Dedusting, denitration and desulfurization integrated system

A desulfurization system and denitrification technology, applied in the field of dust removal, desulfurization integrated system, and denitrification, can solve the problem that flue gas cannot meet the environmental protection emission requirements of pollutants in key areas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The specific embodiments of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments. The following examples are intended to illustrate the present invention, but not to limit the scope of the present invention.

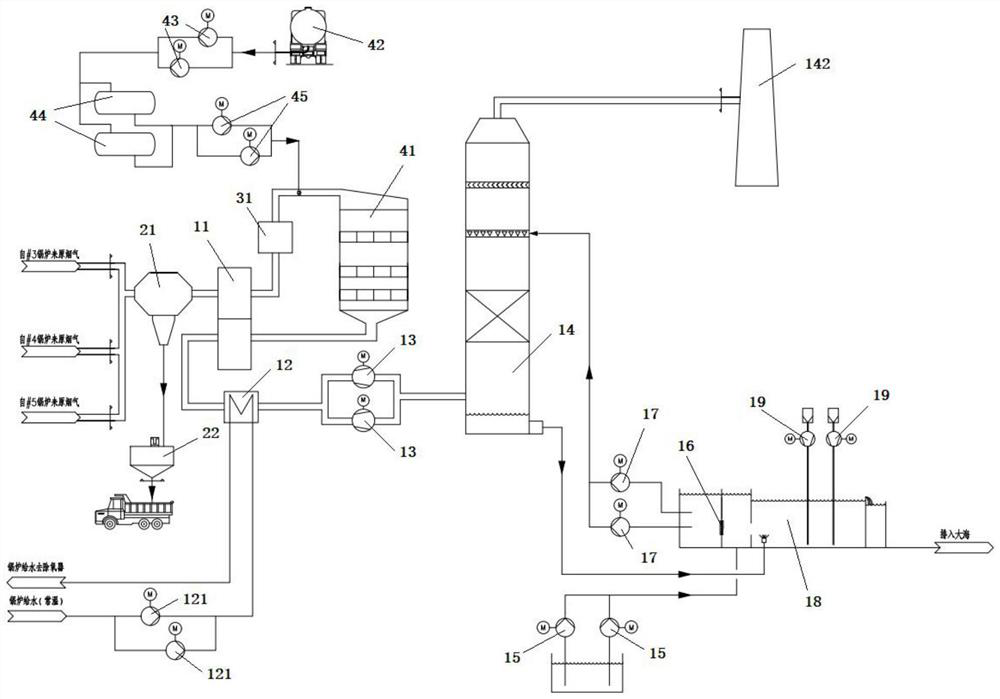

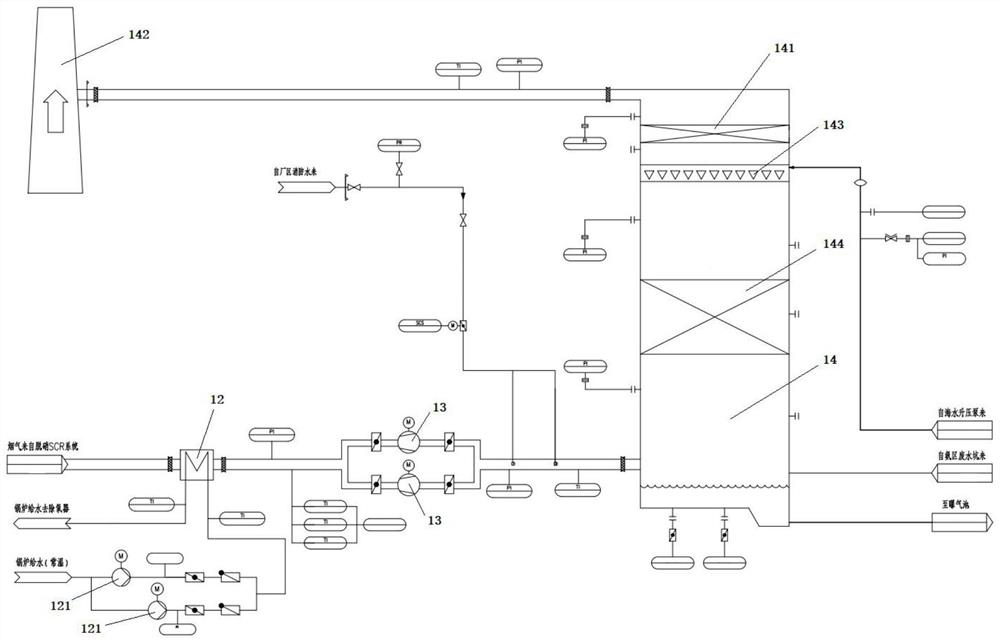

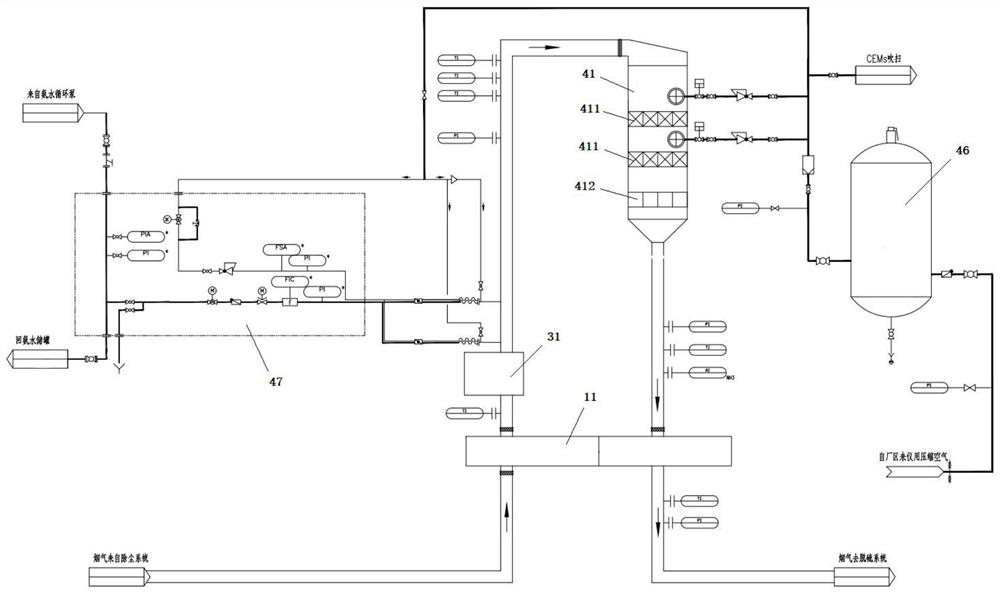

[0044] like Figure 1 to Figure 5 As shown, this embodiment provides an integrated system for dust removal, denitration and desulfurization, including a seawater desulfurization system, a bag dust removal system, a hot blast stove system and a denitration system;

[0045] Seawater desulfurization system includes flue gas system, SO 2 Absorption system, seawater supply system, seawater recovery system, and corresponding electrical system and thermal control system;

[0046] The flue gas system includes a flue gas heat exchanger 11, a waste heat recovery device 12, a booster fan 13; SO 2The absorption system includes an absorption tower 14; the seawater supply system includes a seawater intake...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com