Cabling construction method and apparatus

A cable laying and construction method technology, applied in the direction of cable laying equipment, etc., can solve the problems of inconvenient operation and complicated installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Specific embodiments according to the present invention are described in detail below.

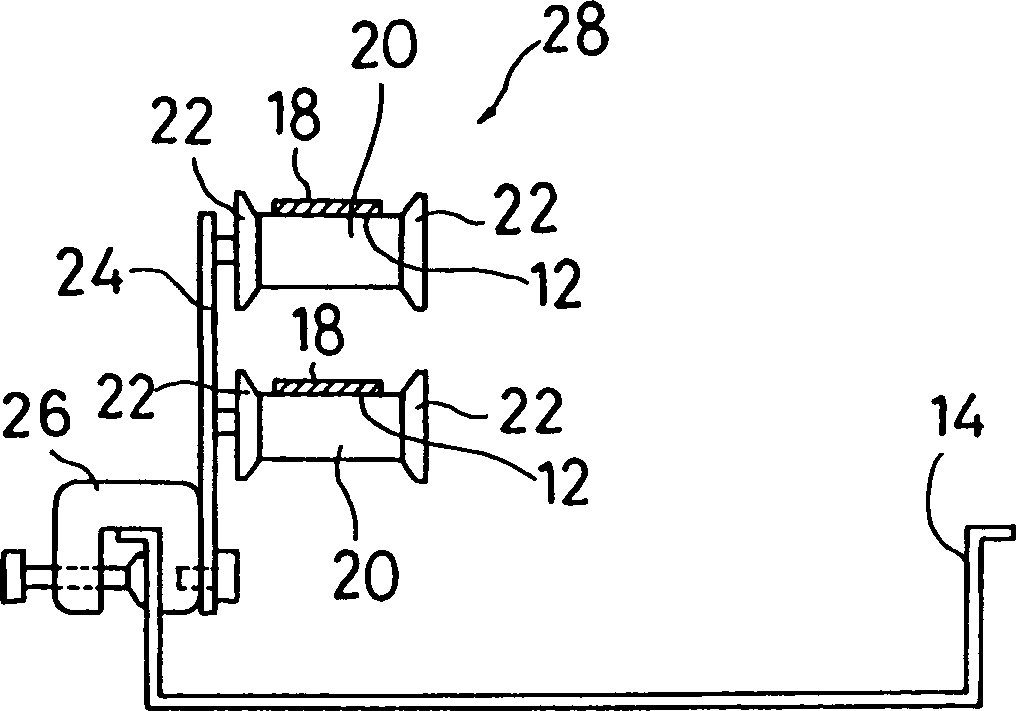

[0026] On the basis of careful consideration, the present invention achieves: when a belt follows the guide pulley, a stable attitude of the belt in operation can be obtained, and thus a power distribution conductor can be pulled reliably.

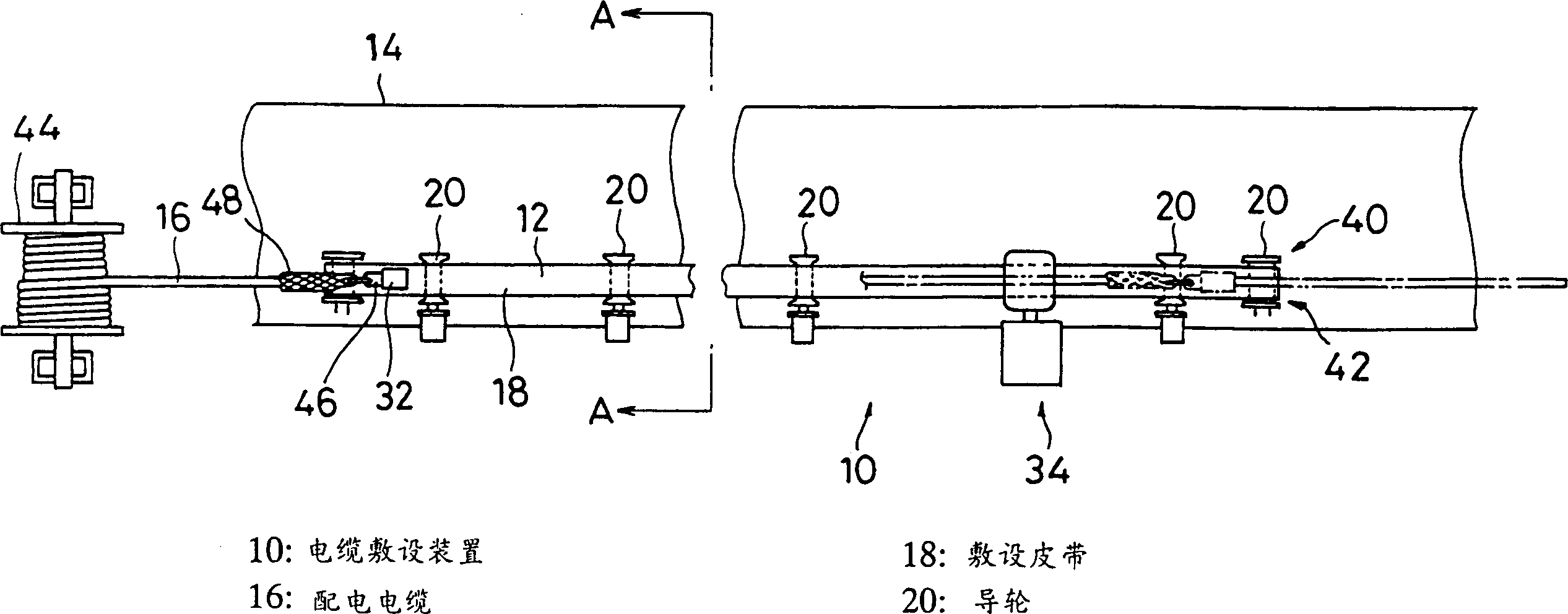

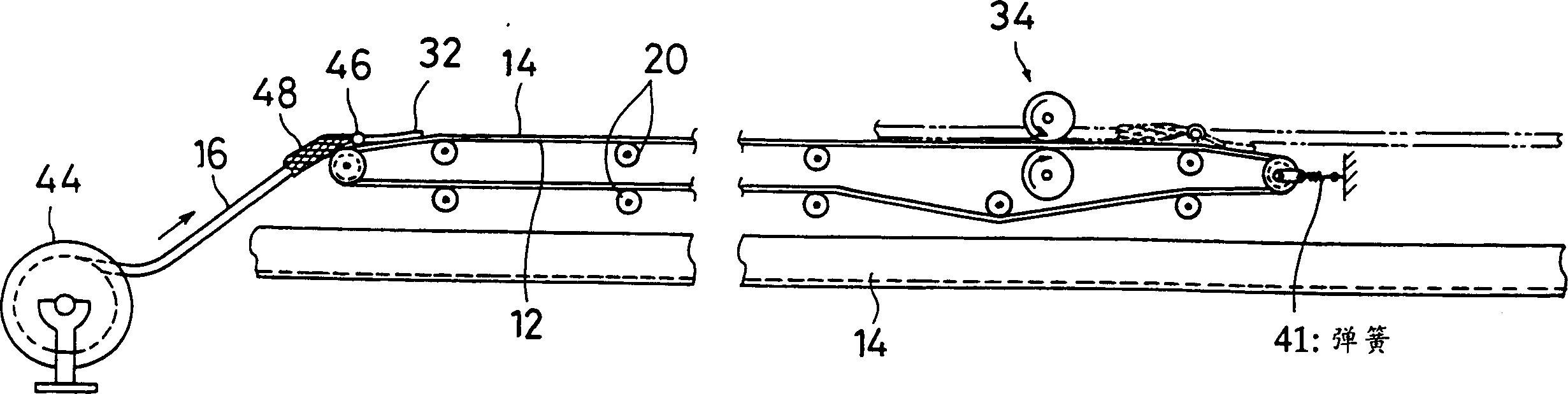

[0027] The construction method for laying cables according to the present invention includes the steps of: placing an endless laying belt along a cable laying route; connecting cables to a given point of the laying belt; running the laying belt to lay cables along the cable laying route. Here, a construction method may include the following steps: longitudinally placing a plurality of endless laying belts along the cable laying route; Detach from the laying belt; send out the removed cable again; connect the cable to the starting point side of the second laying belt after the cable leaves the first laying belt and arrive at the starting point si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com