Blade model reconstruction method supporting aerodynamic performance optimization

A technology for aerodynamic performance and model reconstruction, applied in the field of blade model reconstruction, can solve the problems of not supporting the optimization of the aerodynamic performance of the reconstructed model, not having the second function, etc., and achieving the effect of solving existing problems and strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

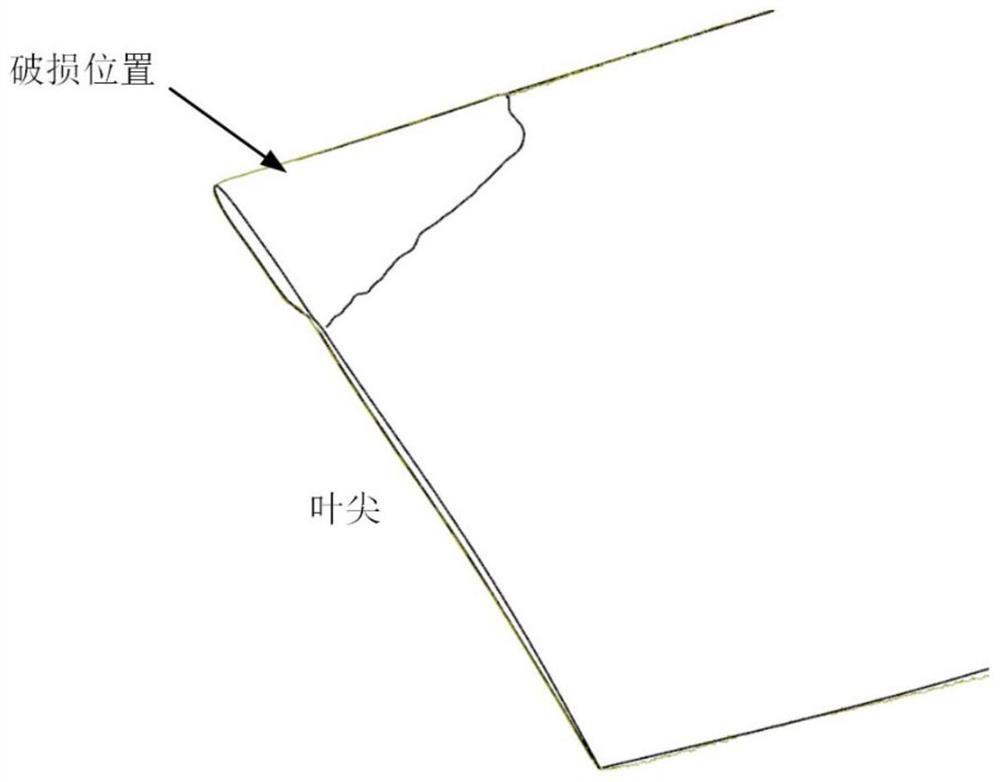

[0068] Taking a compressor blade as an example, the specific implementation of the present invention will be described. damaged leaves such as figure 1 As shown, the damage location is near the intersection of the leading edge and the blade tip, and the notch has been filled with solder by a laser cladding process.

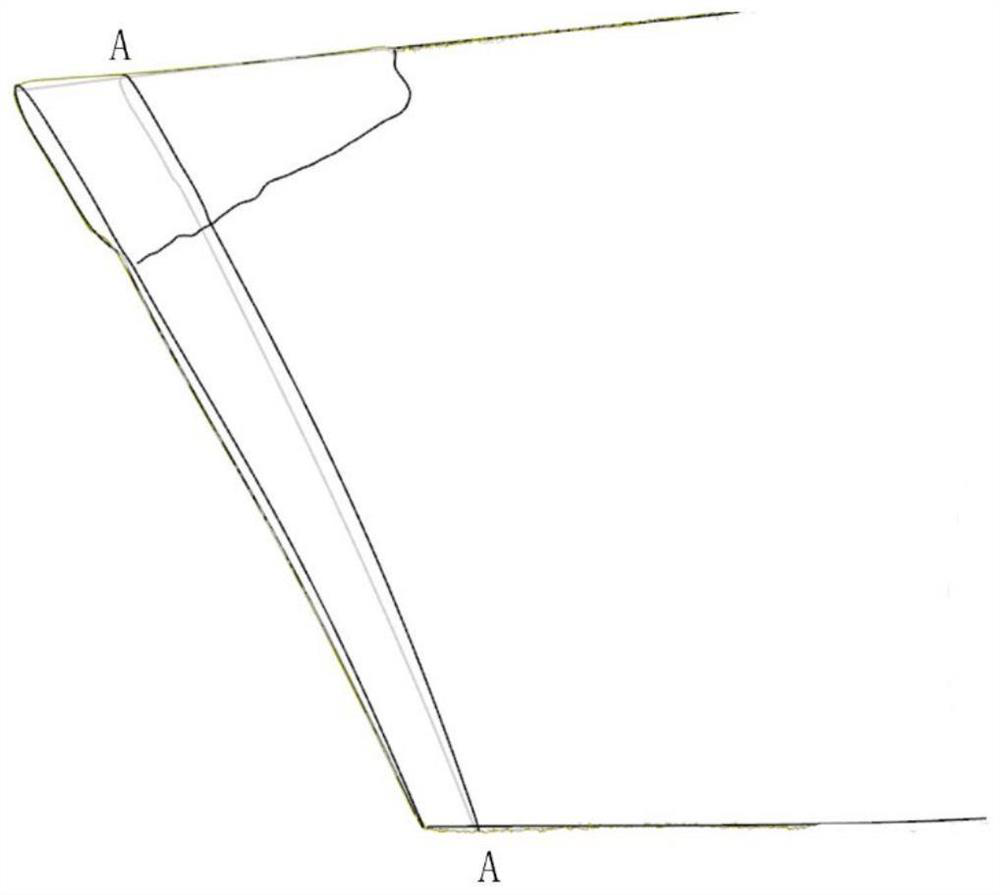

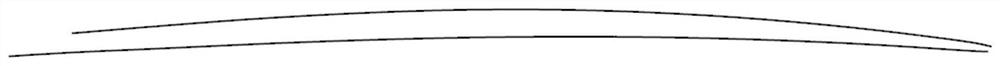

[0069] Cut the airfoil at the A-A section of the damaged position, such as figure 2 As shown, the resulting damaged blade shape is as follows image 3 shown. After analysis, there is deformation of the airfoil near the weld, such as Figure 4 As shown, the reconstructed airfoil curve needs to be smoothly connected to the unbroken curve to avoid overlapping of the blade surface.

[0070] Extract the mid-arc of the damaged blade shape, select initial repair parameters according to the blade design experience, and repair the damaged mid-arc. The curve of the missing area of the original damaged blade was generated according to the complete mid-arc line and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com