Surface spraying device and spraying method for wooden door production

A surface spraying and wooden door technology, which is applied to the surface coating liquid device, spray device, cleaning method using tools, etc., can solve the problems of affecting the painting efficiency, inconvenient wooden doors, and unable to adjust the circular rotation of wooden doors, etc., to achieve improvement Spraying efficiency, improvement effect, effect of improving spraying processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

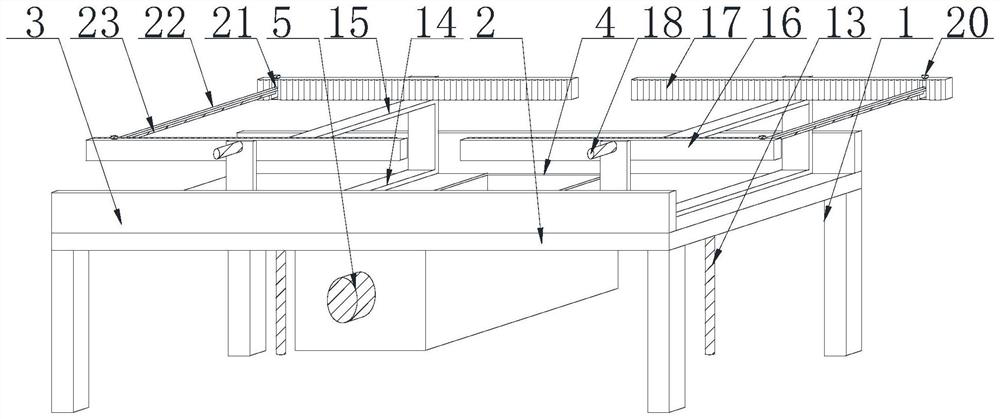

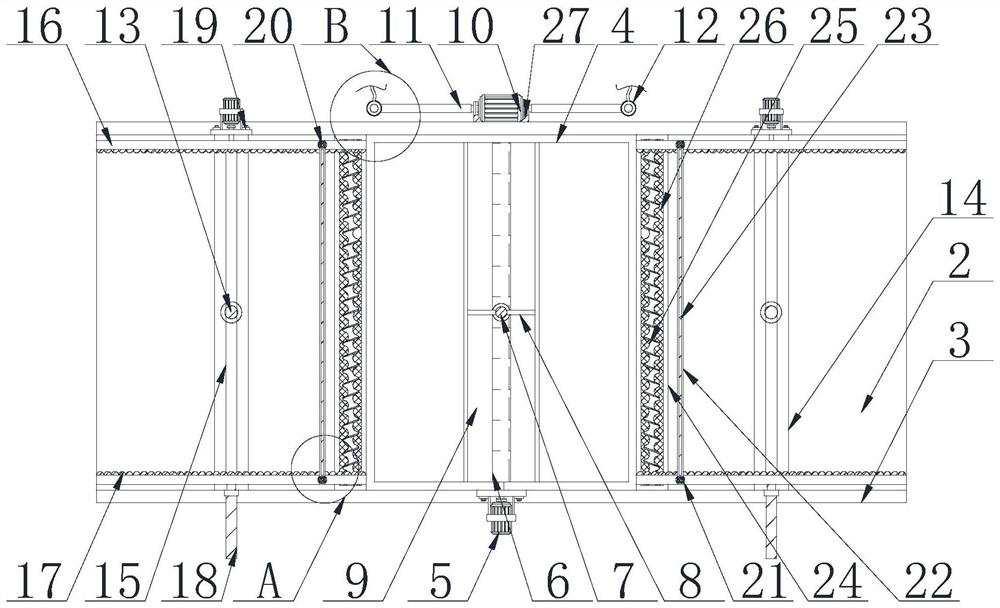

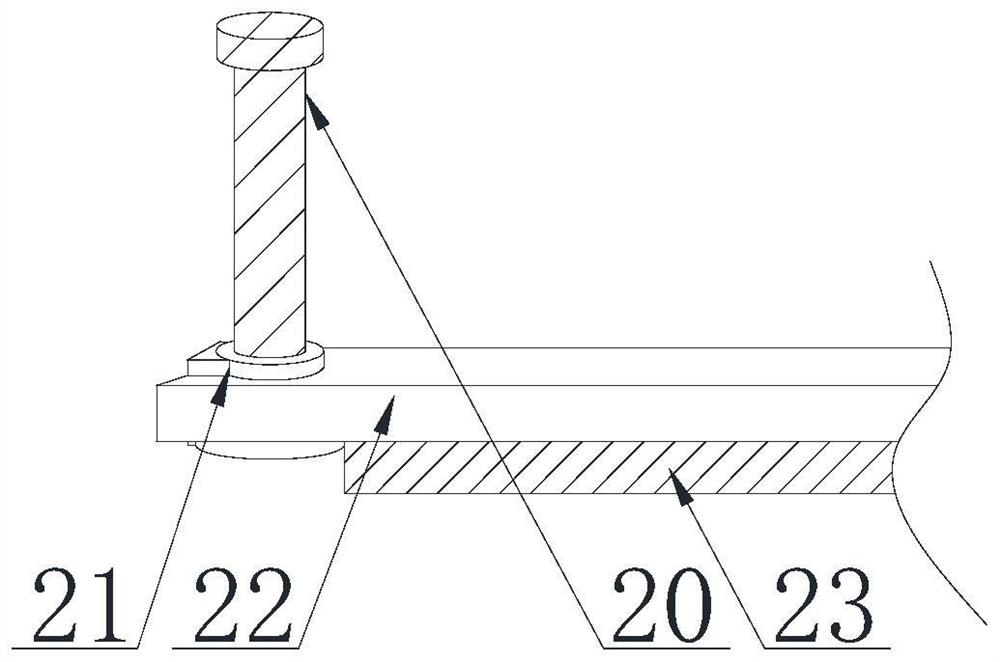

[0025] see Figure 1-5 , the present embodiment provides a surface spraying device for wooden door production, including four support columns 1, a bottom plate 2, a bidirectional synchronous motor 10, a connecting frame 11 and a nozzle 12, and a fixed frame 4 is fixedly connected in the inner middle of the bottom plate 2, A fixing frame 6 is rotatably connected to the inner middle of the fixing frame 4, and both sides of the fixing frame 6 are slidably connected to the limiting frame 9, and the fixing frame 6, which is rotatably connected between the inner ends of the fixing frame 4, is slidably connected to the fixing frame 6. The limit frames 9 on both sides are used for auxiliary support and movement adjustment when the wooden door is rotated and adjusted, thereby realizing the purpose of rotating and adjusting the wooden door at both ends of the bottom plate 2, thereby improving the processing efficiency of spraying;

[0026] The side walls on both sides of the bottom plat...

Embodiment 2

[0033] see Figure 1-5 , made further improvements on the basis of Example 1:

[0034] The protective frame 24 is fixedly connected to both sides of the top of the fixed frame 4 on the bottom plate 2, the heating wires 25 are fixedly connected to the inner middle of the protective frame 24, the filter screen 26 is fixedly connected to the top of the protective frame 24, and the protective frame 24 is respectively It is arranged below the opposite end of the limit plate 16, and is heated by the electric heating wire 25 fixedly connected to the inner middle of the protective frame 24, and then cooperates with the filter screen 26 fixedly connected to the top of the protective frame 24, so that the wooden door is rotated, adjusted and sprayed. It is convenient to cooperate with the heating and drying of the sprayed side, so as to achieve the effect of auxiliary drying, greatly improve the drying efficiency, and then facilitate the rotation adjustment and spraying processing of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com