Plugging mechanism for double-chamber shell steam detection tool

A double-chamber, shell technology, applied in the sealing of the engine, the use of liquid/vacuum for liquid tightness measurement, mechanical equipment, etc., can solve the problem of leakage, the inability to correctly judge the shell, and the inability to accurately judge, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The following are specific embodiments of the present invention and the accompanying drawings to further describe the technical solutions of the present invention, but the present invention is not limited to these embodiments.

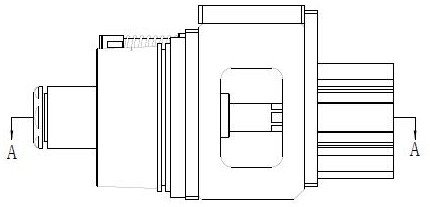

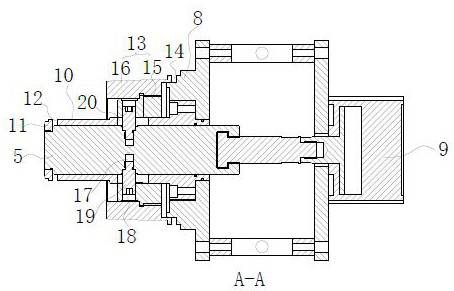

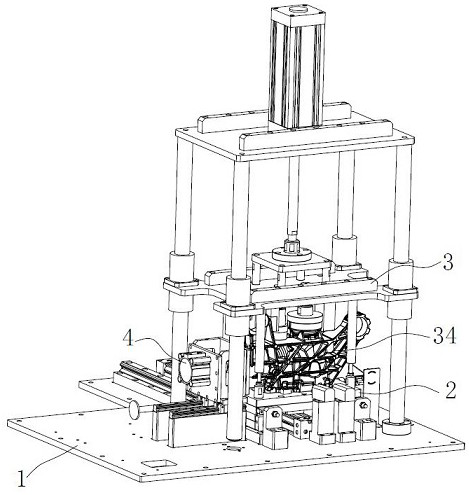

[0035] like Figure 1 to Figure 6 As shown, a plugging mechanism for a dual-chamber housing steam inspection tooling of the present invention includes: a base 1, a bottom plugging assembly 2, which is movably arranged on the base 1, and the bottom plugging assembly 2 is used for The bottom of the housing 34 to be tested is blocked; the pressing component 3 is arranged above the base 1. When the housing 34 is placed on the bottom blocking component 2 and moved to the bottom of the pressing component 3, the pressing component 3 The casing 34 can be pressed on the bottom blocking assembly 2; the side blocking assembly 4 is movably arranged on the base 1 and is on the side of the bottom blocking assembly 2, and the side blocking assembly 4 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com