Efficient roadbed flattening device for highway engineering construction

An engineering and subgrade technology, applied in the field of high-efficiency subgrade flattening devices, can solve the problems of compacted road surface with potholes, etc., and achieve the effect of simple operation and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

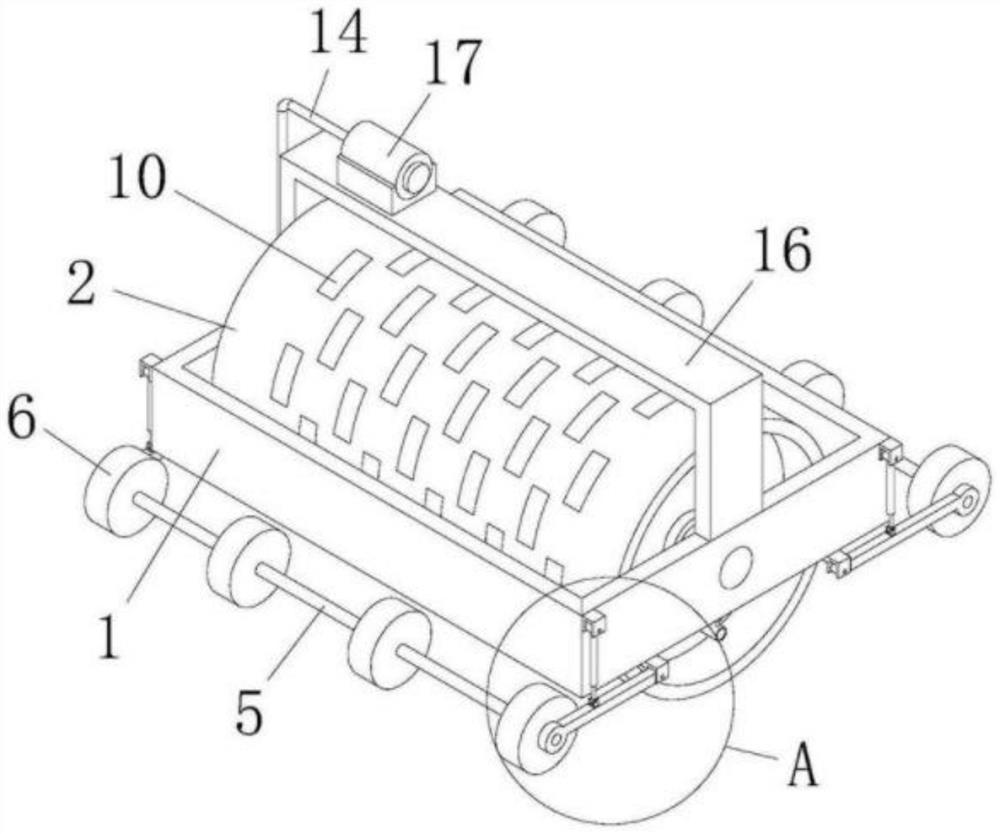

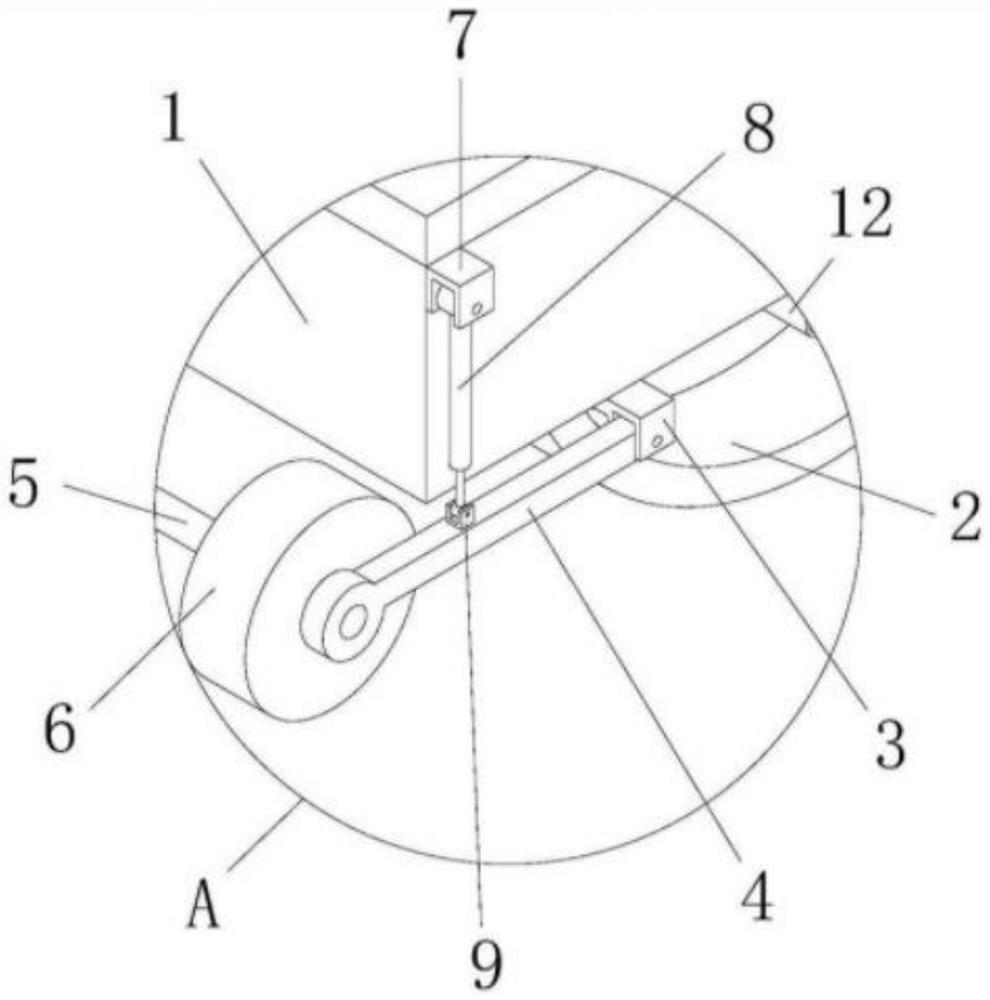

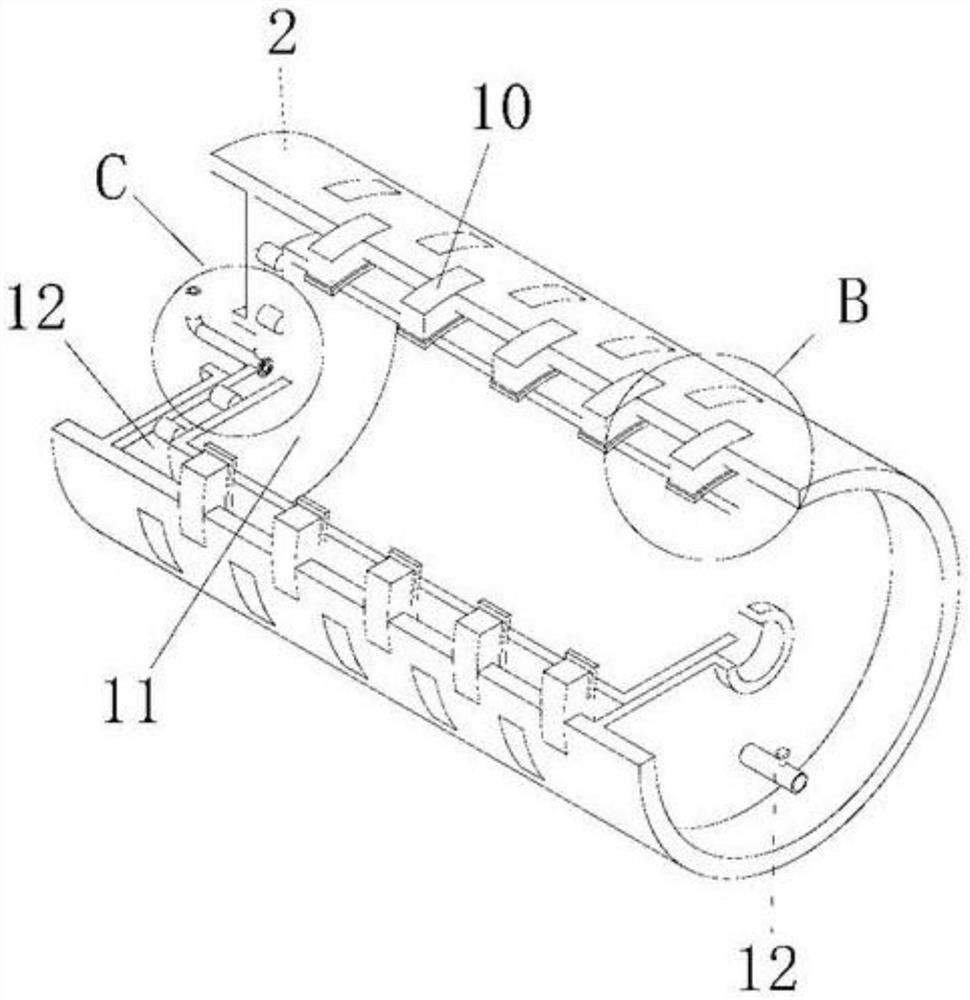

[0037] Example: a high-efficiency subgrade leveling device for highway engineering construction, such as Figure 1-Figure 6 As shown, it includes a pinch roller holder 1 and a pinch roller body 2. The left and right ends of the pinch roller body 2 are respectively connected to the left and right inner walls of the pinch roller holder 1 through rotating shafts, and the outer wall of the pinch roller body 2 is circumferentially Holes are evenly distributed, each hole is provided with a rolling slider 10, the inside of the roller body 2 is provided with a weight-adjusting inner cylinder 11, and the top surfaces of the left and right ends of the roller holder 1 are fixedly connected with brackets 16. An air pump 17 is fixedly connected to the top surface of the left end of the bracket 16, and two support links 4 are respectively provided on the left and right sides of the bottom end of the pressing wheel fixing frame 1, and the top surface of each support link 4 is respectively pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com