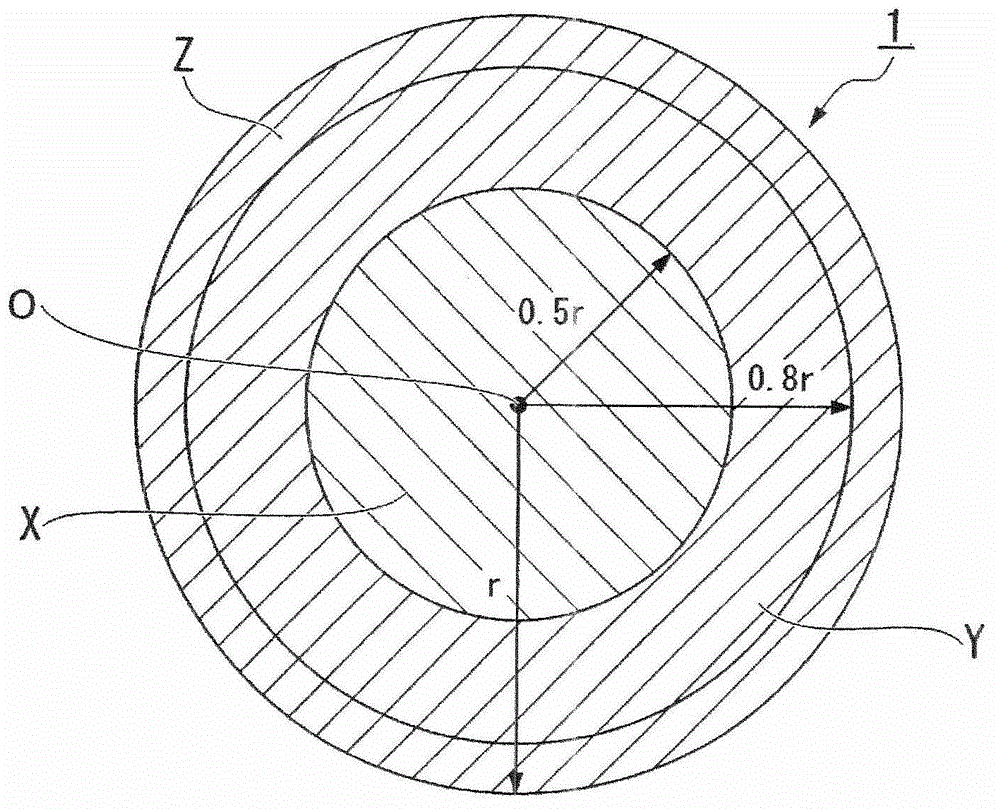

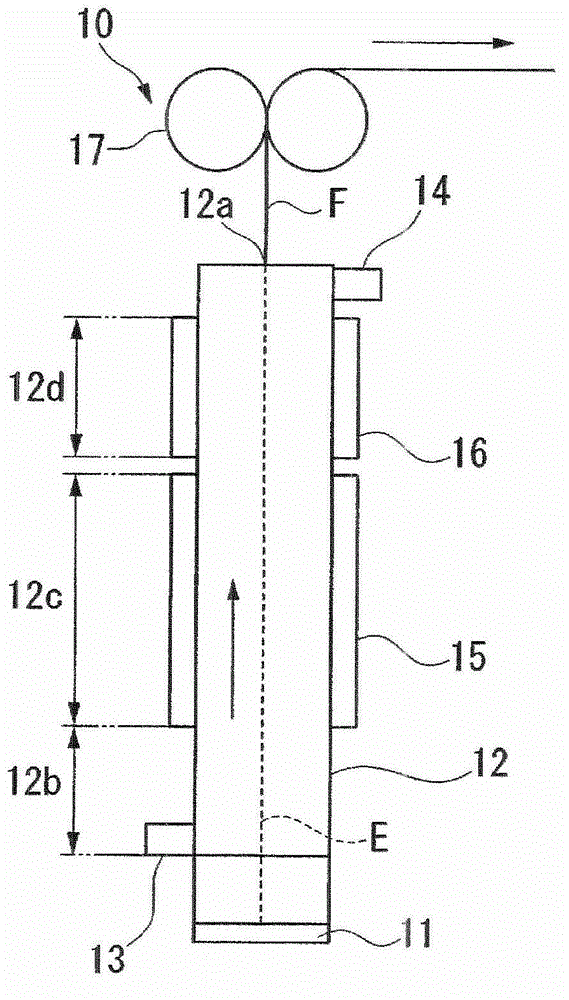

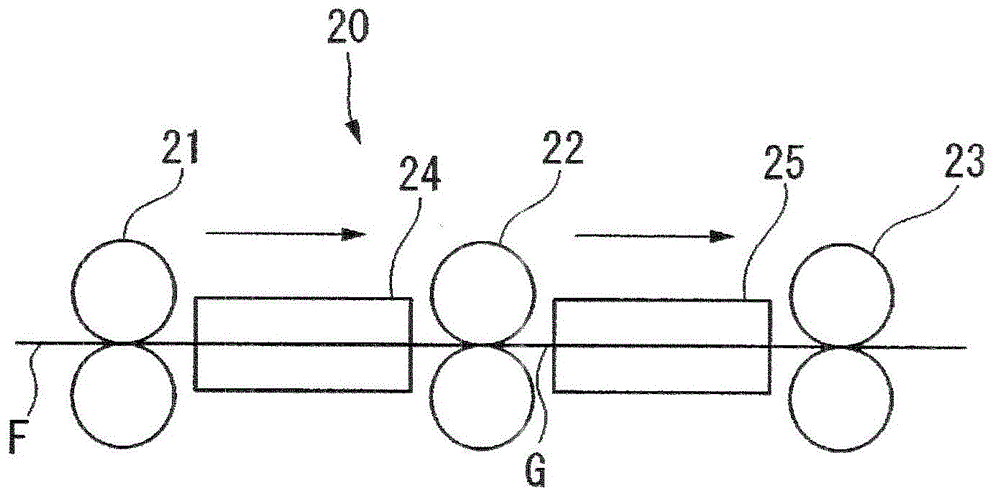

Plastic rod lens, plastic rod lens array, color image sensor head, and LED printer head

A rod lens, plastic technology, used in the field of LED print heads, which can solve problems such as the reduction of resolution or optical characteristics of luminous flux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0300] Hereinafter, an Example is given and this invention is demonstrated concretely. However, the present invention is not limited to these Examples.

[0301]

[0302] About the film of each polymer of sample No. 1-207, transparency was evaluated visually.

[0303]

[0304] Measurement was performed using an INTER-FACO interference microscope manufactured by Carl Zeiss Inc.

[0305]

[0306] Using a differential thermal analyzer (model: DSC6220C) manufactured by SII NanoTechnology Inc., the glass transition temperature (Tg) was measured under the following conditions.

[0307] ·Under nitrogen flow (flow rate 100mL / min)

[0308] ·Measurement temperature range: initial temperature 30°C, limit temperature 200°C

[0309] ·Heating rate: 10°C / min

[0310] In addition, the pretreatment of the evaluation sample is as follows.

[0311] Maintain the melted state of each polymer thin film or rod lens sample No. 1 to 207 at 150°C for 5 minutes, quench with dry ice for 1 minut...

manufacture example

[0327] 0.25 parts by mass of 1-hydroxycyclohexyl phenyl ketone (HCPK) as a photocuring catalyst was mixed with 100 parts by mass of the mixture of monomers and polymers shown in Tables 1 to 7, and sandwiched between two glass slides In between, by irradiating 5000mJ / cm 8 times with three 2kW high-pressure mercury lamps 2 It is cured by ultraviolet light to obtain a film-like polymer mixture sample No. 1-207 (a mixture of PMMA and other polymers) with a thickness of 0.3 mm.

[0328] Tables 1-5 show the results of evaluating the transparency, refractive index, and glass transition temperature of the polymer mixture for Sample Nos. 1-131. Among these results, the results of the triangular phase diagram for transparency are shown in Figure 5-9 In, further, the results after sorting out the content of the aromatic ring-containing monomer (a) and the content of the (meth)acrylate (b) unit having a branched hydrocarbon group with 3 or more carbon atoms are shown in Figure 10 midd...

Embodiment 1

[0345] 45 parts by mass of polymethyl methacrylate (PMMA), 20 parts by mass of methyl methacrylate (MMA), 35 parts by mass of phenyl methacrylate (PhMA), 1-hydroxycyclohexylbenzene 0.25 parts by mass of ketone (HCPK) and 0.1 part by mass of hydroquinone (HQ) were used to prepare a stock solution (uncured product) for forming the first layer. This composition is the same as that of sample No.5.

[0346] 45 parts by mass of PMMA, 40 parts by mass of MMA, 15 parts by mass of PhMA, 0.25 parts by mass of HCPK, and 0.1 part by mass of HQ were heated and kneaded at 70° C. to prepare a stock solution (uncured material) for forming a second layer. This composition is the same as that of sample No. 26.

[0347] 45 parts by mass of PMMA, 40 parts by mass of MMA, 7.5 parts by mass of PhMA, 7.5 parts by mass of 2,2,3,3-tetrafluoropropyl methacrylate (4FM), 0.25 parts by mass of HCPK, and HQ0 were heated and kneaded at 70°C. .1 part by mass to make a stock solution (uncured material) for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com