Engine block for an internal combustion engine of a motor vehicle, and method for producing an engine block for an internal combustion engine of a motor vehicle

A technology of engine body and internal combustion engine, which is applied in the direction of machines/engines, engine components, cylinders, etc., and can solve the problems of increased frictional power consumption and consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

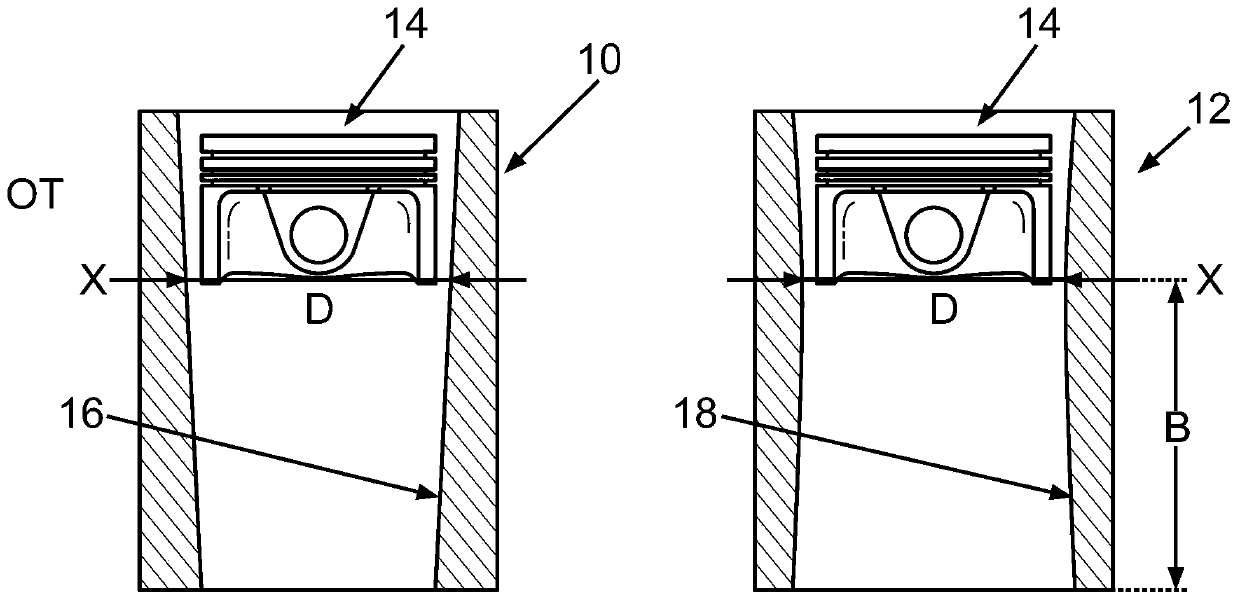

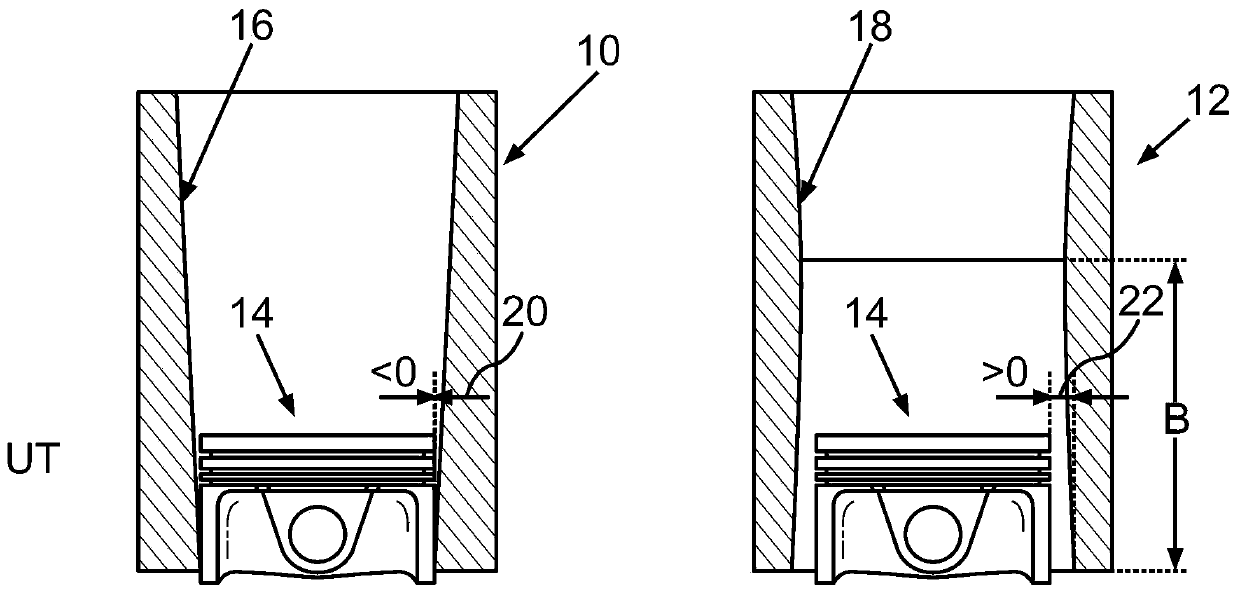

[0019] figure 1 It is a side sectional view of two different cylinders 10 , 12 which are each part of an internal combustion engine not shown in detail. figure 1 The pistons 14 in are arranged in the top dead center OT. Cylinders 10, 12 are all in a state of warming that is reached after a period of time during the operation of the internal combustion engine after ignition. That is, the shape of the illustrated cylinders 10 , 12 corresponds to the shape that the cylinders 10 , 12 have when the internal combustion engine reaches normal operating temperatures during operation.

[0020] The two cylinders 10 , 12 differ with regard to the geometry of the cylinder running surfaces 16 , 18 . In the illustrated elevated state, the diameter D of the cylinder running surface 16 of the left cylinder 10 decreases towards the bottom dead center UT of the piston 14 . That is to say that the cylinder running surface 16 tapers downwards in this figure. And in the cooling state, that is, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com