Drilling and hair planting all-in-one machine

An all-in-one machine and hair-planting technology, which is applied in the direction of brush body, brushes, cleaning methods and utensils, etc., can solve the problems of limited hair-planting methods, brush hairs drifting and falling, and waste of time, so as to improve adjustability and avoid brush hairs from being scattered Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

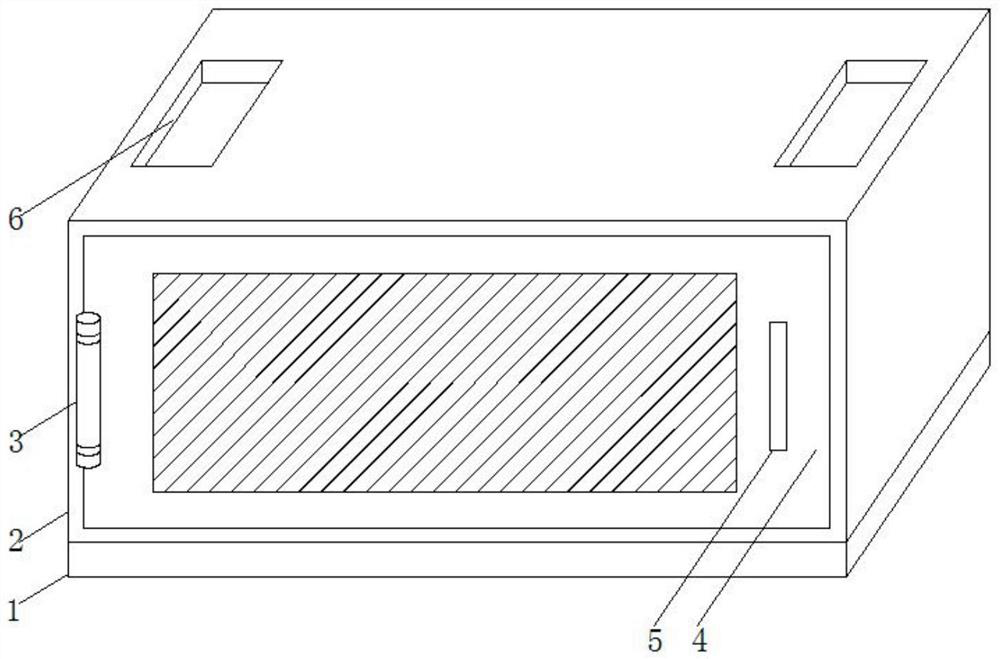

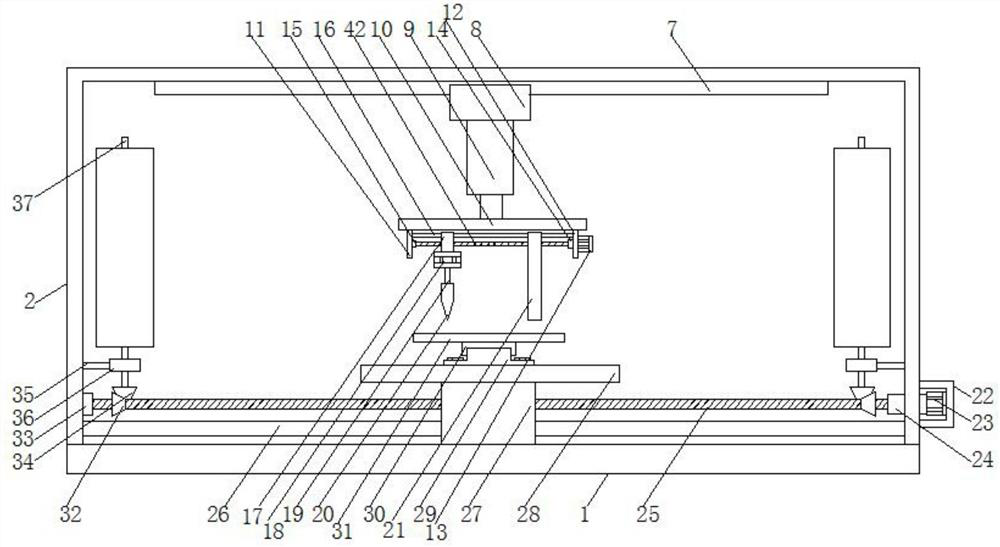

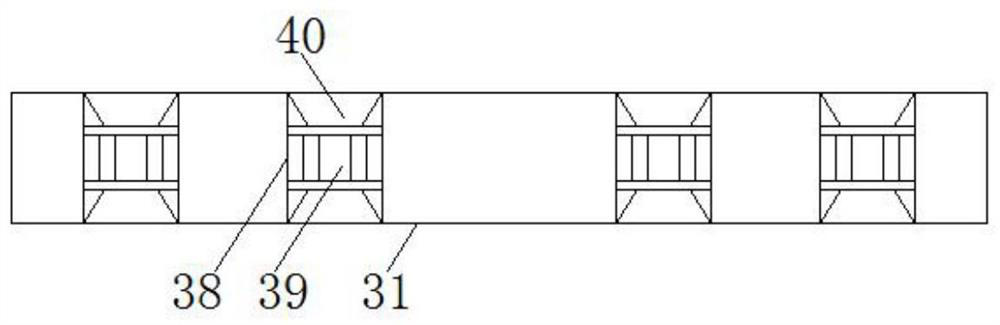

[0026] see Figure 1-4 , the present invention provides a technical solution: an integrated drilling and hair-planting machine, comprising a device bottom plate 1, and the top of the device bottom plate 1 is provided with a drilling and hair-planting integrated mechanism and a rotating mechanism;

[0027] The integrated drilling and hair planting mechanism includes a first electric sliding rail 7, a first electric sliding block 8, an electric telescopic cylinder 9, a first fixing plate 11, a second fixing plate 12, a first motor 13, a first motor shaft 14, The first threaded rod 42, the first bearing 15, the first moving block 17, the second motor 18, the second motor shaft 19, the rotating rod 37, the drill bit 20 and the hair planting head 21; the top of the device bottom plate 1 is bolted with a device Box 2, the top of the device box 2 is bolted with a first electric sliding rail 7, the bottom of the first electric sliding rail 7 is slidably connected with a first electric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com