Single pipe grabbing control system under deep hypothermia cold chain environment

A control system, cryogenic technology, applied in the control system, motor generator control, manufacturing tools, etc., can solve the problems of large space limitations, tube stuck or dropped, easy to hit the sample tube, etc., to achieve high efficiency and reliability Effect of controlling and preventing low temperature failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

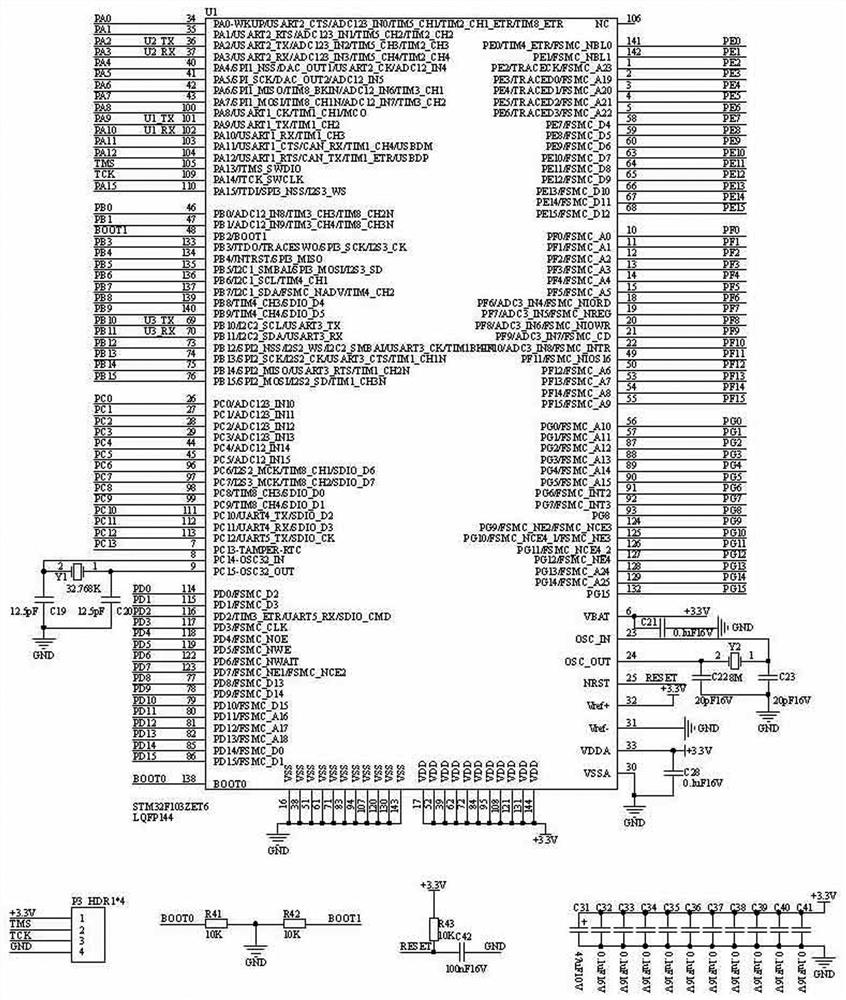

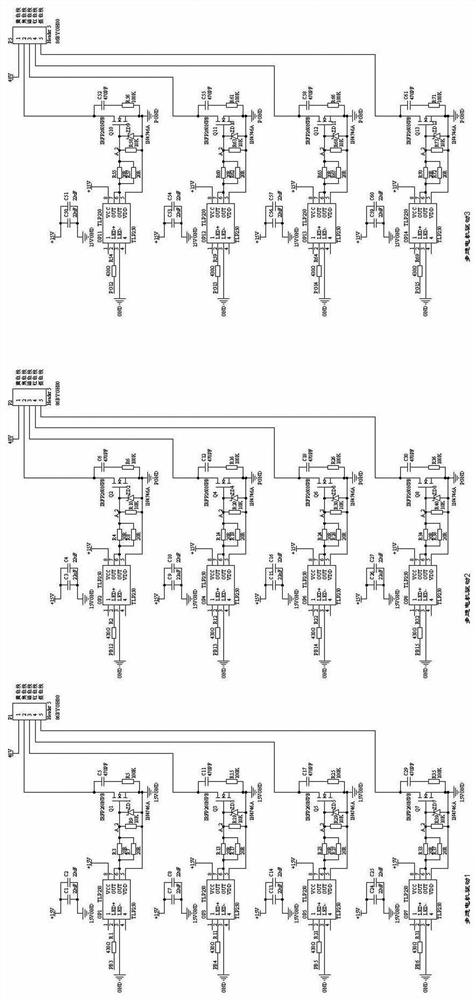

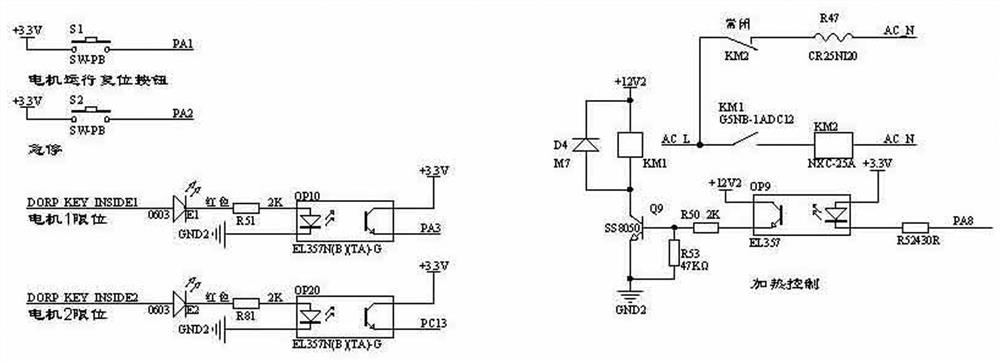

[0042] As shown in the figure, the single-tube grabbing control system in the cryogenic cold chain environment of the present invention can be applied to the single-tube grabbing device in the cryogenic cold chain environment. The single-tube grabbing device in the cryogenic cold chain environment includes an external The sleeve, the inner and upper part of the outer sleeve is provided with a rotating control rod, the upper end of the rotating control rod protrudes from the outer sleeve and is connected with a bevel gear, the lower end of the rotating control rod is provided with a grab hook and a rotary grab hook release device, and the lower end of the rotary grab hook release device A connection frame is arranged in the grabbing hook, a striker spring and a striker are arranged in the connection frame, and the striker is arranged at the lower end of the striker spring;

[0043] The lower end of the grab hook is provided with a claw head built-in striker, the upper end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com