Fully automatic high pressure gas injection control system

A high-pressure gas and control system technology, applied in the field of automatic high-pressure gas injection control system, can solve the problems of unadjustable output gas pressure and flow rate of gas-assisted injection equipment, low production efficiency, and non-presettable gas injection time, etc., to achieve Efficient and reliable effect of control process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

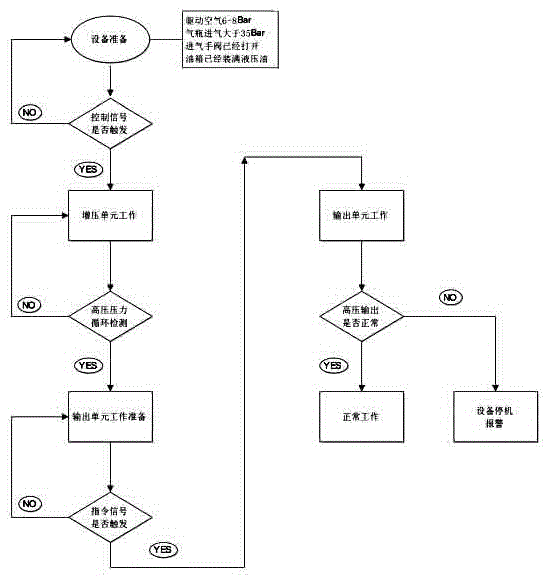

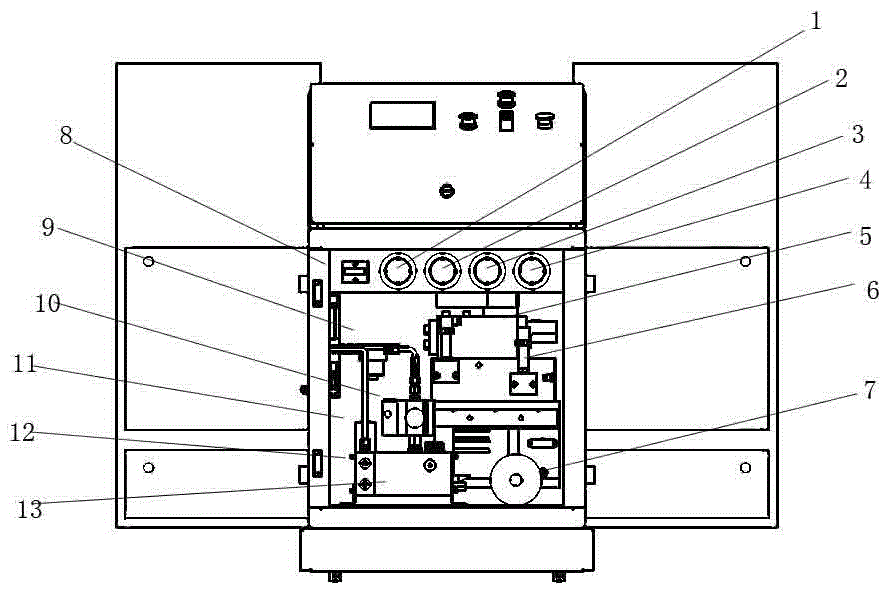

[0014] Below in conjunction with accompanying drawing, content of the present invention is described further:

[0015] The automatic high-pressure gas injection control system is mainly composed of the following 10 main parts:

[0016] 1. Gas booster; 2. A set of air intake control device, including intake stop valve, intake stop valve, intake filter, gas cylinder pressure gauge and gas cylinder pressure transmitter; 3. High pressure gas buffer device One set, including gas storage tank, safety valve of gas storage tank, unloading valve of gas storage tank and pressure gauge of gas storage cylinder; 4. One set of air drive device, including driving air filter, driving air pressure gauge, driving air Pressure regulating valve, driving air safety valve, two-position three-way driving air solenoid valve and two-position three-way driving air solenoid valve; 5. Liquid drive pressure flow proportional valve and liquid drive pressure flow proportional valve block; 6. Liquid drive de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com