Coal mining machine with collapse prevention function

A coal excavator and anti-collapse technology, which is applied in the field of coal excavators with an anti-collapse function, can solve the problem of not being able to automatically detect whether there are cracks on the top of the tunnel, and achieve the effects of preventing blockage, increasing the detection range, and ensuring the observation field of view

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

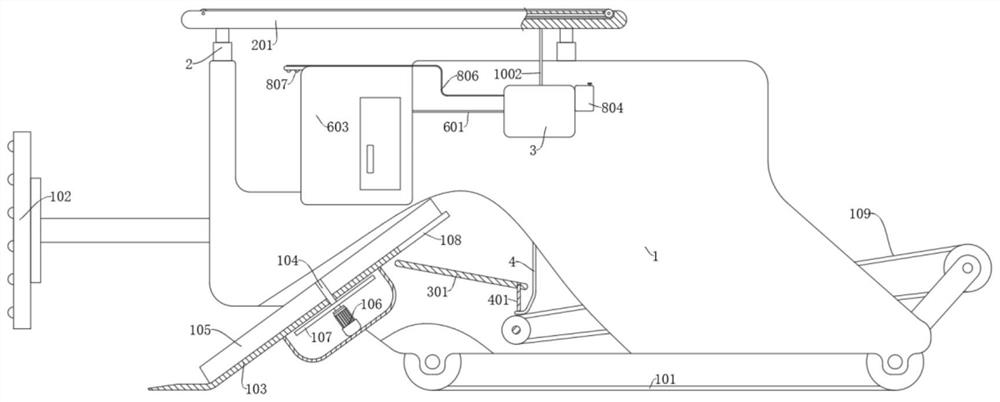

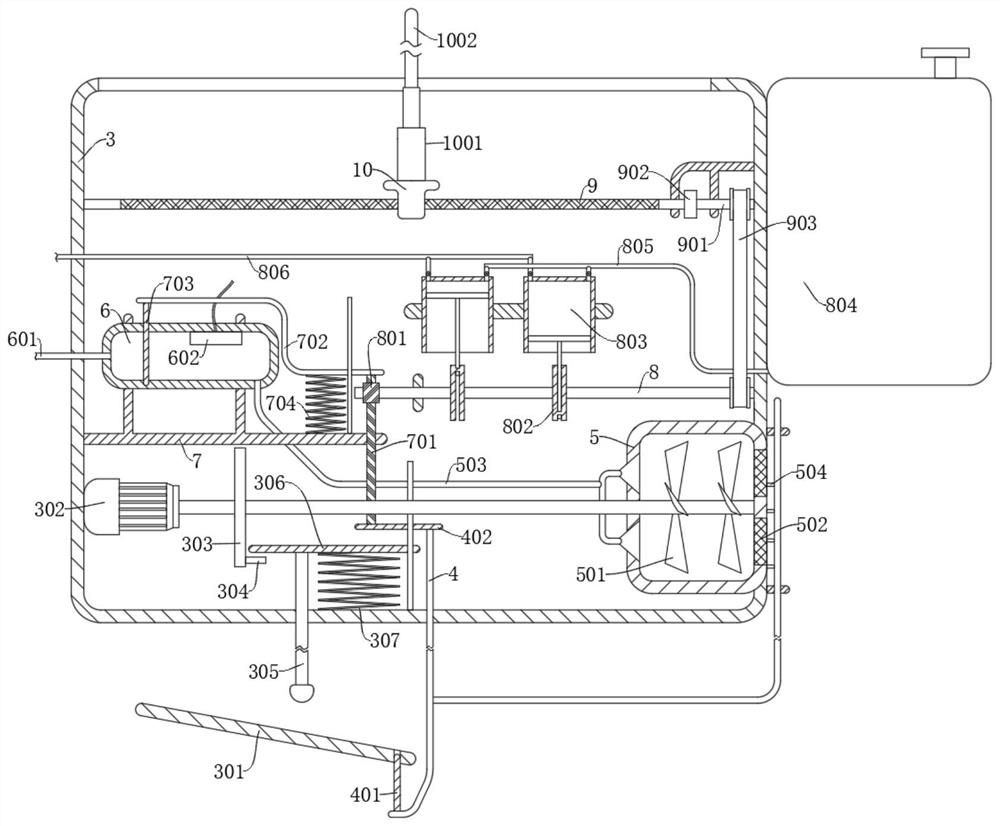

[0034] refer to Figure 1-9 , a coal shovel with anti-collapse function, including a body 1, a feeding plate 103 and a conveyor belt 109 connected to the body 1, and a cab 603 located on the body 1, and the front end of the body 1 is also connected with a The coal digging plate 102, or the coal digging teeth, the angle of which can be adjusted.

[0035] The function of the feeding board 103 is to automatically transport the coal mined by the coal digging board 102 to the conveyor belt 109 , and then transport it to an external conveyor belt through the conveyor belt 109 for transporting out.

[0036] The conveyor belt 109 is driven by a motor, or a power machine.

[0037] How the feeding plate 103 realizes the automatic transfer of coal to the conveyor belt 109 is explained as follows:

[0038] like figure 1 and 9, the feeding plate 103 is inclined and one end is attached to the ground. At the same time, two sets of first rotating shafts 104 are rotatably connected to the ...

Embodiment 2

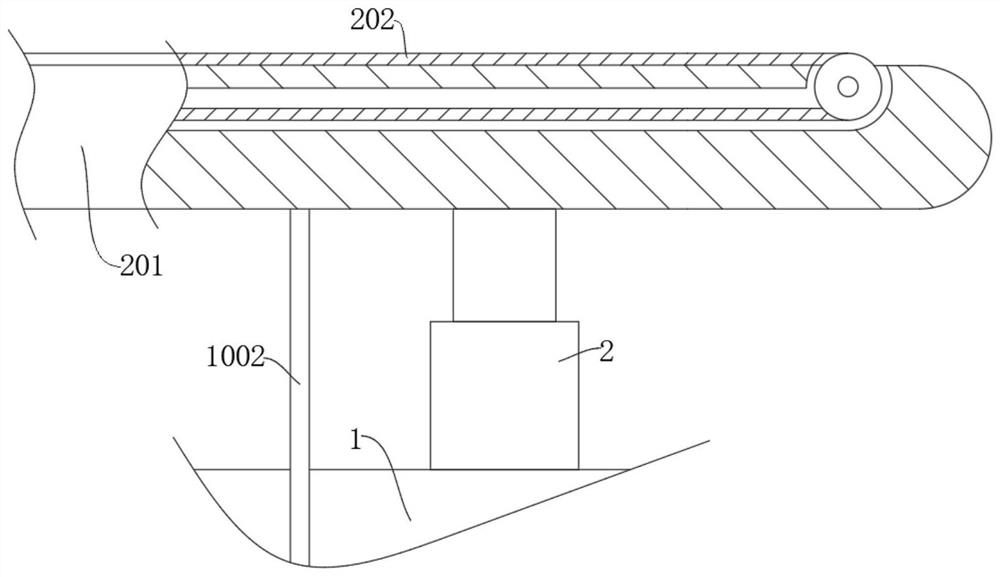

[0083] refer to Figure 1-9 , which is basically the same as Example 1. On the basis of Example 1, it is added that the gas in the cab 603 is simultaneously replaced while the coal is broken and whether there are cracks on the top of the tunnel, and the glass of the cab 603 is replaced simultaneously. Cleaning is carried out to ensure the clarity of the operator's field of view.

[0084] Because in the underground tunnel, the environment is relatively harsh, and there is a lot of dust in the air. In order to ensure the health and safety of the operators in the cab 603 of the coal excavator, it is necessary to constantly replace the gas in the cab 603 to improve the fluidity. In addition, due to the large amount of dust, if the glass of the cab 603 is not cleaned, a layer of dust will adhere to it after a period of time, which reduces the clarity of the operator's observation field and makes it inconvenient to accurately operate the shovel.

[0085] like figure 1 , 3 8. In o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com