Man-machine interaction system and method based on operator intention correction

A human-computer interaction and operator technology, which is applied in the field of surgical robots, can solve the problems of different rotation intentions of robotic arms, difficulty in installing surgical tools, and poor precision, so as to achieve good human-computer interaction, reduce learning costs, and increase safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

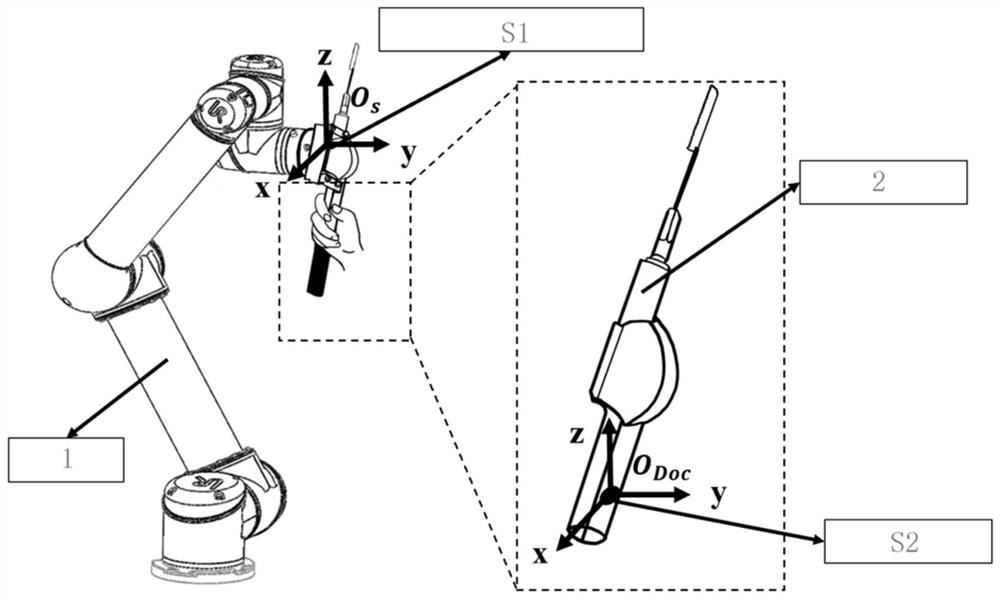

[0043] In a first aspect, the present invention discloses a human-computer interaction system based on operator intention correction, comprising a robotic arm 1, a surgical tool 2, a six-dimensional force sensor S1, a force sensor S2 and a controller;

[0044] like figure 1 As shown, the six-dimensional force sensor S1 is installed on the end of the robotic arm 1, the surgical tool 2 is mounted on the six-dimensional force sensor S1 through the fixing device, the force sensor S2 is mounted on the surgical tool 2, the controller is connected with the robotic arm 1, the six-dimensional force The sensor S1 and the force sensor S2 are connected in communication;

[0045] When the operator pulls the part where the force sensor S2 is installed on the surgical tool 2 to operate, the controller detects whether the reading of the force sensor S2 reaches the preset threshold; if the reading of the force sensor S2 does not reach the preset threshold, the robotic arm 1 does not move, Oth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com