Automatic spraying machine capable of achieving uniform spraying

An automatic spraying and mechanical technology, applied in the direction of spraying devices, etc., can solve the problems of damage to spraying machinery, etc., and achieve the effects of avoiding poor flow, easy operation, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

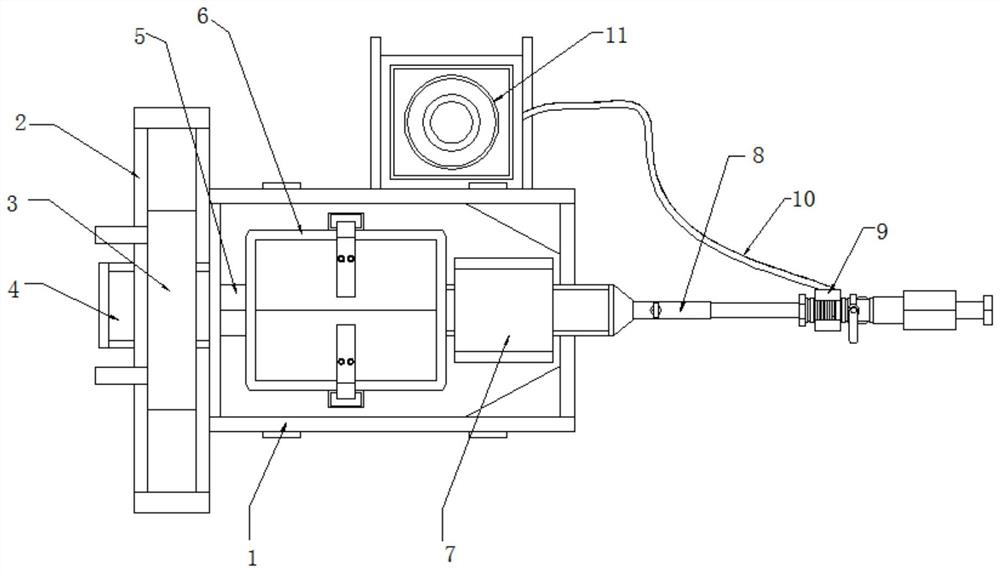

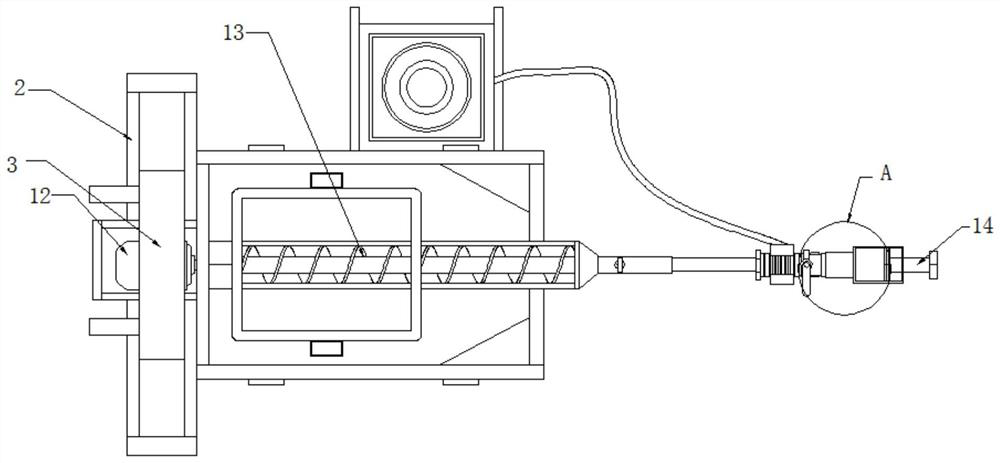

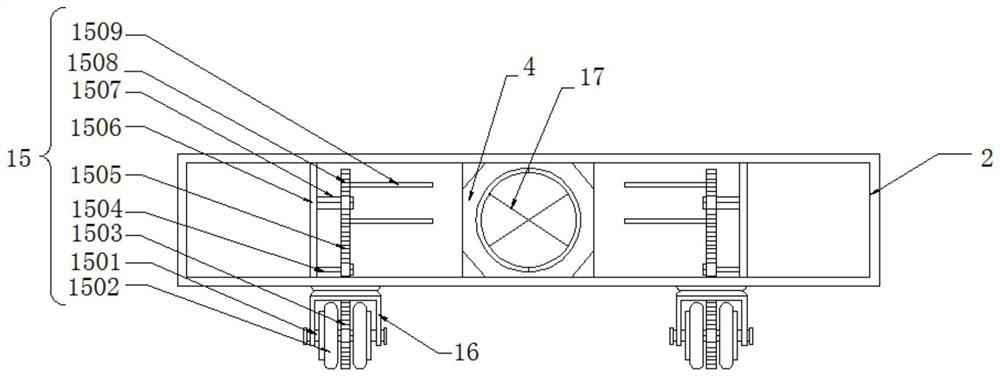

[0030] see Figure 1 to Figure 7, the present invention provides a technical solution: an automatic spraying machine that can spray evenly, including a support frame 1, a connecting frame 2, an auxiliary frame 3, a motor cavity 4, a connecting barrel 5, a first material barrel 6, an auxiliary ring 7, and a connecting pipe 8. Nozzle 9, connecting pipe 10, air compressor 11, motor 12, threaded rod 13, cross rod 14, heat dissipation assembly 15, auxiliary shaft 1501, roller 1502, first gear 1503, first horizontal shaft 1504, second Gear 1505, vertical plate 1506, second horizontal shaft 1507, third gear 1508, auxiliary blade 1509, fixing frame 16, dust cover 17, dustproof assembly 18, connecting side block 1801, connecting shaft 1802, dustproof pad 1803 , hydraulic air rod 1804, adjustment assembly 19, top plate 1901, adapter plate 1902, center rod 1903, rubber pressure pad 1904, electric push rod 1905, bottom plate 20, second barrel 21, auxiliary assembly 22, heating wire 2201, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com