Connecting structure for lift supporting beam of vertical take-off and landing aircraft

A technology of vertical take-off and landing aircraft and connection structure, applied in aircraft parts, fuselage, rotorcraft, etc., can solve the problems of heavy motor weight, low driving efficiency, short flight time, etc., and achieve the effect of convenient return to the factory for maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

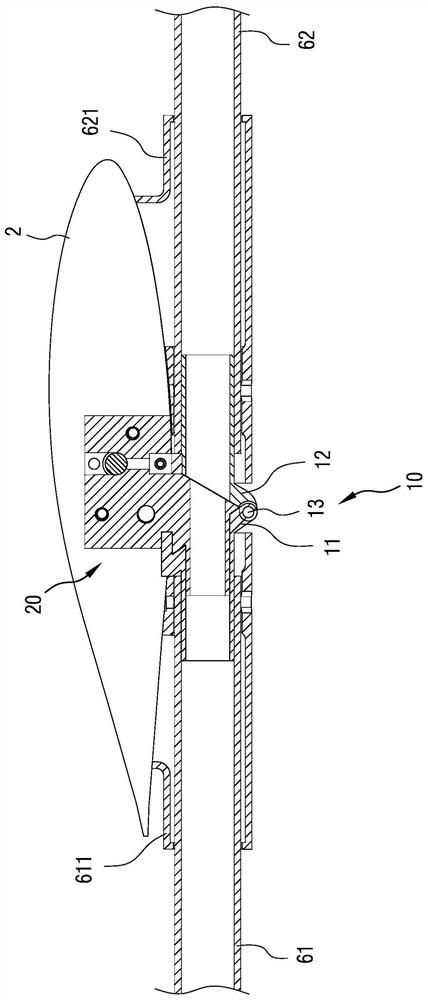

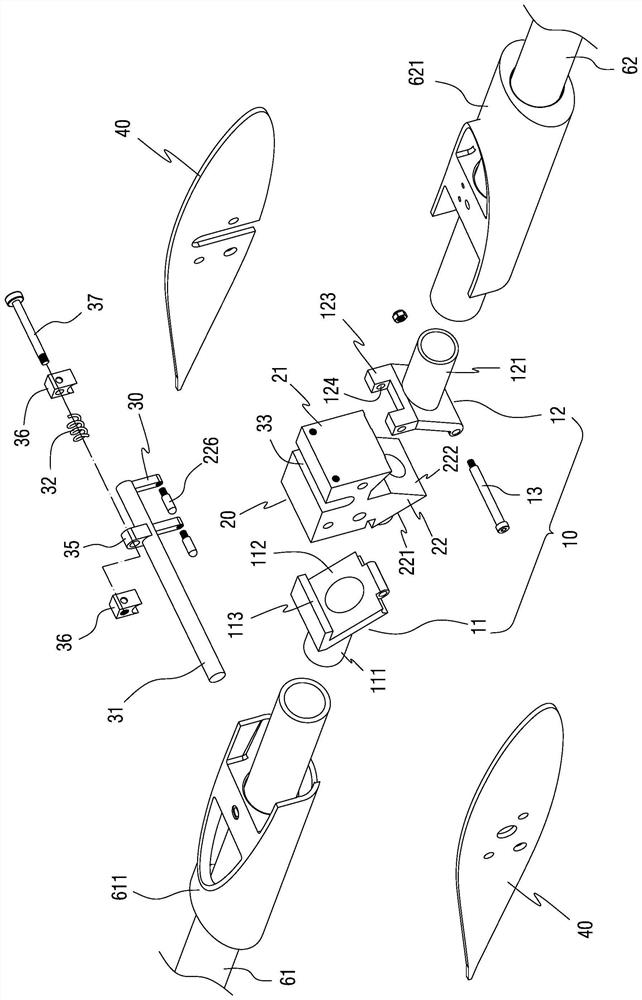

[0023] In order to have a clearer understanding of the technical features, objects and effects of the present invention, the specific embodiments of the present invention will now be described with reference to the accompanying drawings. Wherein, the same parts use the same reference numerals.

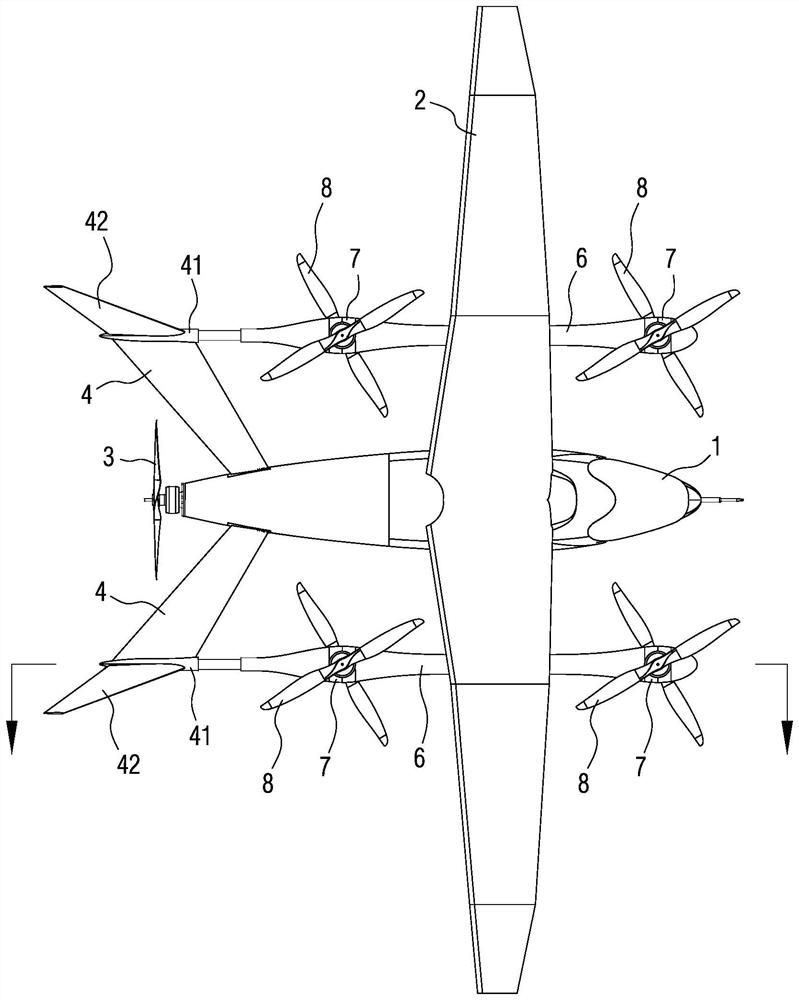

[0024] like figure 1 As shown, the present invention provides a vertical take-off and landing aircraft with a conventional upper monoplane layout, including a wing 2 arranged on a fuselage 1, a propulsion propeller 3 located at the end of the tail of the fuselage 1, a propeller 3 arranged on the fuselage The horizontal stabilizer 4 on both sides of the tail of the 1, and the lower part of the fuselage 1 is provided with a conventional landing gear structure (not shown in the figure). The vertical take-off and landing aircraft of the present invention adopts a conventional layout and can glide and take off like an ordinary aircraft. The advantages of this design are simple structure an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com