Production and processing equipment for stainless steel pipe

A technology for processing equipment and stainless steel pipes, applied in the field of alloys, can solve the problems of increasing the volume and weight of equipment, increasing the risk of collapse, and low transmission efficiency of steel pipes, saving time and physical strength, labor consumption and physical strength. The effect of improving production and processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

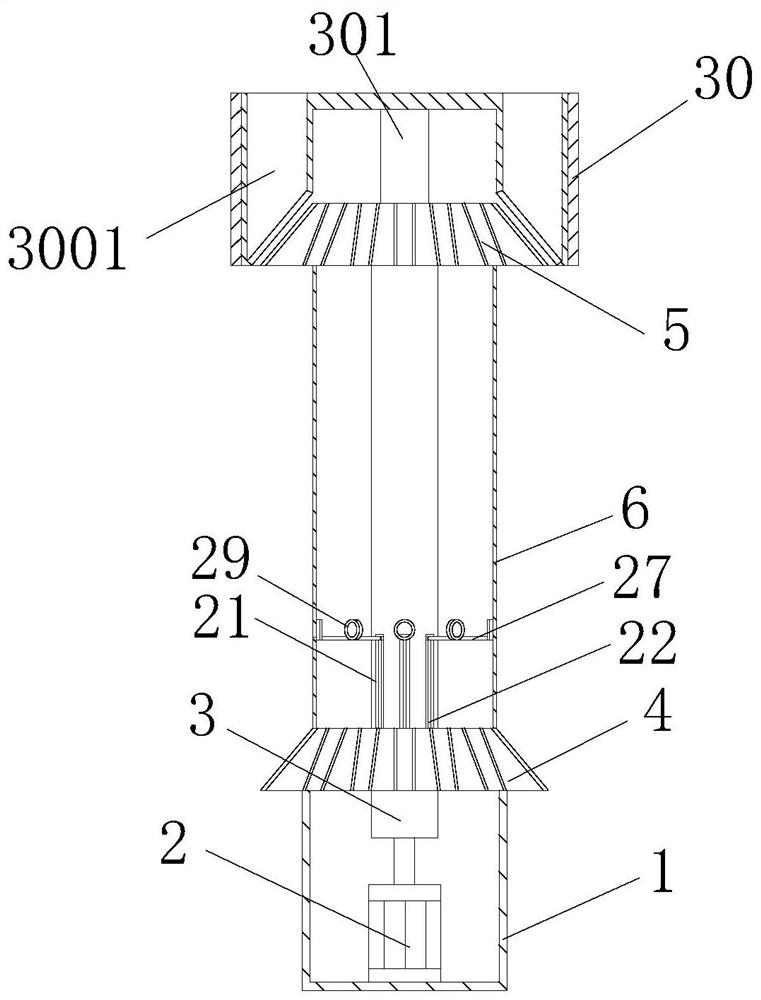

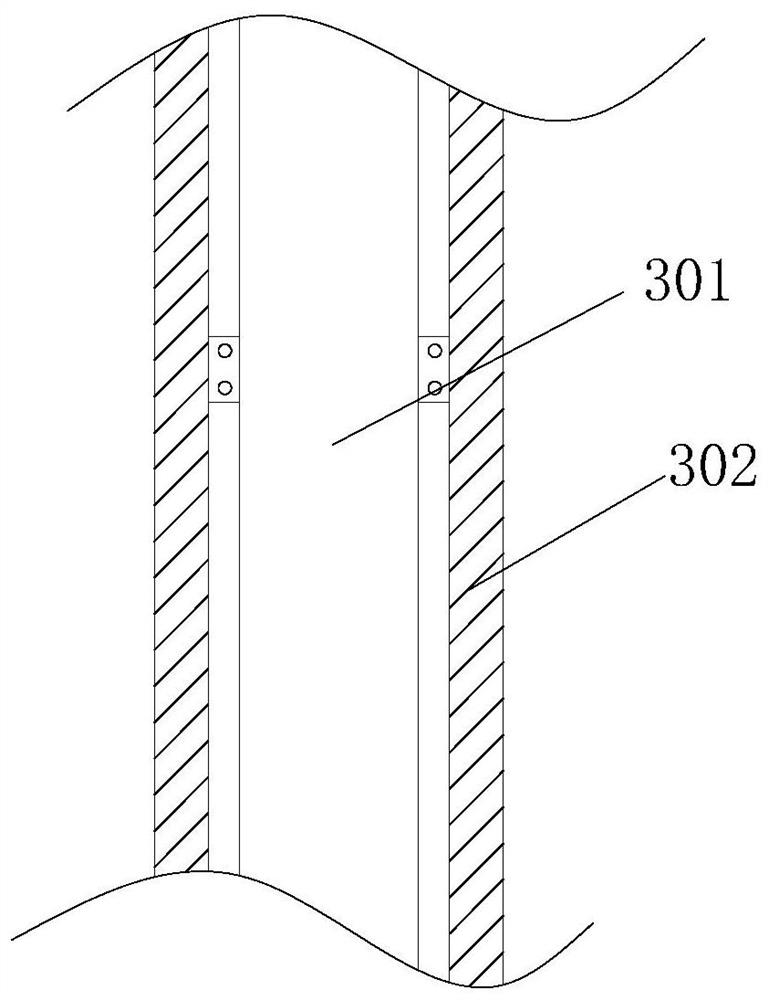

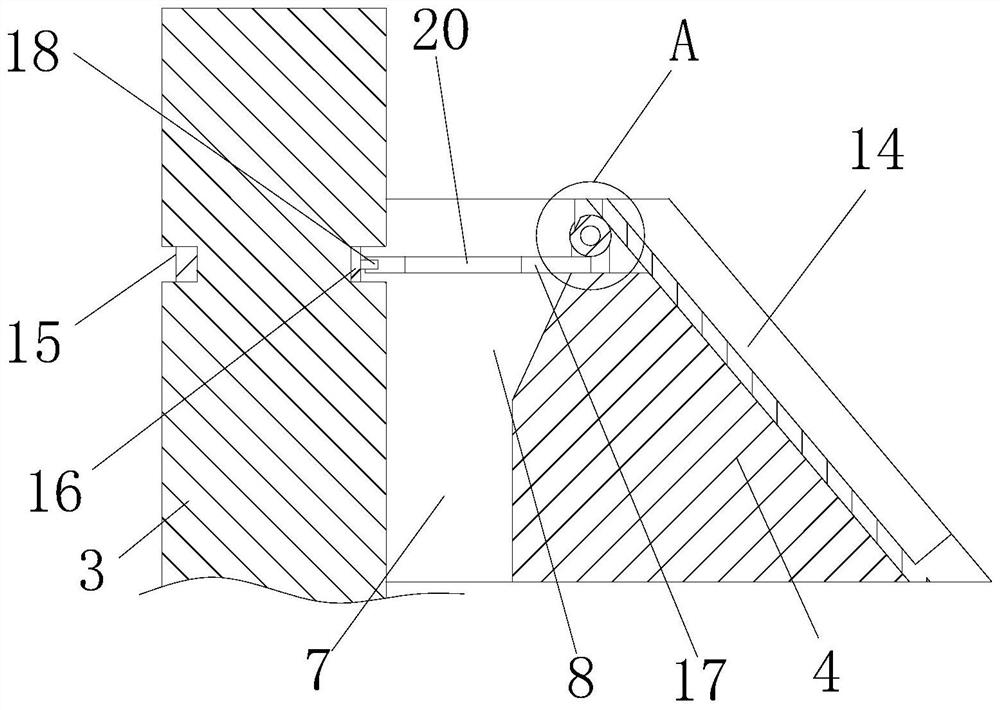

[0048] Example 1: Please refer to Figure 1-10 , the present invention proposes a stainless steel pipe production and processing equipment, including a base 1, a rotating motor 2, a central shaft 3, an upper conveying frame 4 and a lower conveying frame 5, the top surface of the base 1 is hollowed out and the inner wall of the bottom surface is connected to the rotating motor 2 Fixedly connected, the central shaft 3 includes an inner column 301 and an outer column 302. The center of the outer column 302 is hollowed out and the inner wall is fixedly equipped with a rotating bearing. The inner ring of the rotating bearing is fixedly connected with the inner column 301. The transmission shaft of the rotating motor 2 is connected to The inner column 301 is fixedly connected, the top surface of the base 1 is fixedly connected with the upper conveying frame 4, the outer edge of the top surface of the upper conveying frame 4 is fixedly connected with a protective frame 6, and the top ...

Embodiment 2

[0051] Example 2: Please refer to Figure 11-15 On the basis of Embodiment 1, the outer wall of the protective frame 6 is fixedly connected with three spacer rings 31 at equal intervals, and the side of the spacer ring 31 corresponding to the protective frame 6 is in a hollow state, and the outer wall of the protective frame 6 and the outer column 302 are correspondingly transported The positions of the upper semi-cylindrical grooves of the frame 4 are all provided with holes, the inner wall of the limit ring 31 is sleeved with a guide ring C32, and the end of the guide ring C32 away from the limit ring 31 fits with the inner column 301, and the top surface of the guide ring C32 is provided with Guide hole 33, guide hole 33 is made up of round platform hole and cylindrical hole, and the side with small diameter of round platform hole is downward, and the inner wall of cylindrical hole on the guide hole 33 is fixedly connected with hairbrush 34, and when inner column 301 rotates...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com