Steel coil spraying method and device

A technology for steel coils and coatings, which is applied to spray devices, devices for coating liquid on surfaces, coatings, etc., can solve the problems of annealing edge cracks, the inner ring and outer ring cannot be effectively sprayed, etc., to avoid annealing edge cracks, Guarantee the effect of spraying effect and accurate spraying position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

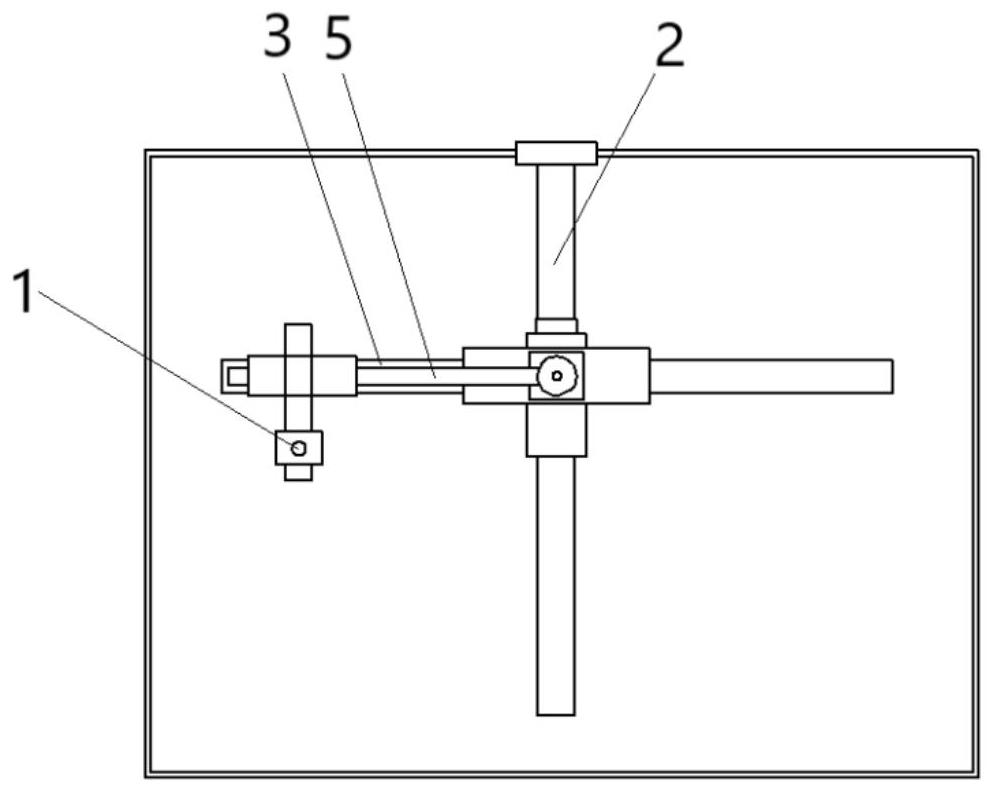

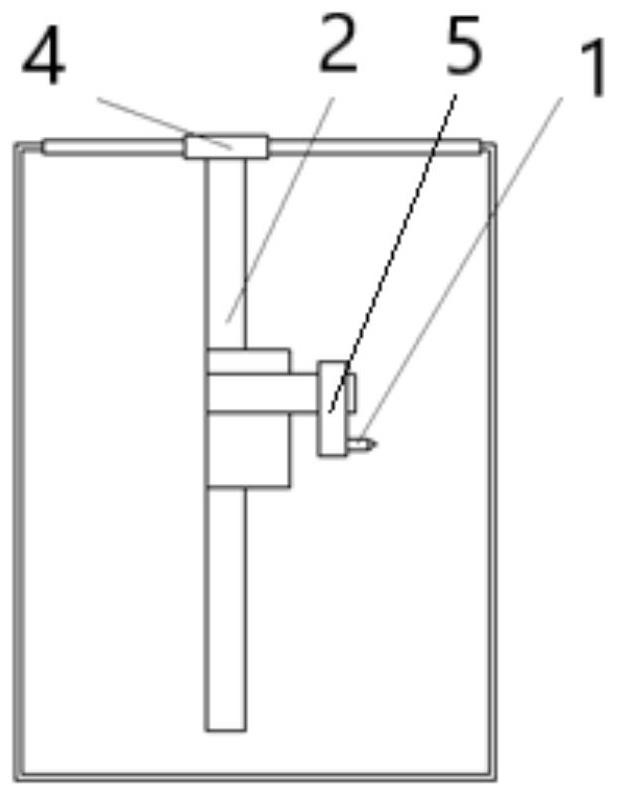

[0041] In order to make the application more clearly understood by those skilled in the technical field to which the application belongs, the technical solutions of the application are described in detail below with reference to the accompanying drawings and through specific embodiments.

[0042] During the hoisting process of the steel coil, the phenomenon of unwinding of the steel coil may occur, resulting in the flat coil defect of the steel coil. The shape of the steel coil with this defect is observed along the axis direction. Ellipse, and the long axis of the ellipse may be vertical or horizontal. For steel coils with flat coil defects, if the inner and outer ring diameters calculated according to the weight and thickness of the steel coil are sprayed, it may cause that some positions near the outer ring are not sprayed with anti-crack coating, and some positions are close to the axis. Does not play a role in preventing edge cracking.

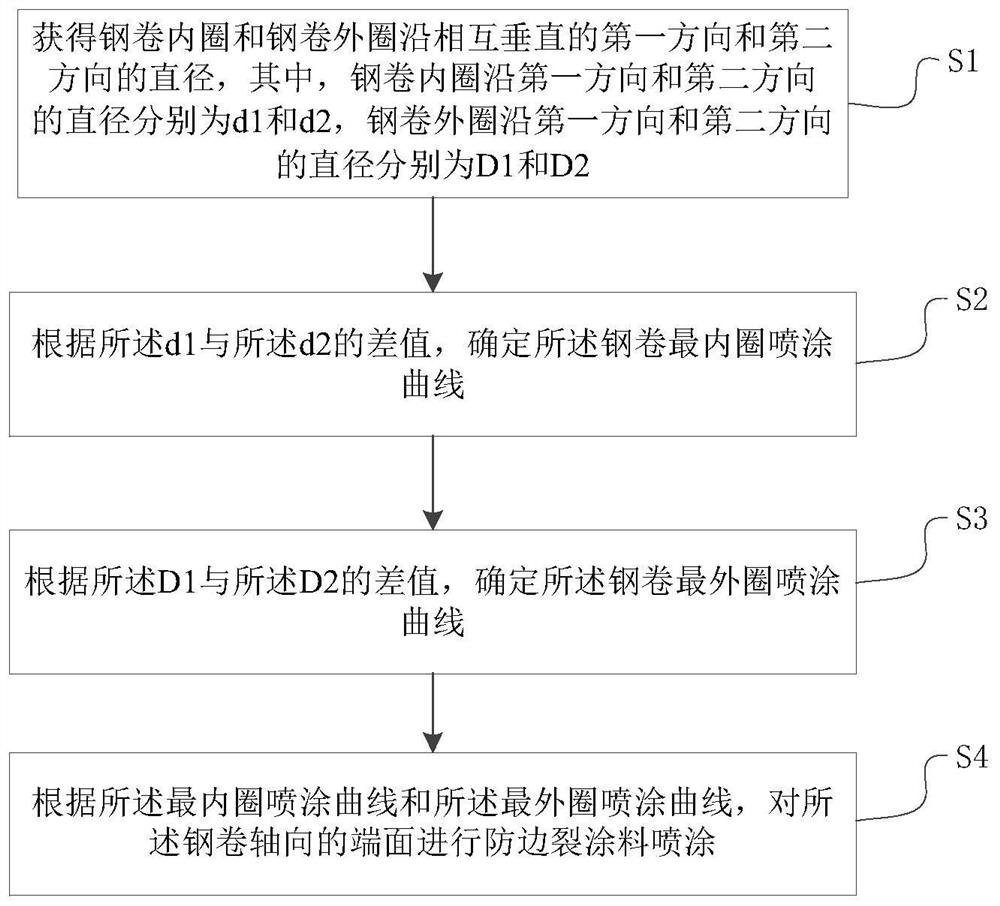

[0043] figure 1 A process step d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com