Powder feeder for supersonic-speed flame spraying

A technology of supersonic flame and powder feeder, which is applied in coating, fusion spraying, metal material coating process, etc., can solve the problems of affecting spraying processing efficiency, unable to supply powder with multiple equipment, and high maintenance cost, and achieve production The effect of low manufacturing cost, convenient spraying and processing, and reduced equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

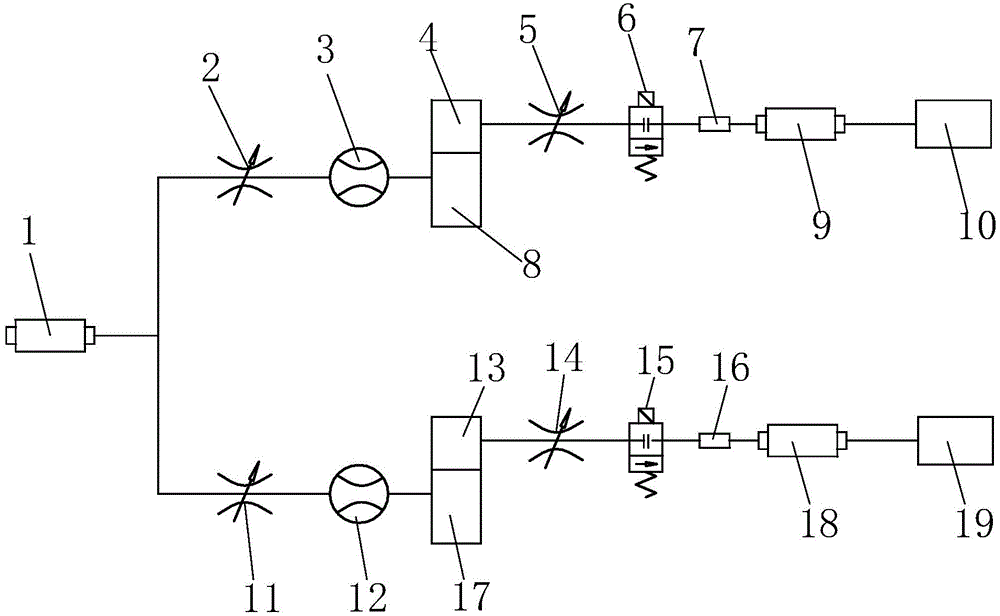

[0013] Such as figure 1 As shown, a powder feeder for supersonic flame spraying includes a first gas pipe joint 1, a first powder feeding branch and a second powder feeding branch, and the first gas pipe joint 1 is connected to the first powder feeding branch through pipelines respectively. The powder branch is connected with the second powder feeding branch. The present invention adopts the first powder feeding branch and the second powder feeding branch, which can respectively supply powder for two sets of supersonic flame spraying equipment, which makes up for the deficiencies in the prior art, and provides a better solution for the actual spraying process of the factory. It is convenient, reduces equipment investment, and reduces manufacturing costs.

[0014] The first powder feed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com