Molded article and method for producing same

A manufacturing method and molding technology, which can be applied in the direction of coating, etc., can solve the problems of increased manufacturing cost, decreased optical properties of the molded body, and inappropriateness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 Embodiment approach

[0068] [2-1. Differences from the first embodiment]

[0069] Since the second embodiment has the same basic configuration as the first embodiment, the differences will be described below. In addition, the same reference numerals as those in the first embodiment denote the same structures, and refer to the previous description.

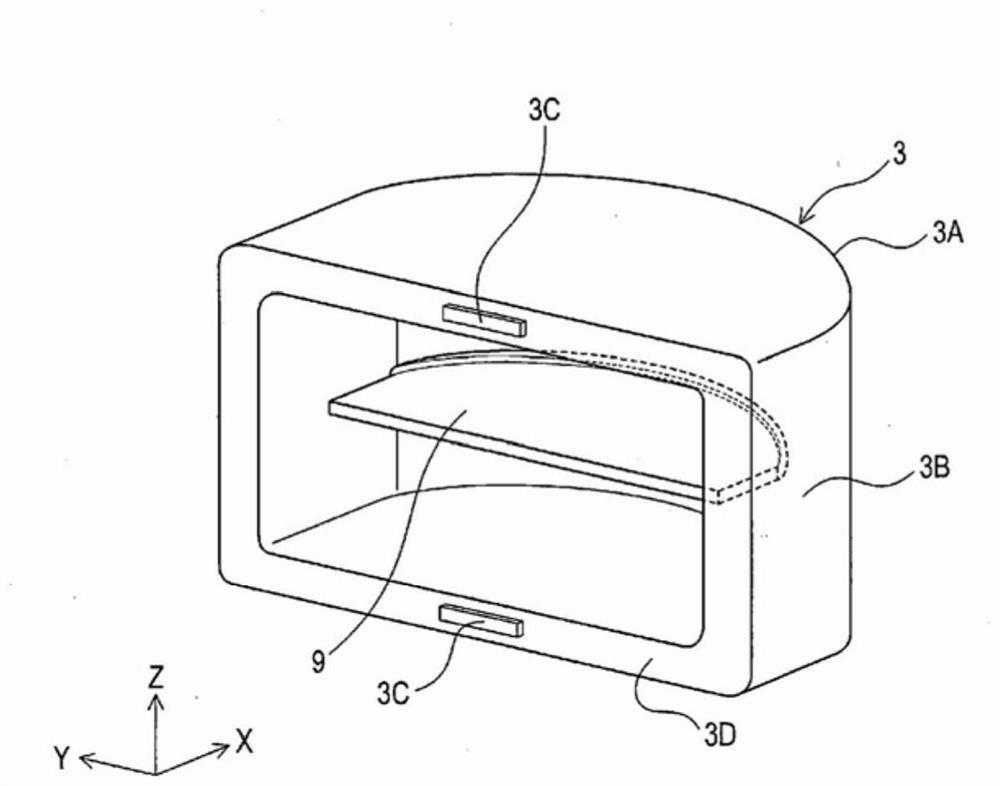

[0070] The cover portion 3 in the first embodiment is molded by injecting the first resin from a total of two gates G provided at positions corresponding to the center in the ±Y direction among the sides on the ±Z side of the base portion 3B. In contrast to this, as Figure 7 As shown, the cover portion 53 in the second embodiment is molded by injecting the first resin from a total of two gates G provided at positions corresponding to the +Y side of the base portion 53B separated in the ±Z direction. different. More specifically, the two gates G are arranged so as to sandwich the XY plane passing through the light shielding member 9 from the ±Z dire...

no. 3 Embodiment approach

[0076] [3-1. Differences from the first embodiment]

[0077] Since the basic structure of the third embodiment is the same as that of the first embodiment, the differences will be described below. In addition, the same reference numerals as those in the first embodiment denote the same structures, and refer to the previous description.

[0078] The cover portion 3 in the first embodiment is molded by injecting the first resin from a total of two gates G provided at positions corresponding to the center in the ±Y direction among the sides on the ±Z side of the base portion 3B. In contrast to this, as Figure 9 As shown, it differs in that the cover portion 63 in the third embodiment is molded by injecting the first resin from a gate G provided at a position corresponding to the center in the ±Y direction among the sides on the +Z side of the base portion 63B. When the cover portion 63 is molded using the first mold M1, the first resin such as Figure 9 flow as indicated by t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com