High-flexibility high-distortion-resistant cable with dynamic cable structure

A highly flexible and dynamic technology, applied in the direction of insulating cables, cables, circuits, etc., can solve the problems of limited effect and easy deformation of the structure, so as to prolong the service life, strengthen the flexibility and anti-torsion performance, and ensure the overall structural strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

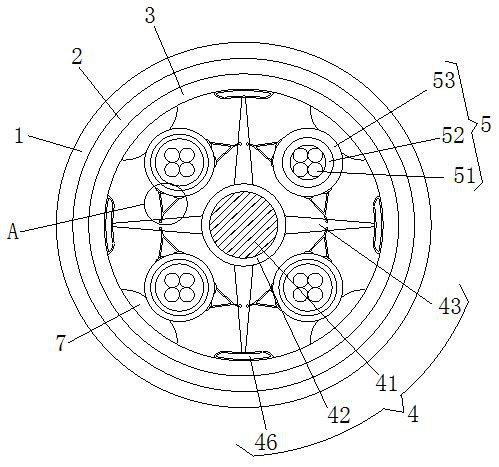

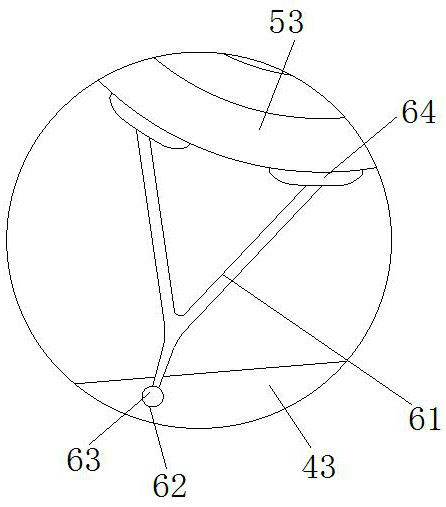

[0021] see Figure 1-3 , the present invention provides a technical solution: a high flexibility and high twist resistance cable with a dynamic cable structure, comprising a wear-resistant layer 1, the inner side of the wear-resistant layer 1 is sleeved with an outer insulating layer 2, and the inner side of the outer insulating layer 2 The outer buffer layer 3 is sleeved, a subsection support mechanism 4 is arranged in the outer buffer layer 3, and an inner cable 5 is also arranged in the outer buffer layer 3. The inner cable 5 consists of a wire core 51, an inner buffer layer 52 and an inner insulating layer. 53 is covered from the inside to the outside, and the inner cable 5 and the sub-section support mechanism 4 are connected by the dynamic support mechanism 6 .

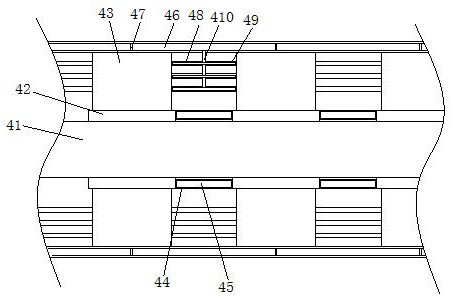

[0022] The segmented support mechanism 4 includes a central column 41, a segmented sleeve 42, a segmented plate 43, an elastic connecting ring 44 and an annular cavity 45. Several segmented sleeves 42 are equidi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com