Vibration testing device and vibration simulation method for aircraft airfoil structure

A technology of vibration testing and airfoil, which is applied in the testing of machine/structural components, vibration testing, and aircraft component testing, etc. It can solve problems such as damage to the excitation rod, affecting the accuracy of vibration loading, and difficult large-scale vibration loading, etc., to avoid Pull-off and crush damage, reliable and stable clamping method, and the effect of ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

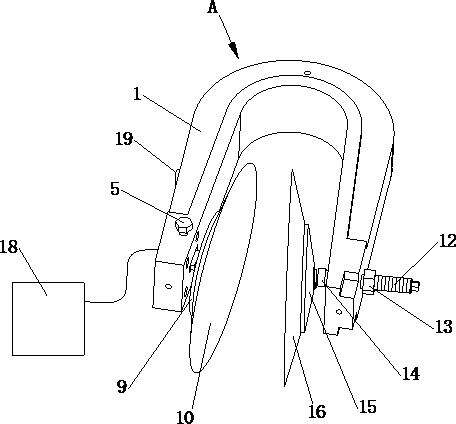

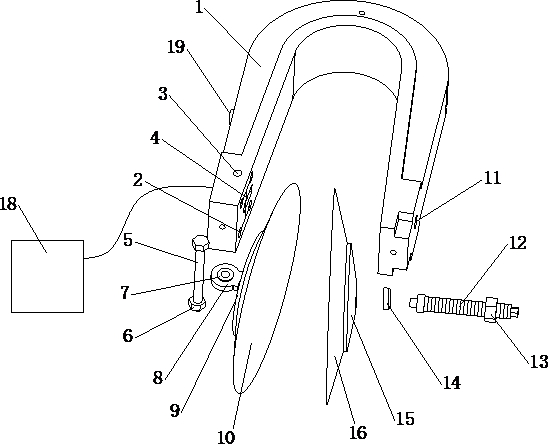

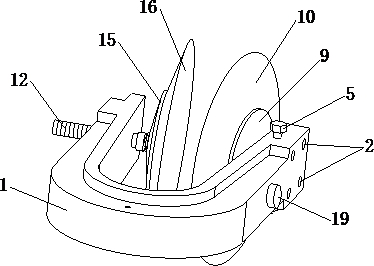

[0048] like Figure 1 to Figure 4 As shown, a vibration testing device for an aircraft airfoil structure of the present invention comprises a U-shaped piece 1, a left transmission mechanism and a right transmission mechanism respectively arranged on both sides of the U-shaped piece 1, and the U-shaped piece 1 A vibration exciter 18 that drives the U-shaped piece 1 to vibrate is provided on the upper side, and a dynamic force sensor 19 is provided on the left outer side of the U-shaped piece 1 .

[0049] The left transmission mechanism includes a pin 5 that is worn on the left side of the U-shaped piece 1 , an ear plate 8 that is sleeved on the pin 5 and extends out of the U-shaped piece 1 , and is connected to the ear plate 8 . The left conical piece 10 connected to and located on the inner side of the U-shaped piece 1, the ear plate 8 is embedded with a joint bearing 7 for the pin 5 to pass through.

[0050] The right transmission mechanism includes a threaded ejector rod 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com