Assembling method for internal parts of top-mounted fixed ball valve

A technology for fixing ball valves and assembly methods, which is applied in the direction of hand-held tools and manufacturing tools, can solve the problems of low disassembly efficiency and damage, and achieve the effects of simple and labor-saving assembly, improved reliability, and convenient assembly and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

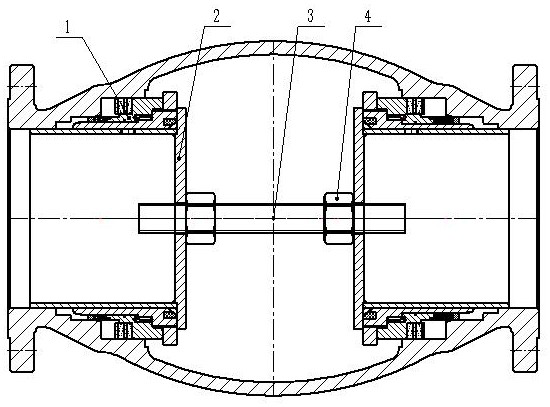

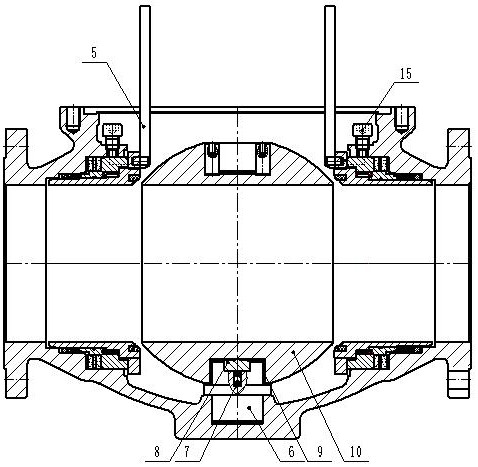

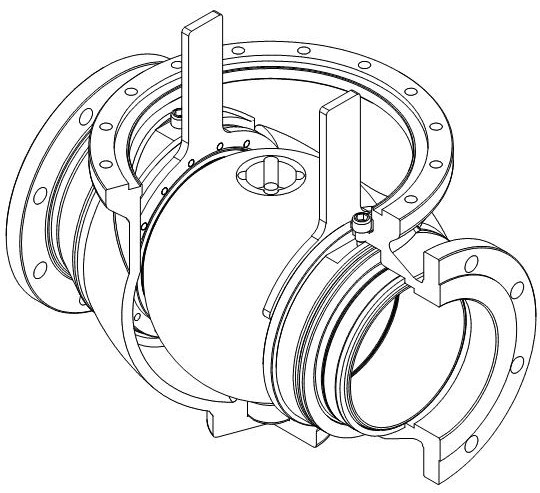

[0017] As shown in the figure, a method for assembling the internal parts of a top-loading fixed ball valve includes the following steps: Step 1: Load the valve seat assembly 1 on both sides and the guide tooling 2 on both sides from the middle channel, install the screw 3 and the nut 4; Step 2 : Rotate the nut 4 on both sides, generate a rotational force through the thread pair between the screw 3 and the nut 4, and push the nut 4 to the guide tooling 2 on both sides to open the valve seat assembly 1 on both sides; Step 3: Take out the screw 3, The nut 4 and the guide tool 2 are loaded into the lower valve shaft 6, the spring 7, the spacer 8, the bearing 9, and the ball 10 in sequence; Step 4: Insert the pin 14 of the pre-tightening handle 5 into the pin hole 19 on the side of the pre-tightening nut 18 In the middle, after rotating the pre-tightening handle 5 to make the pre-tightening nut 18 and the valve seat 17 have a retreat distance, install the anti-loosening screw 15 in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com