction of the heart valve, can solve the problems affecting the closing of the forceps arm and the damage of the valve leaflet, so as to achieve the effect of axial force balance and avoid damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

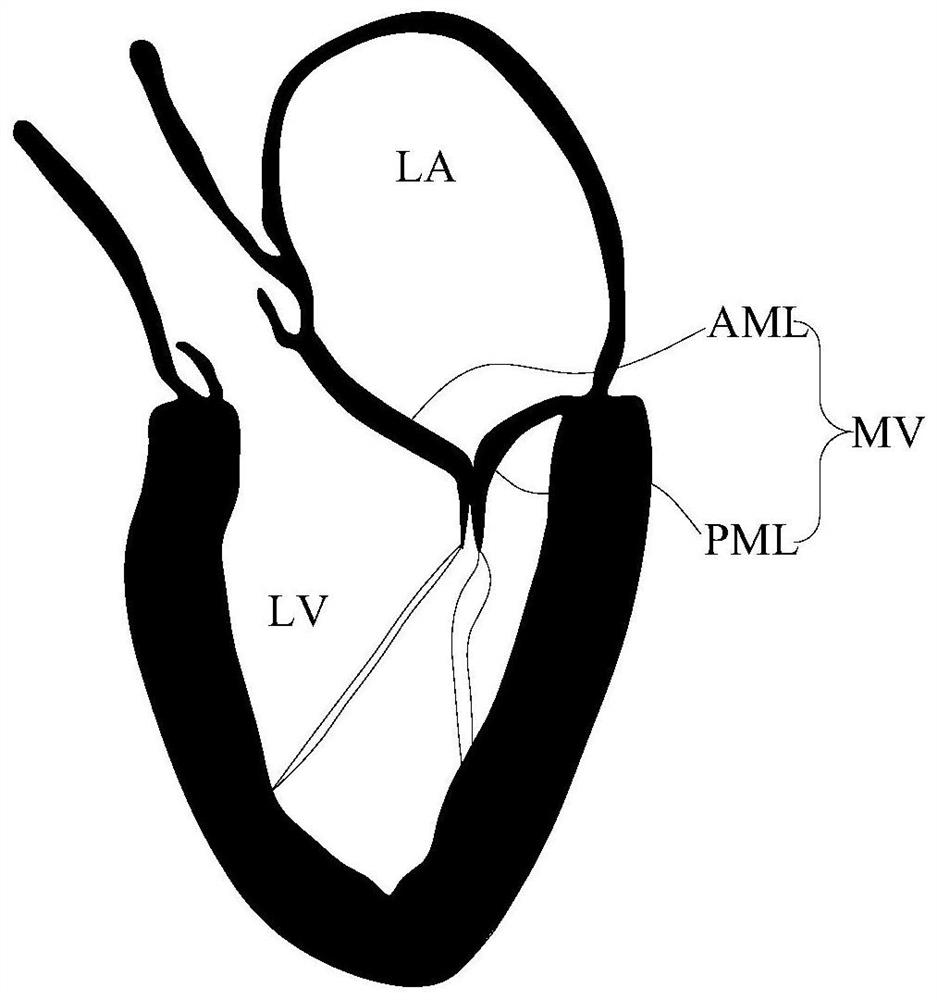

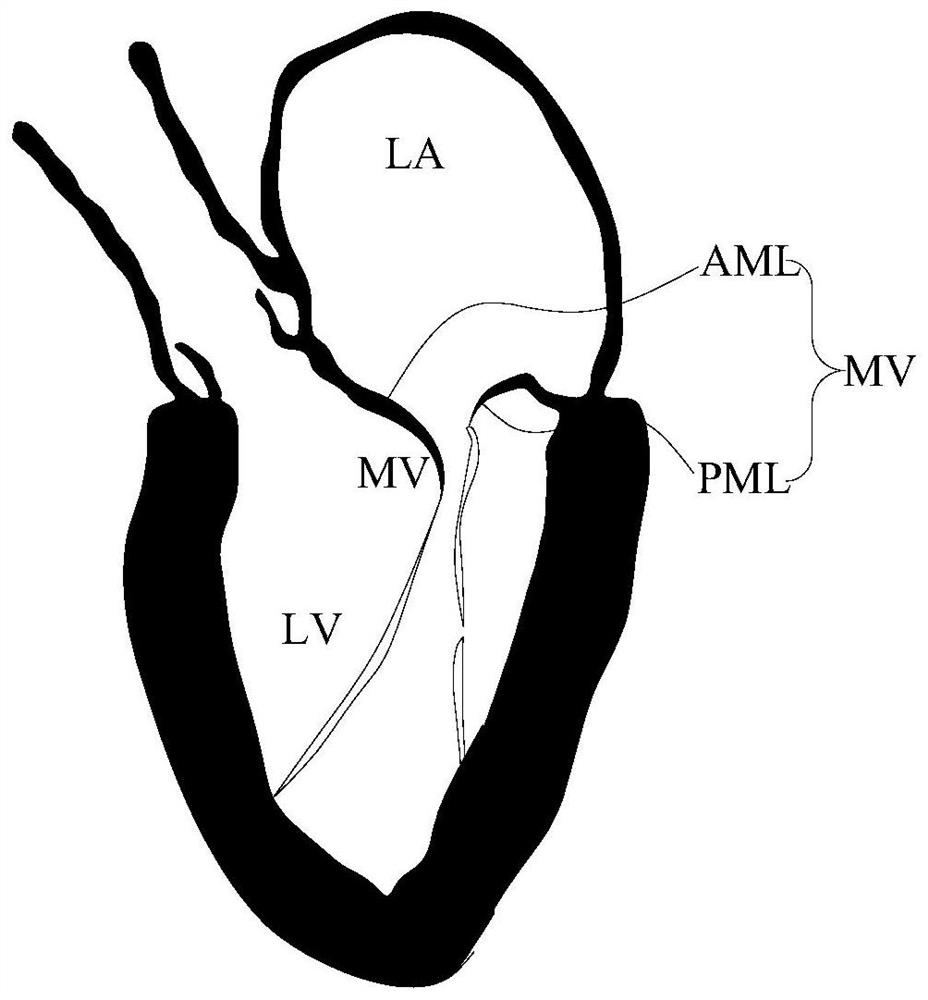

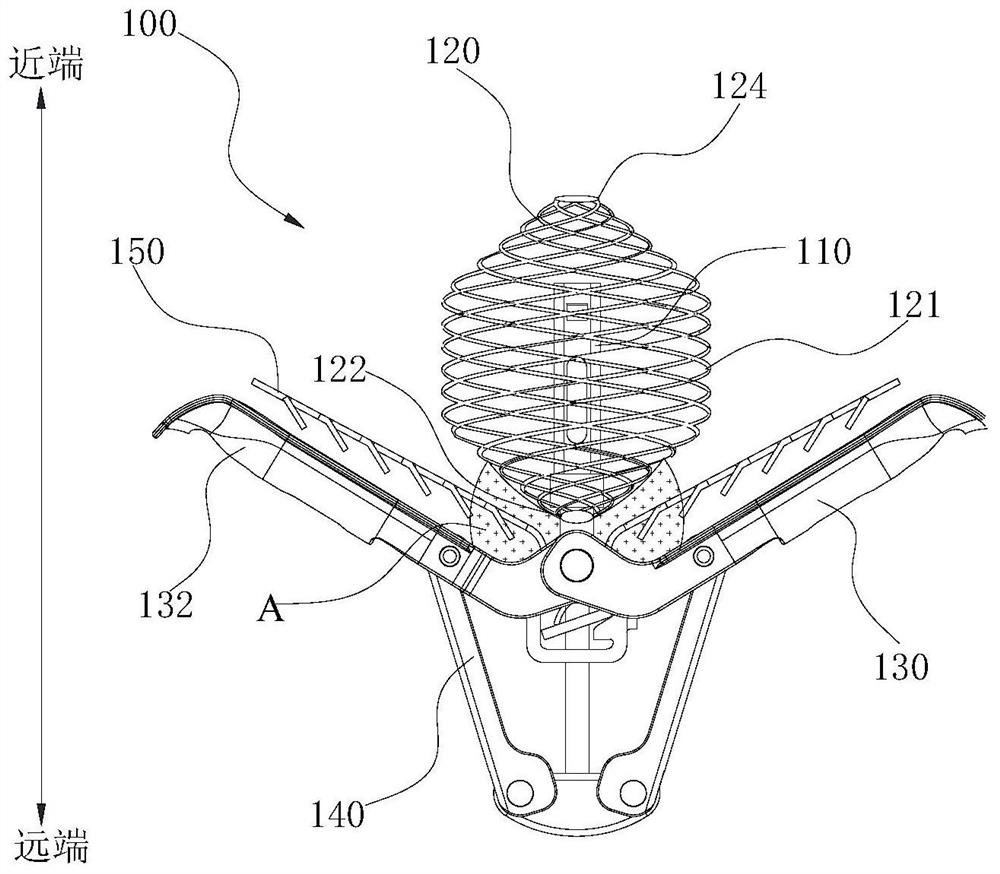

[0044] see Figure 3 to Figure 5 , An adaptive valve clamping device 100 provided in the first embodiment of the present application can be used for edge-to-edge repair of the mitral valve or tricuspid valve to treat mitral valve regurgitation or tricuspid valve regurgitation. In order to ensure the safety of the adaptive valve clamping device 100 after implantation, the adaptive valve clamping device 100 is entirely made of biocompatible materials. The following will take the adaptive valve clamping device 100 for mitral valve edge-to-edge repair as an example for detailed description. The operator uses the delivery device 200 to advance the adaptive valve clamping device 100 to the patient's mitral valve, and then operates the adaptive valve clamping device 100 remotely to clamp the anterior and posterior leaflets of the mitral valve together. When the leaflets of the mitral valve are aligned edge-to-edge, the operator can release the connection between the delivery device ...

Embodiment 2

[0093] see Figure 22-Figure 25 , compared with the adaptive valve clamping device 100 of the first embodiment, the adaptive valve clamping device of the second embodiment of the present application is different in that the first sealing head 426 of the adjusting part 420 and the second seat body 414 of the supporting part 410 The structure is different.

[0094] Specifically, the first head 426 is movably sleeved on the outer side of the second seat body 414 of the support portion 410 , the inner cavity of the first head 426 is provided with a first anti-rotation member 4260 , and the outer surface of the second seat body 414 corresponds to The first anti-rotation member 4260 is provided with a second anti-rotation member 4140, and the first anti-rotation member 4260 and the second anti-rotation member 4140 are detachably connected to each other. In this way, the adjusting portion 420 is restricted from rotating around the axial direction by arranging the first anti-rotation...

Embodiment 3

[0101] see Figure 26 and Figure 27 , compared with the adaptive valve clamping device of the third embodiment of the present application and the adaptive valve clamping device of the second embodiment, the difference lies in the structure of the first head 526 of the adjustment part 520 and the second seat body 514 of the support part 510 different. In this embodiment, the first head 526 and the first anti-rotation member 5260 are connected separately, and / or, the second base 524 and the second anti-rotation member 5140 are connected separately. Specifically, the first head 526 and the first anti-rotation member 5260 can be fixed together by common detachable or non-detachable connection methods such as welding, bonding, screw connection, crimping, and bolt locking. The second base body 514 and the second anti-rotation member 5140 can be fixed together by common detachable or non-detachable connection methods such as welding, bonding, screw connection, crimping, bolt locki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com