A method for controlling and adjusting stitch distance on a sewing machine

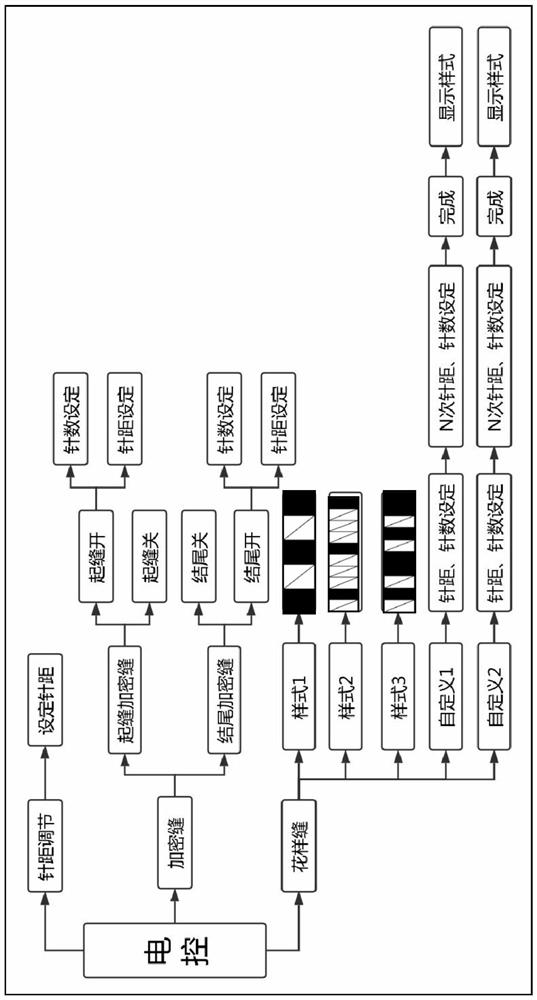

A technology of control adjustment and needle pitch adjustment, which is applied in the direction of sewing machine components, program-controlled sewing machines, sewing equipment, etc. It can solve the problem that the number of encrypted stitches cannot be accurately controlled and changed, it is difficult for users to observe and adjust, and the action of electromagnets Difficult to control and other problems, to achieve the effect of efficient and reliable control, high degree of automation, and fast response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

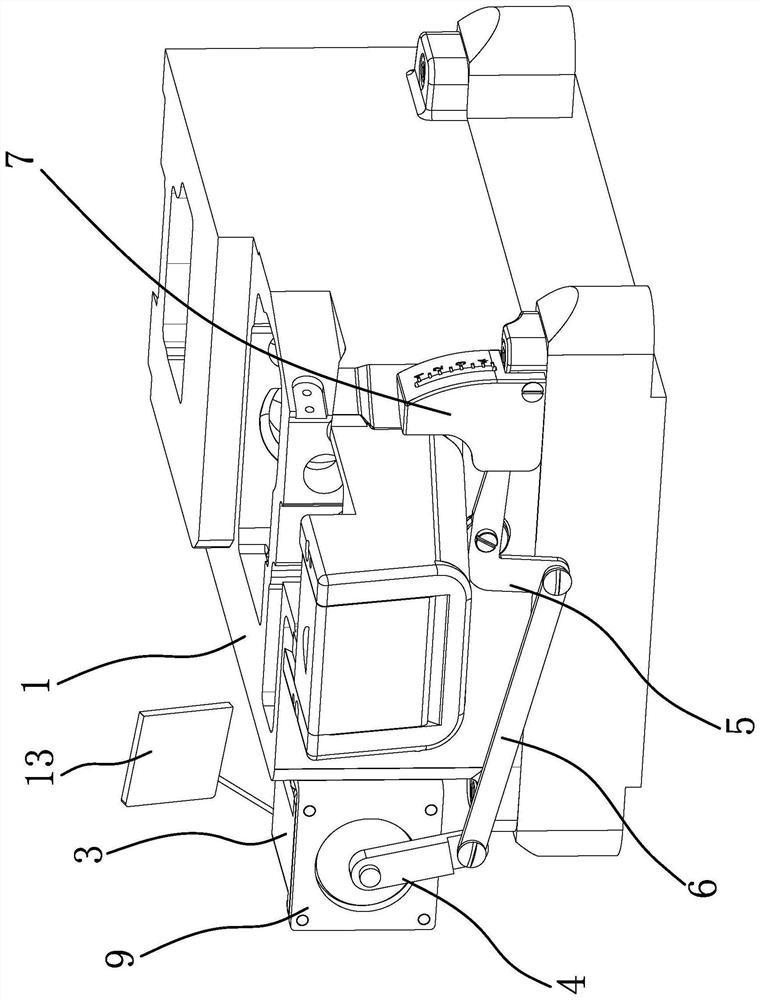

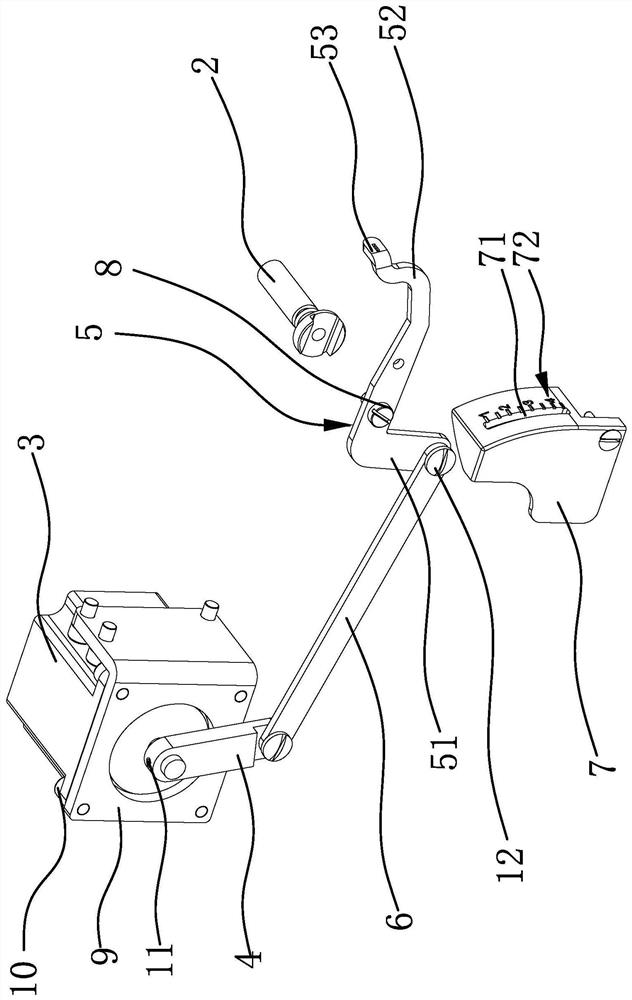

[0033] like figure 1 and figure 2As shown, the sewing machine includes a machine casing 1 and a cloth feed dog, the cloth feed dog is arranged on the cloth feed dog frame, a drive motor 3 and a rotatable needle distance adjustment shaft 2 are arranged on the machine case 1, and the needle distance adjustment shaft 2 can be adjusted The single movement distance of the feed dog, a cam or crank structure can be set on the needle distance adjustment shaft 2, and then connected with the cloth feed pendulum rod, which is used to adjust the moving position of the cloth feed dog frame. Through the rotation of the needle distance adjustment shaft 2, the feed dog The swing angle of the cloth pendulum rod changes, and finally the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com