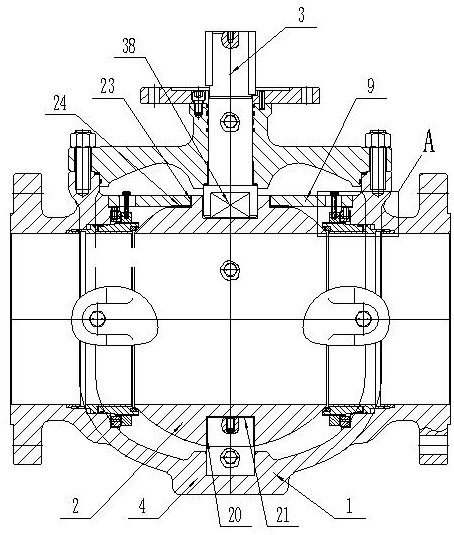

Top-mounted pipeline ball valve

A top-mounted, pipeline-based technology, applied to valve devices, cocks including cut-off devices, engine components, etc., can solve the problems of uneven stress on flange gaskets, bolt failure, bolt looseness, etc., and achieve reasonable design Excellent, easy and labor-saving assembly, and avoid torsional deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

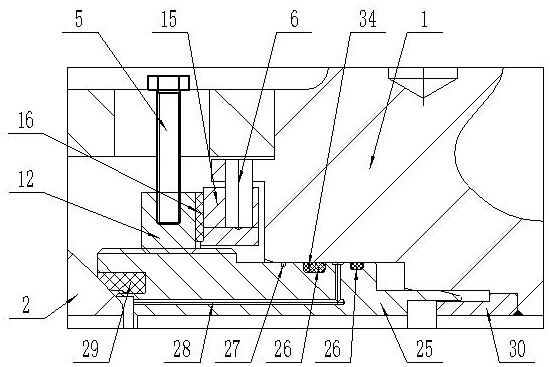

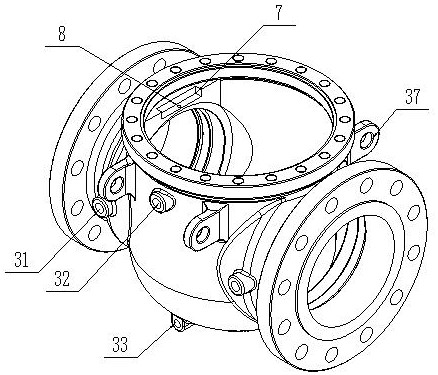

[0027] As shown in the figure, a top entry pipeline ball valve includes a valve body 1, a sphere 2, an upper valve shaft 3, a lower valve shaft 4, a limit screw 5, a limit pin 6, a seat support ring 25, a spring seat 15, Anti-rotation block 30, notch mortise 7 is provided above the channel both sides of valve body 1, limit hole 8 is provided on the plane of notch mortise 7, support plate 9 is housed on the notch mortise 7, and support plate 9 is symmetrically provided with anti-rotation block 30. The loose hole 10, the threaded hole I11, the limit screw 5 through the anti-loosening hole 10 and cooperates with the pre-tightening nut 12, the side of the pre-tightening nut 12 is provided with a blind hole 13 matched with the pin shaft on the pre-tightening tooling, pre-tightened The end of the tightening nut 12 is provided with a threaded hole II14 matched with the limit screw 5 to prevent the valve seat support ring 25 from loosening during the switching process of the ball 2 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com