Road surface unevenness measuring device

A road surface and measuring device technology, applied in the directions of roads, roads, road repair, etc., can solve the problems of small detection area and unscientific and rigorous road surface smoothness, and achieve the effect of large measurement area and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

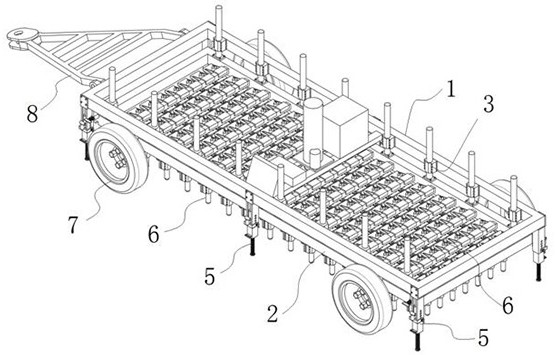

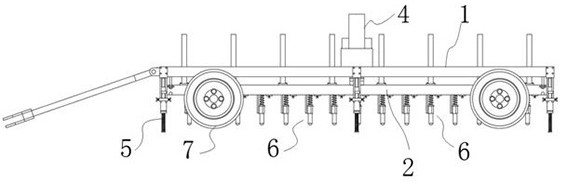

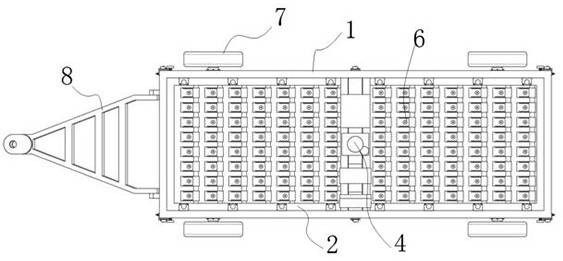

[0038] see Figure 1-4 As shown, the present invention is a road surface roughness measuring device, comprising an outer frame 1 and an inner frame 2; the inner frame 2 is linearly guided and matched with the outer frame 1 through a plurality of first linear ball guide bushes 3; There is a telescopic drive device 4 for driving the inner frame 2; a number of support adjustment devices 5 are installed on the periphery of the outer frame 1; a number of telescopic displacement measuring devices 6 are installed on the inner frame 2; four wheels 7 are installed on the outer frame 1; One end of the frame 1 is connected to the tractor through a trailer connecting frame 8 ; a power supply 9 and a signal collection display 10 are also installed on the outer frame 1 , and the signal collection display 10 is provided with a memory.

[0039] like Figure 5 As shown, the outer frame 1 includes a rectangular outer frame 101; the lower surfaces of the two frames in the length direction of th...

specific Embodiment 2

[0043] On the basis of the specific embodiment 1, the differences of this embodiment are:

[0044] like Figure 8-10 As shown, the support adjustment device 5 includes a guide groove body 51 connected with the outer frame 1, a jack 52 matched with the guide groove body 51, and a support slider 53; the guide groove body 51 includes an L-shaped plate 511; the L-shaped plate 511 It is connected with the outer frame 1 by bolts; the lower surface of the L-shaped plate 511 fixes the rectangular tube 512; the rectangular tube 512 is provided with a rectangular through slot 513 in the middle part; hole 514; the support slider 53 includes a rectangular column 531 slidably matched with the inner wall of the rectangular tube 512; a threaded through hole is opened at the axis of the rectangular column 531, and a threaded support column 532 is threaded on the threaded through hole; the upper end of the rectangular column 531 is An E-shaped support plate 533 is fixed on the same side of th...

specific Embodiment 3

[0046] On the basis of the second specific embodiment, the differences of this embodiment are:

[0047] like Figure 11 As shown, the telescopic displacement measuring device 6 includes a magnetostrictive displacement sensor 61, a second linear ball guide bush 62, a cylinder 63, a spring 64, and a mounting seat 65; the magnetostrictive displacement sensor 61 is threadedly mounted on the mounting seat 65; The mounting seat 65 is installed on the rectangular cross bar 23; the cylindrical cylinder 63 is linearly guided and matched with the second linear ball guide sleeve 62, and the upper end of the cylindrical cylinder 63 is provided with a limit ring plate 631; the second linear ball guide sleeve 62 is fixed and installed on the On the mounting seat 65; the magnetostrictive displacement sensor 61 coincides with the axis of the second linear ball guide 62, the cylinder 63 and the spring 64; the spring 64 is arranged between the limit ring plate 631 and the opposite surface of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com