Camera lens coating equipment with antifouling structure for intelligent manufacturing of mobile phone

A technology of intelligent manufacturing and coating equipment, which is applied in the direction of sputtering coating, ion implantation coating, vacuum evaporation coating, etc., can solve the problems of interference pollution, coating influence, and insufficient purity inside the vacuum coating machine, etc., to maintain purity, It is convenient for unloading processing and automatic transmission processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

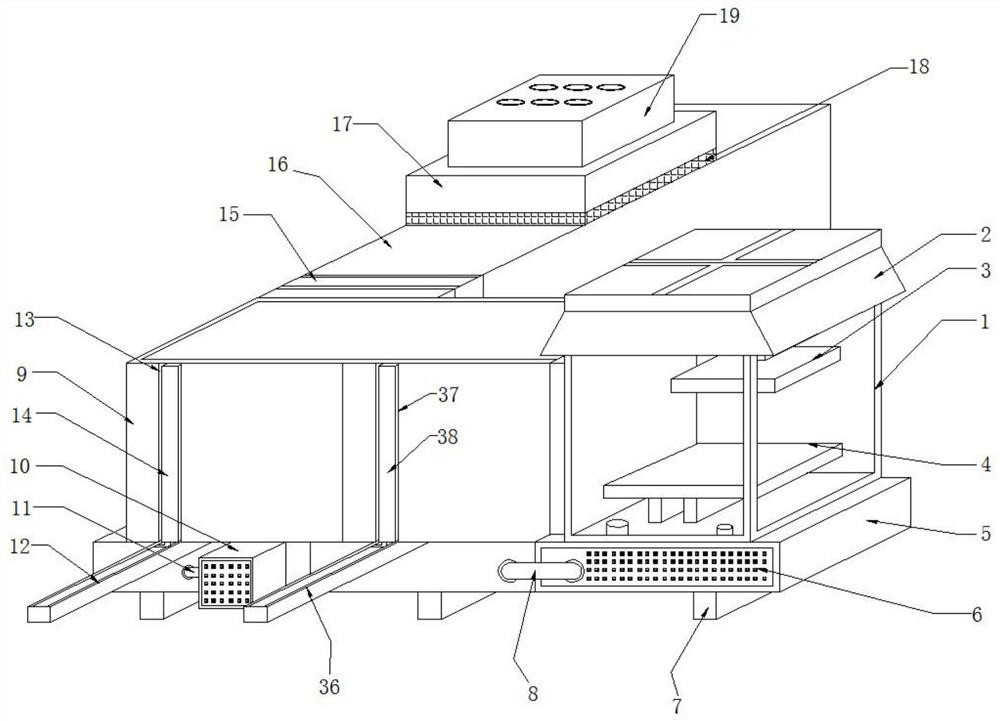

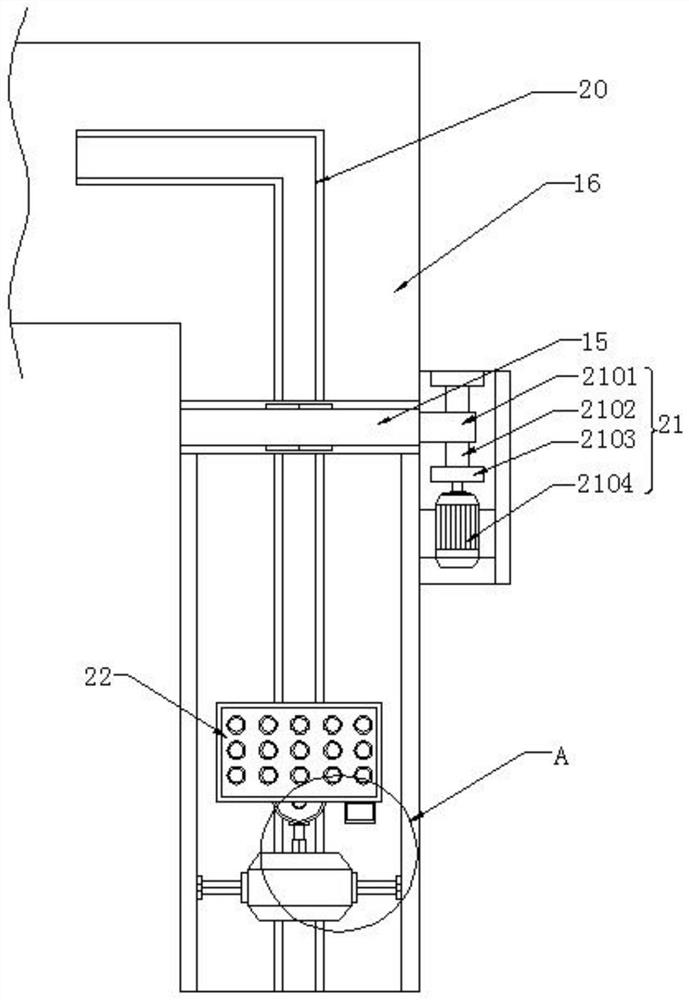

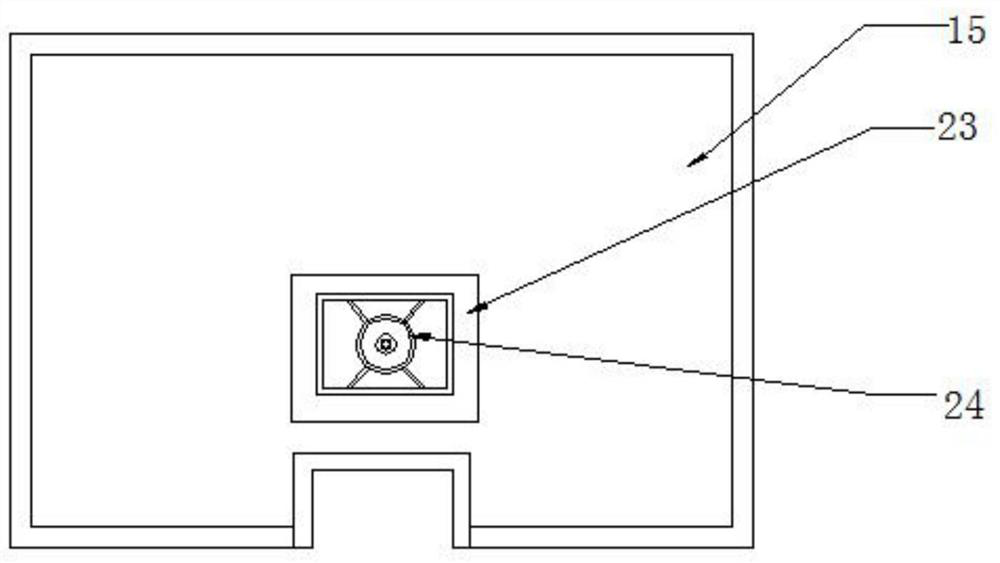

[0029] see Figure 1 to Figure 6, the present invention provides a technical solution: a camera lens coating device with an antifouling structure for smart mobile phone manufacturing, including a coating machine 1, a top cover 2, a target body 3, an anode plate 4, a connecting bottom frame 5, a vent 6, a base Seat 7, connecting pipe 8, connecting frame 9, vacuum pump outer frame 10, connecting pipe 11, first electric slide rail 12, first limit groove 13, first built-in partition 14, auxiliary plate 15, extension frame 16 , Buffer chamber 17, Heating wire mesh plate 18, Air pump outer frame 19, Second electric slide rail 20, Adjustment assembly 21, Connecting plate 2101, Connecting shaft 2102, Fixed sleeve plate 2103, Motor 2104, First base plate 22, Built-in groove 23. Distance sensor 24, first hydraulic air rod 25, second hydraulic air rod 26, connection frame 27, slider 28, side brush 29, auxiliary vertical brush 30, servo motor 31, fixed plate 32, heat dissipation port 33, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com